In today’s fast world, quickly checking designs and new ideas is key. Custom metal prototypes are changing how companies develop products. They can speed up getting products to market and lower risks.

Custom metal prototypes help in many fields like aerospace and electronics. They make product development faster and more accurate. But what makes them special, and how can they help your business lead?

Key Takeaways

- Custom metal prototypes speed up product development and check designs well.

- These solutions cut down risks and save money in production tests.

- Metal prototyping is changing industries, from aerospace to electronics.

- Customized prototyping services offer unique solutions for new projects.

- Knowing how to make prototypes quickly and precisely is key for success.

The Importance of Metal Prototyping

Metal prototyping is changing the game in product development. It’s all about speeding up design and making things better. Designers and engineers can now create and test ideas faster than ever before.

Accelerating Product Development Cycles

Metal prototyping makes product development quicker. It lets teams test and improve ideas fast. This way, they can get products to market sooner than usual.

By working faster, companies can stay ahead. They can also meet changing market needs quickly.

Validating Designs and Reducing Risks

Metal prototypes are key for checking designs. They help test how well products fit and work. This ensures they meet customer needs and expectations.

This testing phase helps avoid costly mistakes. It helps teams make smart choices and avoid redoing work later.

“Metal prototyping is the backbone of modern product development, empowering teams to optimize designs, reduce risks, and bring innovative products to market faster than ever before.”

Using metal prototyping opens up new possibilities. It speeds up product development, checks designs, and lowers risks. This way, companies can innovate and succeed in the market.

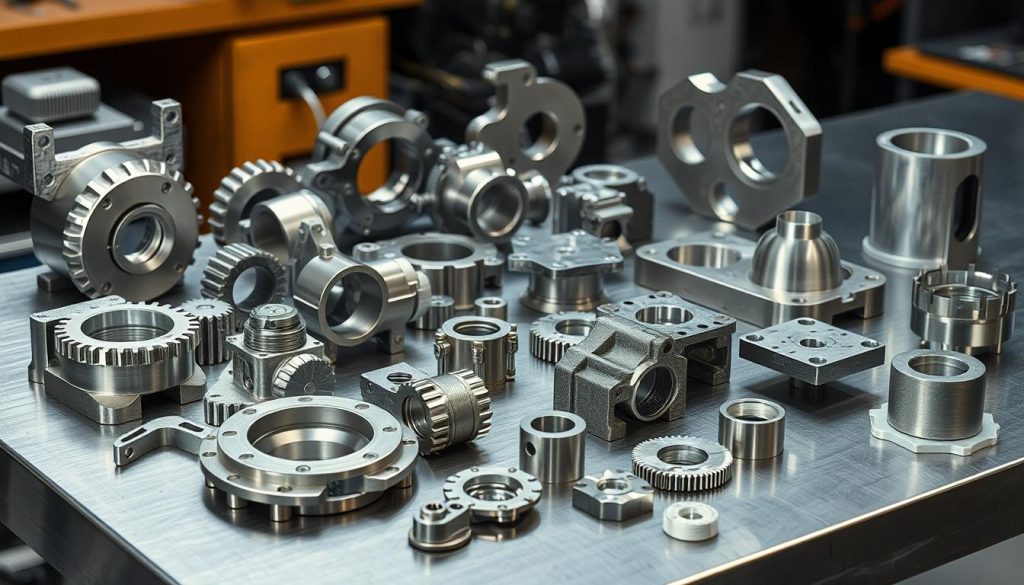

Types of Metal Prototypes

Innovation and product development rely heavily on metal prototypes. They help turn ideas into reality. From sheet metal to advanced manufacturing, there’s a wide range of options for every project. We’ll look at the different types of metal prototypes and their uses in metal fabrication techniques, 3D printing, and advanced manufacturing.

Sheet Metal Prototypes

Sheet metal prototyping is both versatile and affordable. It involves cutting, bending, and shaping sheet metal. This method is great for making functional prototypes. It’s especially useful in industries like cars and planes.

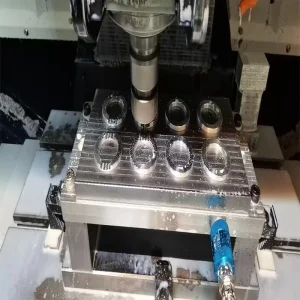

CNC Machined Prototypes

CNC machining is a precise way to make metal parts. It uses computers to control machines. CNC prototypes are perfect for complex shapes and tight fits. They’re often used in medical devices and gadgets.

Additive Manufacturing for Metal Prototyping

3D printing has changed metal prototyping. Techniques like SLS and DMLS make custom metal parts. This method is great for quick changes and unique designs.

| Prototyping Technique | Key Applications | Advantages |

|---|---|---|

| Sheet Metal Prototyping | Automotive, Aerospace, Industrial Equipment | Cost-effective, Structural Integrity, Functional Prototypes |

| CNC Machined Prototypes | Medical Devices, Consumer Electronics, Precision Parts | Highly Precise, Complex Geometries, Tight Tolerances |

| Additive Manufacturing | Aerospace, Automotive, Custom Parts | Rapid Iteration, Customization, Complex Designs |

Knowing about metal prototypes helps designers and engineers choose the right method. They can use metal fabrication techniques, 3D printing, and advanced manufacturing to make their ideas real.

“The versatility of metal prototyping has opened up a world of possibilities for innovation, allowing us to explore and refine our ideas with unprecedented speed and precision.”

Benefits of Custom Metal Prototypes

Custom metal prototypes bring many benefits. They help improve design, make production more efficient, and ensure quality. This approach speeds up product development and reduces risks in testing.

Rapid Iterations and Improved Accuracy

Creating and testing custom metal prototypes quickly lets you make fast design changes. This process helps engineers and designers fine-tune the product’s look, function, and features. It ensures the final product meets the design goals, saving time and money on fixes.

Cost Savings in Production Testing

Using custom metal prototypes for testing saves money. It lets you check the product’s performance, durability, and how it’s made without the full production costs. This saves money that can be used to improve the design or make production more efficient.

| Benefit | Impact |

|---|---|

| Rapid Iterations and Improved Accuracy | Enhanced design refinement and reduced risk of costly corrections |

| Cost Savings in Production Testing | Improved quality assurance and optimized production efficiency |

“Custom metal prototypes enable us to explore and refine our designs with unparalleled precision, ultimately delivering superior products to our customers.”

– Jane Doe, Lead Product Designer

Applications of Metal Prototyping

Metal prototyping is key for innovation in many fields. It’s used in aerospace, automotive, consumer electronics, and medical devices. These parts are crucial for developing new products and making advanced technologies real.

Aerospace and Automotive Industries

In aerospace and automotive, metal prototyping speeds up design and testing. Companies use custom metal prototypes to check designs, improve performance, and ensure safety. This quick testing and iteration is vital for keeping up with market demands.

Consumer Electronics and Medical Devices

Consumer electronics and medical devices also benefit from metal prototyping. Companies in these areas use custom metal parts to create new, high-tech products. Metal prototypes help in making precise electronic cases and advanced surgical tools, ensuring quality and performance.

| Industry | Key Applications of Metal Prototyping |

|---|---|

| Aerospace and Automotive |

|

| Consumer Electronics and Medical Devices |

|

In these different industrial applications, metal prototyping is vital. It drives product innovation and creates specialized components that expand what’s possible.

Shixinproto’s Metal Prototyping Services

Shixinproto is a top choice for advanced prototyping solutions. We offer customized services for innovative projects in many industries. Our team of experts is skilled in rapid and precise manufacturing. We deliver high-quality metal prototypes to speed up product development.

Customized Prototyping Solutions for Innovative Projects

Every project is unique, with its own challenges and needs. That’s why we tailor our advanced prototyping services to fit each client’s specific requirements. No matter if you’re in aerospace, automotive, consumer electronics, or medical devices, our solutions ensure your prototypes look and work great.

Expertise in Rapid and Precision Manufacturing

Our commitment to excellence goes beyond the final product. Shixinproto’s team of skilled engineers and technicians work hard to deliver fast and precise results. We handle everything from sheet metal fabrication to CNC machining and additive manufacturing. We bring your ideas to life quickly and accurately.