In the world of metal fabrication and manufacturing, the surface finish is key. Brushing surface finish is a popular method that stands out. It’s used in many fields, like automotive, aerospace, architecture, and home decor. This article will explore brushing surface finish, its benefits, and its uses.

Brushing surface finish adds a uniform, linear pattern to metal. It boosts the metal’s look and makes it last longer. Whether you work with metal, design products, or love DIY projects, knowing about brushing surface finish is important.

We’ll discuss brushing surface finish in detail. Topics include different brushing techniques and its benefits. By the end, you’ll understand how it can improve your metalwork.

What is a Brushing Surface Finish?

A brushing surface finish makes metal surfaces look better and work better. It uses abrasive brushes to create a unique brushed texture. This finish is great for many manufacturing applications because it makes the metal look good and last longer.

How Brushing Surface Finish Improves Metal Appearance and Performance

The brushing process gets rid of the metal’s natural oxide layer. This exposes a fresh, even surface. The result is a clean, linear pattern that can be tailored to different tastes. It also makes the metal easier to grip and feel, perfect for places where you need a non-slip surface.

Common Applications of Brushing Finish in Manufacturing

- Automotive industry: Brushed finishes are used on car parts like grilles, trim, and door handles. They make the car look better.

- Appliance manufacturing: Brushed finishes are popular on appliances like fridges, ovens, and dishwashers. They give a sleek, modern look and a better brushed texture.

- Architectural applications: Brushed metal finishes are used in building design, like on door frames, elevator panels, and decorations. They make buildings look good and last long.

| Industry | Application | Benefit |

|---|---|---|

| Automotive | Grilles, trim pieces, door handles | Enhances metal appearance and provides a non-slip surface |

| Appliances | Refrigerators, ovens, dishwashers | Offers a sleek, modern look and improved durability |

| Architecture | Door frames, elevator panels, decorative elements | Creates a visually appealing and durable finish |

Types of Brushing Surface Finishes

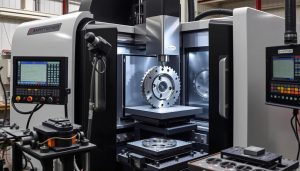

Businesses have two main choices for polishing metal parts: hand brushing and machine brushing. Each method has its own benefits. It’s important to pick the right one for your project.

Hand Brushing vs. Machine Brushing

Hand brushing is detailed and requires a lot of work. It lets experts use brushes to get the perfect finish. It’s great for small jobs, special finishes, or unique designs.

Machine brushing is faster and better for big orders. Machines can do the same job over and over, quickly. They work well with many materials and give consistent results.

Different Materials Suitable for Brushing Finishes

Brushing works on many materials like stainless steel, aluminum, and brass. Each material looks different when brushed. You need to think about the material and look you want when choosing a brushing technique.

Choosing the Right Brushing Technique for Your Project

Deciding between hand brushing and machine brushing depends on your project. Consider how big the job is, how complex the design is, and how much you want to customize. Knowing the pros and cons of each helps you choose the best option for quality, speed, and cost.

The Benefits of Brushing Surface Finish

Brushing surface finish is a top choice in metal fabrication and finishing. It boosts durability and corrosion resistance and is cost-effective. These benefits make brushing a standout option.

How Brushing Increases Durability and Corrosion Resistance

Brushing creates a unique texture that looks great and lasts longer. It seals the metal’s surface, protecting it from weather, wear, and chemicals. This means your product will last longer without needing constant upkeep.

Cost-Effectiveness of Brushing vs Other Finishing Methods

Brushing is cheaper than polishing or painting. It needs less equipment and takes less time, saving on costs. Plus, its durability and resistance to corrosion mean your product will last longer, saving you money in the long run.

“Brushing surface finish is a game-changer for manufacturers looking to strike the perfect balance between quality, performance, and cost-effectiveness.”

Knowing the perks of brushing helps manufacturers choose wisely. It’s great for making products that last and look good, all while keeping costs down. Brushing is a top pick for many industries.

How Brushing Enhances Product Performance

The brushing surface finish is more than just looks; it boosts a product’s performance and lasts longer. Brushing improves coating adhesion and makes a uniform texture for better aesthetic appeal.

Improving Adhesion for Coatings and Paints

Brushing makes a surface slightly rough. This helps coatings and paints stick better. The rough surface gives more area for the coating to hold onto, making the bond stronger and more lasting.

This is key for products facing tough environments or heavy use. It stops the finish from peeling, chipping, or flaking off.

Creating a Uniform Texture for Aesthetic Appeal

Brushing also makes the product look good and have a uniform texture. This texture makes the product more visually appealing. It looks clean and modern, fitting well with many designs.

This is why brushed finishes are popular for products like appliances and furniture. They add a touch of elegance and style.

| Benefit | Description |

|---|---|

| Improved Coating Adhesion | The textured surface created by brushing provides more surface area for coatings and paints to grip onto, resulting in a stronger, more durable bond. |

| Uniform Texture | Brushing creates a consistent, visually appealing texture that can enhance the aesthetic appeal of the finished product. |

Challenges in Brushing Surface Finishing

Brushing can make metal surfaces look better and work better. But, it comes with its own set of problems. Knowing these challenges is key to a successful brushing project.

Common Issues and Solutions in Brushing Finishes

Getting a smooth, even pattern on the surface is hard. If the brushing isn’t even, it can look bad. To fix this, use the right brushing technique and keep your brush in good shape.

Brushing too much can damage the surface and take off too much material. Watch how much you brush and only do what’s needed for the finish you want.

When to Avoid Using Brushing Surface Finish

Brushing is great for many things, but not for everything. It’s not good for small, tricky spots or hard-to-reach areas. For these, try polishing or electroplating instead.

Also, brushing isn’t best for very shiny or mirror-like finishes. For these, buffing or chemical etching might be better.

Knowing the surface finishing challenges and brushing limitations helps manufacturers pick the right method for their projects.

Why Choose Shixinproto for Your Surface Finishing Needs?

Shixinproto is a top choice for professional surface finishing. They have years of experience in brushing and other metal finishing techniques. Their focus on quality and customer happiness is unmatched, making sure your projects get the best care.

Shixinproto uses the latest equipment and has a team of experts. They are known for their reliable results and commitment to excellence. Whether you need a brushed finish for looks or a tough coating for performance, they can do it.

Choosing Shixinproto means your project is in good hands. They are always looking to improve, so you get the latest techniques and solutions. With Shixinproto, you can count on professional service and attention to detail for your surface finishing needs.

FAQ

What is a brushing surface finish?

A brushing surface finish is a way to make metal look and work better. It uses a wire brush to add a textured pattern. This makes the metal last longer, resist corrosion, and stick better to coatings or paints.

How does brushing surface finish improve metal appearance and performance?

Brushing makes metal look unique with a texture that can be subtle or bold. It also makes the metal stronger and more resistant to scratches and corrosion. This is why it’s used in many fields, from cars to buildings.

What are the common applications of brushing finish in manufacturing?

Brushing is used in many areas like cars, appliances, furniture, and electronics. It’s applied to metals like stainless steel and aluminum to improve looks and function.

What are the differences between hand brushing and machine brushing?

Hand brushing uses a brush to create a finish, while machine brushing uses automated tools. Hand brushing is good for small, detailed work. Machine brushing is better for large, uniform areas.

What materials are suitable for brushing surface finishes?

Metals like stainless steel, aluminum, and brass work well with brushing. The right material depends on the use and look you want.

How does brushing surface finish increase durability and corrosion resistance?

Brushing makes metal surfaces more durable and resistant to corrosion. The texture helps hide small scratches and channels liquids away, reducing corrosion.

Is brushing surface finish a cost-effective finishing method?

Yes, brushing is cheaper than polishing or painting. It’s quick and simple, saving on labor and materials. Brushed surfaces also last longer, saving on maintenance costs.

How does brushing improve adhesion for coatings and paints?

Brushing creates a surface that coatings and paints stick to better. The texture and increased area help the bond, making the finish last longer.

What are some common challenges in brushing surface finishing?

Challenges include getting a consistent pattern and avoiding over-brushing. Proper preparation is also key to avoid defects. Experienced finishers use special techniques to overcome these issues.

When should brushing surface finish be avoided?

Avoid brushing for smooth, reflective finishes or complex shapes. For these, polishing or electroplating might be better.