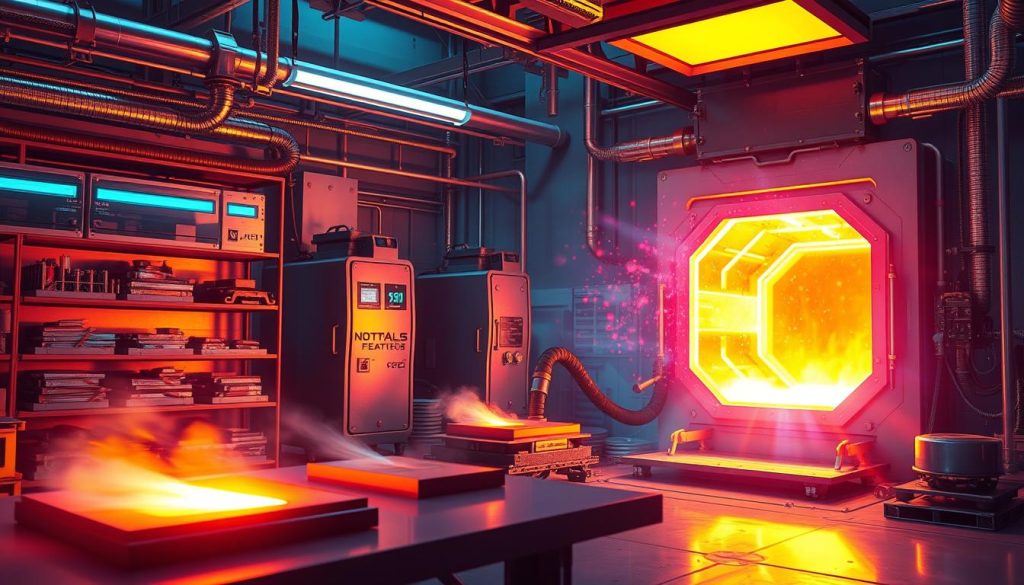

In the world of metallurgy and material science, heat treatment is key. It unlocks metals’ full potential. This guide explores how heat changes metal properties and performance.

Heat treatment boosts strength, durability, and wear resistance. It’s vital for modern engineering and manufacturing.

Ever wondered about heat treatment? How it meets industry needs? Let’s dive into this thermal processing technique. We’ll look at its basics, goals, and methods that shape our world.

What is Heat Treatment?

Heat treatment changes the microstructure and properties of metals. It uses heating and cooling cycles to do this. This method lets engineers change metals, opening up new possibilities for metal modification, property enhancement, and microstructure alteration.

Definition and Purpose of Heat Treatment

Heat treatment involves heating metals in a controlled way. It then cools them down slowly. This process changes the metal’s structure, making it stronger, harder, or more flexible.

Common Goals: Hardness, Strength, and Ductility

The main goals of heat treatment are to improve hardness, strength, and ductility. By managing the thermal cycles well, experts can make the metal fit the needs of different projects.

- Hardness: Making the metal more resistant to scratches and abrasion.

- Strength: Helping the metal handle forces better without breaking.

- Ductility: Allowing the metal to bend without breaking.

By using heat treatment, engineers can make metals better for many industries. This includes aerospace, automotive, medical devices, and construction.

Types of Heat Treatment Processes

In metallurgy, heat treatment is key to improving metal properties. It can soften metals for easier machining or make them harder and more durable. Let’s look at the main heat treatment methods used in industry.

Annealing: Softening Metals for Machining

Annealing heats a metal to a certain temperature, then cools it slowly. This makes the metal softer and more ductile, perfect for machining. It’s great for metals that have been hardened too much, as it brings back their original state.

Quenching: Enhancing Hardness and Durability

Quenching rapidly cools a metal in a liquid like water or oil. This makes the metal harder and stronger, better for withstanding wear. It’s mainly used on steels and alloys to boost their durability and performance.

Tempering: Balancing Hardness and Toughness

After quenching, the metal might be too brittle. Tempering fixes this by reheating and cooling the metal. It balances hardness and toughness, making the metal more versatile for different uses.

Case Hardening: Strengthening Surface Layers

Case hardening makes the outer layer of a metal hard, while keeping the inside soft. It involves adding carbon or nitrogen to the surface, then quenching and tempering. This is useful for parts like gears and bearings, where a hard surface is needed but the core must remain ductile.

These heat treatment methods, like annealing, quenching, tempering, and case hardening, are vital in metalworking. By controlling heat and cooling, manufacturers can adjust metal properties for specific needs. This can range from easier machining to better durability and performance.

Benefits of Heat Treatment

Heat treatment is a versatile process that unlocks many benefits for metal components. It enhances their performance and longevity. By controlling temperature and cooling rate, it makes metals more resilient and durable.

Improved Mechanical Properties

Heat treatment greatly improves metal performance. It does this through processes like annealing, quenching, and tempering. These processes optimize the material’s microstructure.

This results in increased tensile strength, yield strength, and hardness. Components become stronger and can handle more stress. They perform reliably and last longer in tough applications.

Enhanced Wear Resistance

Heat treatment also boosts metal durability. Techniques like case hardening change the material’s surface properties. This makes the metal more resistant to wear and tear.

With better wear resistance, parts last longer. They need less frequent replacements and maintenance. This saves time and money.

Stress Relief for Improved Stability

Heat treatment also relieves internal stress in metals. This material optimization process prevents distortion, cracking, or warping. It ensures the product’s dimensions stay stable.

Stress-relieved components are more predictable and reliable. They perform better over their lifetime. This makes them ideal for demanding applications.

By using heat treatment, manufacturers can create stronger, more durable products. These products are better suited for their intended use.

Applications of Heat Treatment

Heat-treated metals are used in many industries. They include aerospace, automotive, construction, and medical devices. By controlling temperature and cooling rates, metals get the right properties for their jobs.

Aerospace and Automotive Components

In aerospace, heat treatment makes parts strong for extreme conditions. Annealed aluminum alloys are perfect for aircraft. They are strong, durable, and light.

In cars, heat-treated steel makes frames, suspension, and brakes safe. It keeps drivers and passengers safe.

Construction and Tooling Industries

Construction materials get stronger with heat treatment. Steel beams, bars, and fasteners are treated to resist weather and corrosion. Tools like drill bits and saws also benefit from heat-treated metals.

Medical Devices and Precision Parts

Heat treatment is key for medical tools. Titanium alloys in implants are treated for strength and to resist corrosion. Stainless steel surgical tools and syringes need to stay sharp and strong.

| Industry | Heat-Treated Metal Applications | Key Benefits |

|---|---|---|

| Aerospace | Aircraft fuselages, wings, engine parts | Strength, durability, lightweight |

| Automotive | Frames, suspension systems, brake components | Strength, safety, corrosion resistance |

| Construction | Structural steel beams, reinforcing bars, fasteners | Strength, weathering resistance, stress tolerance |

| Medical | Orthopedic implants, surgical tools, syringes | Strength, corrosion resistance, biocompatibility |

Heat-treated metals are heroes in many fields. They make critical parts for aerospace, cars, construction, and medicine. They are essential for many industrial applications, aerospace materials, automotive engineering, construction metals, and medical instruments.

“Heat treatment is the key to unlocking the full potential of metals, transforming raw materials into high-performance components that shape our modern world.”

Shixinproto’s Expertise in Heat Treatment

At Shixinproto, we’re all about delivering top-notch heat treatment services. Our modern facilities and skilled metallurgists are ready to help with your metal projects. We aim for the best performance and long life of your treated parts.

High-Quality Heat Treatment for Custom Metal Projects

Our team at Shixinproto is a leader in thermal processing. We know each metal project is different. So, we create a heat treatment plan just for you.

Our experts work with you to solve your specific problems. Whether it’s making your metal parts harder, stronger, or more flexible, we’ve got you covered.

Tailored Solutions for Your Specific Needs

Quality assurance is key to our success at Shixinproto. We’re dedicated to providing the best custom heat treatment services. Our modern equipment and strict quality checks show our commitment.

With our deep industry knowledge and advanced technology, we guarantee outstanding results. Your metal projects will perform at their best, thanks to us.