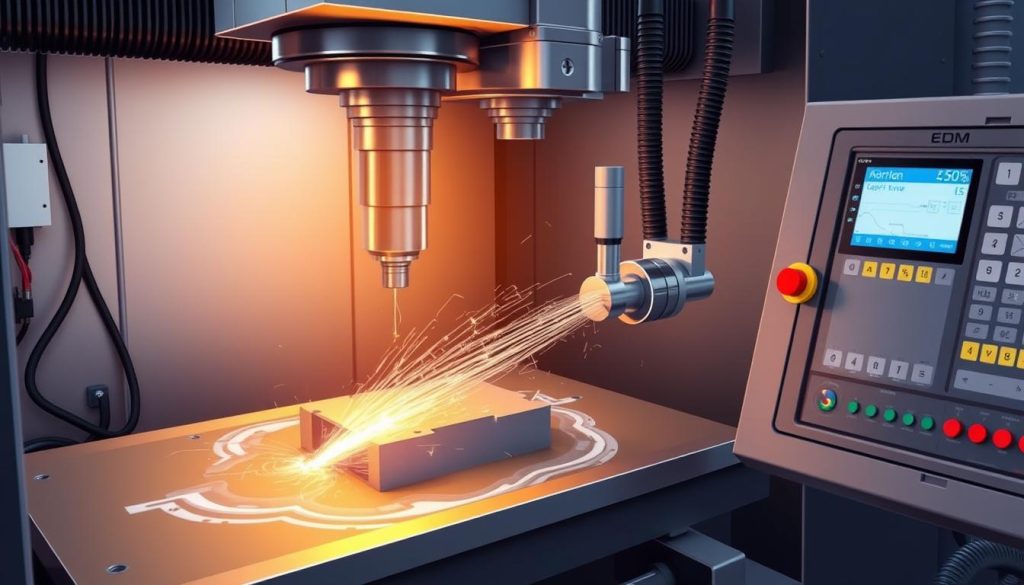

In the world of precision manufacturing, Electrical Discharge Machining (EDM) stands out. It’s a cutting-edge technology that lets engineers make complex shapes in hard metals with great accuracy. Get ready to explore EDM and see how it changes the game.

Imagine creating parts that go beyond what traditional machining can do. How would that change your manufacturing and the products you make? Find out as we dive into the world of Electrical Discharge Machining.

What is Electrical Discharge Machining (EDM)?

Electrical discharge machining (EDM) is a special way to make things. It uses electrical sparks to remove material from a workpiece. This method doesn’t need physical contact between the tool and the material.

Instead, it uses the heat from quick electrical sparks to wear down the workpiece. This makes it possible to create complex and precise shapes.

Overview of the EDM Process

The EDM process uses electrical discharges to erode the workpiece material. An electrode, often made of graphite or copper, moves along a set path. A dielectric fluid, like deionized water or oil, keeps the gap between the electrode and workpiece insulated.

This fluid also helps to wash away the material that’s been removed.

Key Components: Electrodes, Dielectric Fluid, and Workpiece

The main parts of an EDM system are:

- Electrodes: These tools, usually graphite or copper, guide the electrical discharges and shape the workpiece.

- Dielectric Fluid: The insulating fluid, like deionized water or oil, controls the electrical discharges and removes the eroded material.

- Workpiece: The material to be machined, which can be many hard or conductive metals, is in the dielectric fluid and gets the electrical discharges.

“Electrical discharge machining is a revolutionary manufacturing technique that allows us to create intricate and precise parts without the limitations of traditional machining methods.”

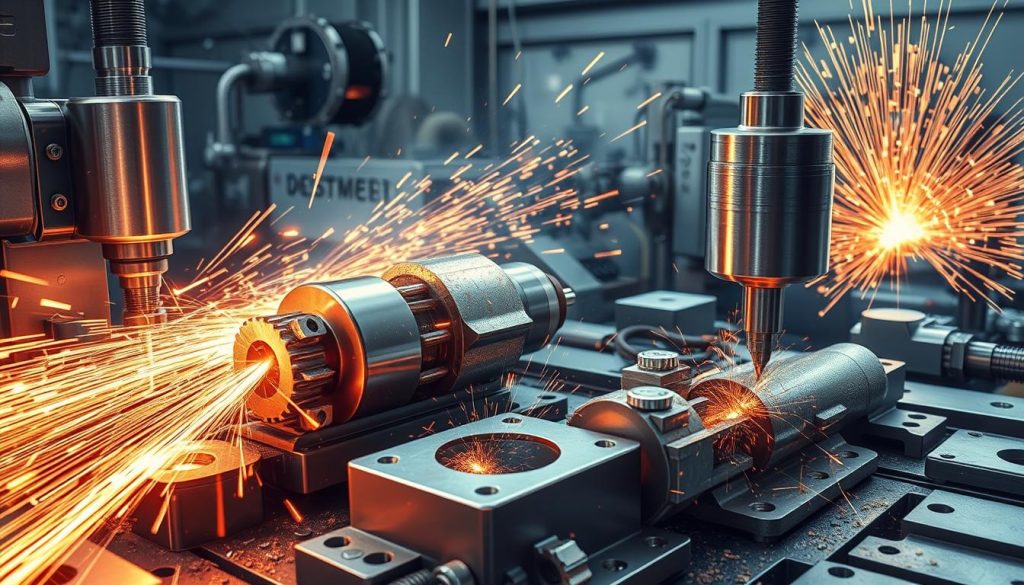

Types of EDM

Electrical Discharge Machining (EDM) has many techniques for different needs. The main ones are Wire EDM, Sinker EDM, and Hole Drilling EDM. These methods help shape and machine hard materials precisely.

Wire EDM

Wire EDM uses a thin wire to cut the workpiece with electrical discharges. It’s great for making detailed shapes. This makes it perfect for making tools, dies, and other precise parts.

Its accuracy is unmatched, making it a favorite in aerospace, automotive, and electronics.

Sinker EDM

Sinker EDM uses a shaped electrode to create complex shapes. It’s great for making molds and dies. This method is key for making parts that are hard to make with traditional methods.

It’s used in automotive, aerospace, and medical device making because of its precision.

Hole Drilling EDM

Hole Drilling EDM is for making small, deep holes in hard materials. It uses a tubular electrode to do this. This is important for making parts like fuel injectors and electronic packaging.

It’s used in aerospace, automotive, and electronics for its ability to make precise holes.

| EDM Technique | Key Features | Common Applications |

|---|---|---|

| Wire EDM | – Utilizes a thin wire electrode to erode the workpiece – Excels at producing intricate 2D and 3D shapes – Offers exceptional cutting accuracy |

– Fabrication of tools, dies, and precision components – Industries: Aerospace, Automotive, Electronics |

| Sinker EDM | – Uses a shaped electrode to create complex cavities and profiles – Ideal for manufacturing intricate molds, dies, and complex parts – Capable of machining hard, conductive materials |

– Automotive, Aerospace, Medical device manufacturing |

| Hole Drilling EDM | – Specializes in creating small, deep holes in difficult-to-machine materials – Utilizes a tubular electrode to erode the workpiece – Enables the production of precision holes with high depth-to-diameter ratios |

– Aerospace, Automotive, Electronics (e.g., fuel injectors, cooling systems, electronic packaging) |

Each EDM technique has its own strengths. This lets manufacturers choose the best method for their needs. Whether it’s Wire EDM’s precision, Sinker EDM’s complexity, or Hole Drilling EDM’s depth, EDM techniques help industries create amazing components.

Applications of EDM

Electrical Discharge Machining (EDM) is key in many industries. It’s great for making precise cuts in hard metals. This method is perfect for creating complex shapes, helping manufacturers achieve new heights.

Precision Machining for Hard Metals

EDM is top-notch for machining hard metals like tungsten carbide and titanium. These are used in places where strength matters a lot, like in the aerospace industry and medical industry. It’s great because it doesn’t wear out tools, making precise parts possible.

Common Uses in Aerospace and Medical Industries

The aerospace industry loves EDM for making important parts. It’s used for turbine blades, engine nozzles, and more. EDM’s precision is key for these high-stakes jobs.

The medical industry also benefits from EDM. It’s used for making orthopedic implants and surgical tools. The ability to make complex shapes and keep tight tolerances is vital for safety and performance.

| Industry | EDM Applications |

|---|---|

| Aerospace |

|

| Medical |

|

As innovation grows, EDM’s role becomes even more crucial. It’s a vital tool for creating advanced products and solutions.

Benefits and Limitations of EDM

Electrical Discharge Machining (EDM) is a precise and versatile method for making things. It has its own set of benefits and challenges. Knowing these is key for those looking to improve their making processes.

Advantages: Precision and Material Hardness

EDM is great at making things with precision. It can create complex shapes with high accuracy. This makes it perfect for industries like aerospace and medical devices.

It also does well with machining hard materials. This includes super-alloys, ceramics, and carbides. These are hard to work with using regular methods.

Challenges: Speed and Setup Costs

EDM is not without its drawbacks. It’s slower than traditional methods, affecting how fast things get made. Also, setting it up can be expensive. This is because it needs special tools and fluids.

Still, EDM is very useful for certain tasks. It’s great for things that need to be made with high accuracy and surface quality. Knowing its strengths and weaknesses helps manufacturers use it wisely.

“EDM’s precision and versatility make it an invaluable asset in high-precision manufacturing, but its limitations in speed and setup costs must be carefully weighed to ensure optimal efficiency.”

Shixinproto’s EDM Services

At Shixinproto, we’re proud to offer top-notch Electrical Discharge Machining (EDM) services. Our team of experts uses the latest technology to create precise parts for many fields. These include aerospace, automotive, and medical.

Need complex designs, special materials, or exact fits? Our EDM services are designed to fit your specific needs. We use wire EDM for fine cuts and sinker EDM for detailed cavities. Our advanced methods guarantee top-notch results every time.

We aim to be your reliable partner in success at Shixinproto. Our focus on quality, innovation, and customer happiness makes us stand out. We’re the first choice for those needing expert EDM solutions for tough projects.