In the world of modern manufacturing and personalization, laser marking has become an indispensable tool, offering precise and efficient methods of surface modification. Two of the most prominent laser marking techniques are laser etching and laser engraving, each with its own unique characteristics and applications. Understanding the nuances between these two processes can be crucial in selecting the right approach for your project.

Laser etching and laser engraving both utilize the power of focused laser beams to create intricate designs, logos, or identification marks on a variety of materials. However, the underlying mechanisms and the resulting effects differ significantly, making each technique suitable for specific needs and challenges.

What is Laser Etching?

Laser etching is a surface marking technique that uses focused laser beams to alter the surface of a material, resulting in a shallow, permanent mark. This process relies on heat-induced oxidation to create the desired design or pattern on the surface, without removing significant material. Laser etching is particularly well-suited for applications where a surface marking is required without compromising the structural integrity of the underlying material.

The Process of Laser Etching

The laser etching process involves directing a high-energy laser beam onto the surface of the target material. The laser’s heat causes local oxidation or discoloration of the material, creating the desired mark or pattern. Unlike laser engraving, which involves material removal, laser etching simply alters the surface through a heat-induced chemical reaction, leaving the underlying structure largely intact.

Materials Suitable for Laser Etching

- Metals (e.g., stainless steel, aluminum, titanium)

- Plastics (e.g., acrylic, polycarbonate, ABS)

- Ceramics

- Glass

Key Features of Laser Etching

- Shallow Depth: Laser etching creates a surface mark with a shallow depth, typically ranging from a few microns to a few hundred microns, depending on the material and laser parameters.

- Precision: Laser etching offers excellent precision, allowing for the creation of intricate designs and patterns with high levels of detail.

- Permanence: The laser-etched marks are highly durable and resistant to wear, making them suitable for a wide range of applications, including product identification, serial numbers, and branding.

- Flexibility: Laser etching can be easily integrated into automated production processes, enabling efficient and cost-effective marking solutions.

“Laser etching is a versatile and precise technique that allows us to create durable surface markings without compromising the underlying material’s structure.”

What is Laser Engraving?

Laser engraving is a powerful technique that utilizes high-power lasers to permanently mark or etch designs, text, or images onto various materials. Unlike laser etching, which creates shallow surface modifications, laser engraving involves the removal of material to create deeper, more prominent markings. This process is particularly well-suited for applications requiring durable, long-lasting, and visually striking markings.

The Process of Laser Engraving

The laser engraving process works by directing a tightly focused, high-intensity laser beam onto the surface of the material. The laser beam’s energy is absorbed by the material, causing it to vaporize and remove tiny amounts of the surface. By precisely controlling the laser’s power, pulse duration, and beam movement, intricate designs and patterns can be engraved onto the material.

Materials Suitable for Laser Engraving

- Metals (e.g., stainless steel, aluminum, titanium)

- Plastics (e.g., acrylic, polycarbonate, ABS)

- Wood and wooden products

- Leather and textiles

- Ceramic and glass

Key Features of Laser Engraving

Laser engraving offers several distinctive features that make it a versatile and efficient marking technique:

- Deep Marking: The removal of material creates deeper, more prominent markings that are less susceptible to wear and tear over time.

- High-Resolution Designs: Laser engraving can produce intricate, high-resolution designs and text with exceptional detail and precision.

- Material Versatility: Laser engraving can be applied to a wide range of materials, including metals, plastics, wood, and more.

- Automation and Efficiency: Laser engraving can be easily integrated into automated production processes, making it a highly efficient marking solution.

The combination of deep marking, material versatility, and high-resolution capabilities make laser engraving a popular choice for a variety of applications, from product identification and customization to industrial marking and branding.

Key Differences Between Laser Etching and Laser Engraving

When it comes to permanent markings, laser etching and laser engraving are two distinct techniques that offer unique advantages. Understanding the comparison between these methods is crucial in choosing the right approach for your application suitability.

Depth of Marking: Surface vs. Deeper Cuts

The primary distinction lies in the marking depth achieved by each technique. Laser etching typically results in a shallower, surface-level marking, whereas laser engraving produces deeper, more intricate cuts into the material.

Material Interaction: Vaporization vs. Melting

The way the laser interacts with the material also differs. Laser etching works by vaporizing the surface, leaving a subtle, uniform mark. Laser engraving, on the other hand, utilizes a higher-powered laser that melts and removes material, creating a more pronounced, three-dimensional effect.

Applications and Use Cases: Where Each Technique Excels

- Laser etching is well-suited for delicate markings, such as on electronics, medical devices, and jewelry, where a discreet, uniform appearance is desired.

- Laser engraving shines in applications that require high-contrast, durable markings, like on tools, machinery, and promotional items.

Durability: Laser Etching vs. Engraving

Due to the depth of the marking, laser engraving generally offers greater durability and resistance to wear and tear compared to laser etching. However, laser etching can still provide a long-lasting, legible mark in many applications.

“Understanding the comparison between laser etching and laser engraving is essential in selecting the right technique for your specific needs.”

Choosing Between Laser Etching and Laser Engraving for Your Project

When it comes to permanent marking solutions, the choice between laser etching and laser engraving can significantly impact the success of your project. Key factors to consider include the material properties, desired durability, and the level of detail required.

Material Considerations

The material you’re working with is a crucial factor in deciding between laser etching and laser engraving. Laser etching works best on materials like stainless steel, titanium, and anodized aluminum, where the laser interacts with the surface to create a contrasting mark. Laser engraving, on the other hand, is better suited for materials like wood, leather, and plastic, where the laser actually removes material to create a deeper, more pronounced mark.

Durability and Longevity

If your project requires a highly durable and long-lasting mark, laser engraving may be the better choice. The process creates a deeper, more permanent mark that is less susceptible to wear and tear over time. Laser etching, while still very durable, produces a shallower mark that may be more susceptible to gradual fading or removal.

Detailed Design Needs

The level of detail required in your project can also influence the decision between laser etching and laser engraving. Laser engraving typically allows for more intricate and complex designs, with the ability to create fine lines, small text, and detailed graphics. Laser etching, while capable of producing high-quality marks, may be better suited for simpler, more minimalistic designs.

Ultimately, the choice between laser etching and laser engraving depends on the project requirements, material properties, and the desired level of detail and durability. By carefully considering these factors, you can make an informed decision that ensures the success of your project.

| Laser Etching | Laser Engraving |

|---|---|

| Best for stainless steel, titanium, anodized aluminum | Best for wood, leather, plastic |

| Shallower mark, more susceptible to gradual fading | Deeper, more permanent mark, less susceptible to wear and tear |

| Suitable for simpler, more minimalistic designs | Allows for more intricate and complex designs, fine lines, small text, and detailed graphics |

Shixinproto’s Laser Marking Services

At Shixinproto, we pride ourselves on offering top-notch custom laser marking solutions to businesses across a wide range of industrial applications. Our team of experienced professionals is dedicated to delivering personalized laser etching and laser engraving services that cater to the unique needs of our clients.

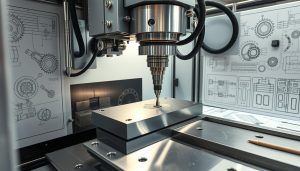

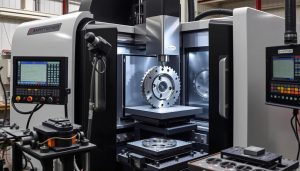

Professional Laser Etching and Engraving Solutions for Your Business

Whether you’re looking to add a unique touch to your products, create durable serial numbers, or enhance your brand’s personalization services, Shixinproto has the expertise and state-of-the-art equipment to bring your vision to life. Our advanced laser marking technology ensures precise, high-quality results that stand the test of time.

From metal and plastic to glass and wood, our team can work with a wide range of materials to deliver exceptional custom laser marking solutions tailored to your specific requirements. With a focus on quality and attention to detail, we strive to exceed your expectations and help your business stand out in the marketplace.