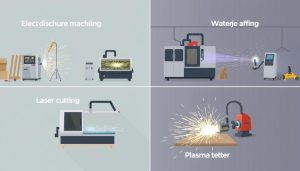

In the world of precision manufacturing, two cutting-edge techniques have emerged as industry leaders: laser cutting and wire electrical discharge machining (wire EDM). As manufacturers strive to produce intricate, high-quality parts, the choice between these two methods has become a critical decision. This article will explore the advantages and applications of laser cutting and wire EDM, helping you determine the best approach for your specific project requirements..

What is Laser Cutting?

Laser cutting is a versatile and highly precise manufacturing process that utilizes a focused beam of light to cut, engrave, or etch a wide range of materials. This technology has revolutionized the way industries approach cutting and shaping components, thanks to its remarkable speed, accuracy, and efficiency.

Overview of the Laser Cutting Process

The laser cutting process involves directing a high-energy laser beam onto the target material, which is typically metal, plastic, or wood. The laser beam heats the material to the point of melting or vaporization, allowing the material to be cut with exceptional precision and detail. The process is controlled by computer-aided design (CAD) software, which guides the laser’s movement and ensures a clean, accurate cut every time.

Benefits of Laser Cutting: Speed and Precision

One of the primary benefits of laser cutting is its remarkable speed and precision. Laser cutting machines can achieve cutting speeds of up to 20 meters per minute, making it an incredibly efficient method for high-volume production. Additionally, the laser’s ability to create intricate designs and patterns with micron-level accuracy makes it an ideal choice for applications that require tight tolerances and complex geometries.

Materials Best Suited for Laser Cutting

The versatility of laser cutting extends to the wide range of materials it can accommodate, including:

- Metals (such as steel, aluminum, and stainless steel)

- Plastics (including acrylic, polycarbonate, and PVC)

- Wood and wood-based materials (like plywood and MDF)

- Ceramics and glass

- Textiles and fabrics

The ability to precisely cut these diverse materials makes laser cutting an invaluable tool in industries ranging from manufacturing and construction to art and design.

“Laser cutting is a game-changer in the world of precision manufacturing, offering unparalleled speed, accuracy, and versatility across a wide range of materials.”

What is Wire EDM?

Wire EDM, or Wire Electrical Discharge Machining, is a highly precise manufacturing process that utilizes a thin wire to cut through tough and conductive materials. Unlike traditional cutting methods, wire EDM doesn’t rely on physical contact, making it an ideal choice for intricate and complex designs.

Overview of Wire EDM Process

The wire EDM process works by passing an electrical current through a thin wire, typically made of brass or tungsten, that is submerged in a dielectric fluid. This creates a controlled electrical discharge between the wire and the workpiece, eroding the material with extraordinary precision. The wire is continuously fed through the workpiece, allowing for the creation of highly intricate shapes and patterns.

Advantages of Wire EDM: Tighter Tolerances and Thick Materials

One of the primary advantages of the wire EDM process is its ability to achieve tighter tolerances compared to other cutting methods. The non-contact nature of wire EDM allows for extremely precise cuts, with tolerances as tight as ±0.0025 mm (±0.0001 inches). Additionally, wire EDM can effectively cut through thick materials, making it a valuable tool for industries that require the processing of heavy-duty components.

Types of Materials Suitable for Wire EDM

- Hardened tool steels

- Titanium alloys

- Inconel

- Tungsten carbide

- Ceramics

- Conductive composites

The versatility of wire EDM allows it to process a wide range of conductive materials, from tough metals to advanced ceramics and composites. This makes it a valuable tool for industries such as aerospace, automotive, and medical device manufacturing, where precision and the ability to work with challenging materials are crucial.

Key Differences Between Laser Cutting and Wire EDM

When it comes to precision manufacturing, laser cutting and wire EDM (Electrical Discharge Machining) are two of the most widely used techniques. While both offer distinct advantages, understanding the key differences can help you make an informed decision for your specific project requirements.

Cutting Speed: Which is Faster?

Generally, laser cutting has the edge in terms of cutting speed. The high-energy laser beam can quickly slice through materials, making it an efficient choice for high-volume production. In contrast, wire EDM relies on a slower, more controlled process of eroding the material, which can take longer for intricate cuts or thicker workpieces.

Precision and Tolerances: Comparing the Methods

When it comes to precision and tight tolerances, wire EDM emerges as the superior option. The wire-based process can achieve tighter dimensional accuracy and better surface finishes compared to laser cutting. This makes wire EDM well-suited for applications requiring extremely precise components, such as in the aerospace, medical, and electronics industries.

Material Thickness: Which Method Handles Thick Materials Better?

While laser cutting excels at cutting thin to moderately thick materials, wire EDM shines when it comes to processing thicker workpieces. The wire-based approach can effectively cut through materials up to several inches thick, making it the preferred choice for working with bulkier parts or components.

The choice between laser cutting and wire EDM ultimately depends on the specific requirements of your project, such as the desired cutting speed, precision needs, and material thickness. By understanding these key differences, you can make an informed decision that aligns with your manufacturing goals and delivers the best results.

Applications: Laser Cutting vs Wire EDM

When it comes to manufacturing and fabrication, laser cutting and wire EDM (Electrical Discharge Machining) are two distinct techniques, each with its own set of applications and advantages. Understanding the specific use cases for these methods can help you determine the best approach for your project.

Best Applications for Laser Cutting

Laser cutting excels in applications where speed, precision, and intricate detail work are paramount. This technology shines in the following industries:

- Automotive – Laser cutting is commonly used to fabricate complex automotive parts, such as intricate body panels, grilles, and brackets, with exceptional accuracy and efficiency.

- Aerospace – The aerospace industry relies on laser cutting to produce lightweight, high-precision components for aircraft and spacecraft, ensuring safety and performance.

- Electronics – Laser cutting is ideal for cutting printed circuit boards, thin metal components, and other delicate electronic parts with exceptional precision.

- Signage and Art – Laser cutting excels at creating intricate designs, patterns, and text for signage, sculptures, and other artistic applications.

Best Applications for Wire EDM

Wire EDM, on the other hand, is particularly well-suited for applications that require tight tolerances and the ability to work with thick, hard materials. This technology is frequently used in the following industries:

- Tool and Die Making – Wire EDM is invaluable for creating complex molds, dies, and tools with exceptional precision and surface finish, even for hard materials like tool steel and titanium.

- Automotive and Aerospace – In addition to laser cutting, these industries also utilize wire EDM for producing tight-tolerance components, such as engine parts, turbine blades, and other critical hardware.

- Medical Device Manufacturing – The medical industry relies on wire EDM to fabricate intricate, high-precision components for surgical instruments, implants, and other specialized medical devices.

By understanding the unique strengths of laser cutting and wire EDM, manufacturers can make informed decisions about the best technology for their specific project requirements, ensuring optimal results and cost-effectiveness.

Cost Comparison: Laser Cutting vs Wire EDM

When it comes to manufacturing, cost-effectiveness is a crucial factor. Laser cutting and wire EDM (Electrical Discharge Machining) are two popular metal-cutting techniques, but their costs can vary significantly. Let’s explore the equipment, setup, and operational expenses associated with each method to determine the more cost-effective option.

Equipment and Setup Costs

Laser cutting equipment typically requires a higher initial investment compared to wire EDM. The laser cutting machine itself, along with the necessary safety features and support systems, can be quite expensive. In contrast, wire EDM setups are generally more budget-friendly, with the machine and supporting components costing less.

However, the setup costs for wire EDM can be higher due to the complex programming and precision required to configure the system. Laser cutting, on the other hand, often has a more straightforward setup process, which can be a significant advantage for businesses with limited technical expertise or resources.

Operational Costs: Which Method is More Cost-Effective?

When it comes to ongoing operational costs, the picture becomes more nuanced. Laser cutting is generally more energy-efficient, consuming less power than wire EDM during the cutting process. This can lead to lower utility bills and a more cost-effective manufacturing process in the long run.

Moreover, laser cutting can often achieve faster cutting speeds, which can translate into higher productivity and cost savings. Wire EDM, on the other hand, may require more extensive maintenance and consumable parts, such as wire and dielectric fluid, adding to the operational expenses.

| Cost Factor | Laser Cutting | Wire EDM |

|---|---|---|

| Equipment and Setup Costs | Higher | Lower |

| Operational Costs | Lower | Higher |

| Overall Cost-Effectiveness | Potentially more cost-effective in the long run | Potentially less cost-effective in the long run |

Ultimately, the decision between laser cutting and wire EDM should be based on the specific requirements of your project, including factors such as material thickness, precision needs, and production volume. By carefully weighing the cost considerations, you can make an informed choice that maximizes manufacturing cost-effectiveness for your business.

Shixinproto laser cutting and wire cutting services tailored to your needs

At Shixinproto, we understand that every manufacturing project has unique requirements. That’s why we offer specialized laser cutting and wire EDM services designed to meet your specific needs. Our team of experts is dedicated to providing customized solutions that maximize efficiency, precision, and cost-effectiveness for your business.

Whether you’re working with intricate designs, thick materials, or tight tolerances, Shixinproto has the expertise and equipment to deliver exceptional results. Our state-of-the-art laser cutting technology and advanced wire EDM capabilities allow us to tackle a wide range of manufacturing challenges, from rapid prototyping to high-volume production.

Shixinproto’s commitment to innovation and customer satisfaction is at the heart of everything we do. We work closely with our clients to understand their goals, preferences, and constraints, then tailor our services to ensure a perfect fit. With Shixinproto, you can trust that your Shixinproto services, custom laser cutting, and wire EDM solutions will exceed your expectations and drive your business forward.