In the realm of modern manufacturing, CNC (Computer Numerical Control) milling has emerged as a game-changing technology that revolutionizes the way we create complex and precise parts. This advanced machining process utilizes computer-controlled machines to remove material from a workpiece with unparalleled accuracy and efficiency, making it an indispensable tool in a wide range of industries.

At the heart of CNC milling is the seamless integration of computer software and mechanical hardware, allowing for the precise control of cutting tools and the creation of intricate designs. This computer-controlled machining process enables manufacturers to produce parts with unprecedented levels of precision, repeatability, and consistency, making it a crucial component in the manufacturing landscape.

Whether you’re in the aerospace, automotive, or electronics sectors, CNC milling offers a versatile and cost-effective solution for your manufacturing needs. From prototyping to full-scale production, this technology empowers businesses to push the boundaries of what’s possible, delivering high-quality results that meet the most demanding specifications.

Key Takeaways

- CNC milling is a computer-controlled machining process that removes material from a workpiece with high precision and accuracy.

- The integration of computer software and mechanical hardware enables the creation of complex and intricate designs.

- CNC milling offers versatility, cost-effectiveness, and efficiency in a wide range of manufacturing industries.

- This technology is essential for precision manufacturing, prototyping, and product development.

- CNC milling allows for consistent, repeatable, and high-quality results that meet the most demanding specifications.

Understanding CNC Milling

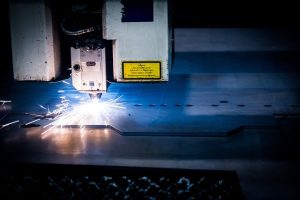

Computer Numerical Control (CNC) has revolutionized the manufacturing industry, transforming the way milling processes are executed. CNC milling is a highly automated and precise technique that utilizes computer-controlled machinery to shape and sculpt various materials with unparalleled accuracy.

What Is CNC Milling?

CNC milling is a subtractive manufacturing process that removes material from a workpiece to create the desired shape or form. This process is guided by a computer program that precisely controls the movement and actions of the cutting tools, ensuring consistent and repeatable results.

The Role of Computer Numerical Control (CNC) in Milling

The integration of computer numerical control (CNC) technology into the milling process has drastically improved efficiency, precision, and productivity. CNC milling machines are programmed to follow a predetermined set of instructions, allowing for the creation of complex, intricate parts with a high degree of accuracy.

Types of CNC Milling Machines

- Vertical CNC Milling Machines: These machines feature a vertically oriented spindle and are commonly used for drilling, pocketing, and other 2.5D operations.

- Horizontal CNC Milling Machines: With a horizontally positioned spindle, these machines are well-suited for larger workpieces and offer increased versatility in milling operations.

- Multi-Axis CNC Milling Machines: Advanced machines with three or more axes of movement, enabling the creation of complex, freeform shapes and geometries.

Each type of CNC milling machine is designed to handle specific manufacturing requirements, catering to the diverse needs of industries such as computer numerical control, CNC milling machines, and automated manufacturing.

By leveraging the power of computer numerical control, manufacturers can achieve unprecedented levels of computer numerical control, CNC milling machines, and automated manufacturing, revolutionizing the way products are designed, prototyped, and produced.

The CNC Milling Process

CNC milling is a sophisticated manufacturing process that transforms digital designs into physical products with remarkable precision and efficiency. Let’s dive into the key steps involved in this captivating journey.

Steps Involved in CNC Milling

- CAD Design: The process begins with the creation of a detailed computer-aided design (CAD) model, which serves as the blueprint for the final product.

- CNC Programming: The CAD model is then converted into a CNC program, which provides the precise instructions for the milling machine to follow.

- Workpiece Preparation: The raw material, known as the workpiece, is carefully secured in the milling machine to ensure stability and precision during the milling process.

- Milling Operation: The CNC milling machine follows the programmed instructions, using a variety of CNC milling tools to remove material from the workpiece, shaping it into the desired form.

- Quality Inspection: Once the milling process is complete, the final product undergoes a thorough quality inspection to ensure it meets the required specifications.

Tools and Equipment Used in CNC Milling

CNC milling relies on a range of specialized tools and equipment to achieve the desired results. Some of the key components include:

- End mills: These cutting tools are used to create various shapes and profiles on the workpiece.

- Face mills: Designed for removing material from the top surface of the workpiece, face mills ensure a smooth and consistent finish.

- Drill bits: Crucial for creating precise holes and openings in the workpiece.

- Coolant systems: Maintain the temperature of the milling tools and workpiece, ensuring optimal performance and prolonging the life of the equipment.

Materials That Can Be Processed Using CNC Milling

CNC milling is a highly versatile process, capable of shaping a wide range of workpiece materials, including:

- Metals: Aluminum, stainless steel, titanium, and more.

- Plastics: Acrylic, polycarbonate, and various engineering polymers.

- Composites: Carbon fiber, fiberglass, and advanced composite materials.

The choice of material depends on the specific application, performance requirements, and the desired characteristics of the final product.

Benefits of CNC Milling

CNC milling is a versatile manufacturing process that offers numerous benefits for precision-driven industries. From its high accuracy and repeatability to its cost-effectiveness and efficiency, this technology continues to revolutionize the way complex parts and components are produced.

High Precision and Accuracy

One of the primary advantages of CNC milling is its ability to deliver precision manufacturing with unparalleled accuracy. The computer-controlled nature of the machines allows for tight tolerances, ensuring that every part produced meets the strictest specifications. This level of precision is crucial in industries such as aerospace, medical, and automotive, where even the slightest variation can have significant consequences.

Versatility in Manufacturing

CNC milling machines are capable of handling a wide range of versatile production tasks, from simple to highly complex geometries. This versatility allows manufacturers to adapt to changing market demands and create a diverse array of products using a single machine. Whether it’s intricate prototypes or large-scale production runs, CNC milling provides the flexibility to meet the needs of various industries and applications.

Cost-Effectiveness and Efficiency

The efficient machining capabilities of CNC milling contribute to its cost-effectiveness. Automated processes, reduced material waste, and the ability to streamline production workflows all lead to significant cost savings for manufacturers. Additionally, the consistent quality and repeatability of CNC milling help minimize costly rework or scrap, further enhancing the overall cost-efficiency of the process.

By leveraging the benefits of precision, versatility, and efficiency, CNC milling has become an invaluable tool for a wide range of industries, enabling them to push the boundaries of what is possible in modern manufacturing.

Applications of CNC Milling

CNC milling has become an indispensable tool in various industries, showcasing its versatility and precision. From the intricate aerospace components to the sleek automotive parts, this advanced manufacturing technique has found its way into an array of applications, transforming the way products are created.

Aerospace and Automotive Industries

The aerospace and automotive sectors are prime examples of industries that heavily rely on CNC milling. In the aerospace domain, CNC milling is used to fabricate complex, high-precision parts for aircraft, satellites, and other aerospace components. The ability to produce tight tolerances and intricate geometries is crucial in this industry, where safety and performance are of utmost importance.

Similarly, the automotive industry leverages CNC milling to manufacture a wide range of automotive parts, from engine blocks and transmission components to body panels and trim pieces. The speed, accuracy, and repeatability of CNC milling make it an indispensable tool for producing the high-quality parts that modern vehicles demand.

Prototyping and Product Development

CNC milling also plays a pivotal role in the world of rapid prototyping and product development. By allowing for the quick and cost-effective creation of physical models and prototypes, CNC milling enables designers, engineers, and manufacturers to iterate and refine their ideas more efficiently. This streamlined process accelerates the path from concept to final product, ultimately leading to faster time-to-market and increased innovation.

Electronics and Consumer Products

Beyond the aerospace and automotive realms, CNC milling finds applications in the manufacturing of electronic devices and consumer products. From precision-machined components for smartphones and laptops to intricate housings for household appliances, CNC milling provides the necessary accuracy and versatility to meet the evolving demands of these industries.

The versatility of CNC milling is a testament to its growing importance in the modern manufacturing landscape. As industries continue to seek innovative solutions for their production needs, the role of CNC milling will undoubtedly continue to expand, shaping the future of aerospace, automotive, electronics, and beyond.

| Industry | Applications of CNC Milling |

|---|---|

| Aerospace | Aircraft parts, satellite components, aerospace electronics |

| Automotive | Engine blocks, transmission parts, body panels, trim pieces |

| Electronics | Smartphone and laptop components, appliance housings |

| Consumer Products | Household appliances, furniture, sporting goods |

“CNC milling has revolutionized the way we approach manufacturing, allowing us to create complex, high-precision parts that were once unimaginable.”

The versatility and precision of CNC milling have made it an indispensable tool across a wide range of industries, from the aerospace components and automotive parts to the realm of rapid prototyping. As technology continues to evolve, the applications of CNC milling will only continue to expand, shaping the future of modern manufacturing.

Why Choose Shixinproto for CNC Milling Services

When it comes to custom CNC milling solutions, Shixinproto stands out as a trusted partner. With their expertise in handling complex projects, the team at Shixinproto delivers exceptional results that exceed expectations. From aerospace to automotive, they have the capability to work with a diverse range of materials and cater to various industries.

Expert CNC Milling Solutions for Complex Projects

Shixinproto’s team of skilled engineers and technicians are well-versed in the latest CNC milling techniques. They have the knowledge and experience to tackle even the most intricate projects, ensuring precision, accuracy, and quality every step of the way. Whether you need custom parts or prototypes, Shixinproto has the expertise to bring your vision to life.

Customized CNC Milling for Diverse Materials and Industries

At Shixinproto, they understand that no two projects are the same. That’s why they offer a wide range of custom CNC milling services tailored to your specific needs. From rapid manufacturing to high-quality machined parts, they have the capabilities to work with a vast array of materials, catering to the unique requirements of various industries.

Fast Turnaround and High-Quality Results

Time is of the essence in today’s fast-paced world, and Shixinproto recognizes that. With their commitment to efficient processes and state-of-the-art equipment, they ensure a fast turnaround without compromising on quality. Whether you need a quick prototype or a batch of precision-engineered components, Shixinproto delivers high-quality results that exceed your expectations.