Heat sinks are key in managing heat from electronic devices. The materials used in them are vital for efficient heat dissipation. The right materials can greatly improve a device’s performance and lifespan.

Heat sink materials help absorb and spread out heat. This prevents overheating and damage to sensitive parts.

Knowing about different heat sink materials is important for managing heat well. Each material has its own benefits. Choosing the right one depends on the device’s needs.

By looking into the main materials for heat sinks, we see how important managing heat is. We also understand the role of these materials in keeping devices running smoothly.

Understanding Heat Sink Fundamentals

Heat sinks are key in managing heat, and knowing how they work is vital. Thermal management principles say heat sinks should have lots of surface area. This helps in transferring heat well from the source to the air around it. The design and materials used in heat sinks greatly affect how well they work.

The main job of a heat sink is to take in and spread out heat from electronic parts. By using thermal management principles, engineers can make heat sinks that transfer heat better. This lowers the chance of overheating and makes systems more reliable. Important things that affect how well a heat sink works include the material it’s made of, its size, and how well air moves around it.

- Material selection: Choosing a material with high thermal conductivity, such as copper or aluminum, can enhance heat sink performance.

- Surface area: Increasing the surface area of the heat sink can improve heat dissipation, but may also increase costs and complexity.

- Airflow: Ensuring adequate airflow around the heat sink is critical for efficient heat transfer and dissipation.

Understanding heat sink fundamentals and using thermal management principles helps engineers make good heat sinks. These are needed for today’s electronic systems to work well and safely.

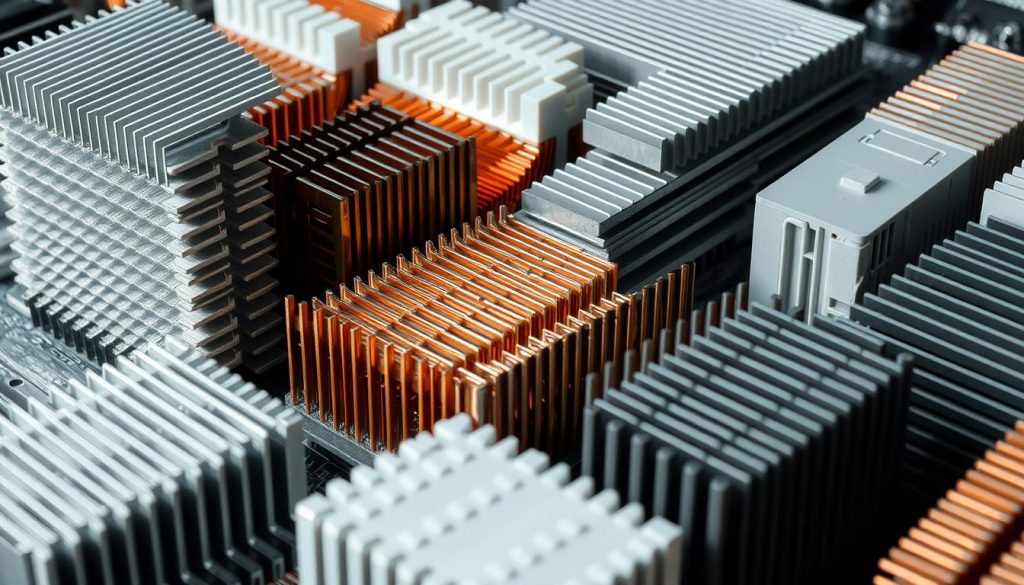

What Are Heat Sinks Made Of: Primary Materials

Heat sinks are made from important materials that affect how well they work. Aluminum heat sinks and copper heat sinks are top choices. They are picked for their great heat transfer, lasting quality, and good value.

Here are some key traits of aluminum heat sinks and copper heat sinks:

- High thermal conductivity: for efficient heat transfer

- Corrosion resistance: for a long life

- Lightweight: easy to use in many places

Aluminum heat sinks are great for gadgets like laptops and phones because they’re affordable and work well. Copper heat sinks are best for big power needs, like in servers and data centers, because they transfer heat really well.

Knowing about these materials is key to picking the right heat sink. Think about how well they transfer heat, resist corrosion, and their cost. This helps designers and engineers choose the best heat sink for their projects.

| Material | Thermal Conductivity (W/mK) | Cost |

|---|---|---|

| Aluminum | 237 | Low |

| Copper | 386 | High |

Aluminum Heat Sink Properties and Applications

Aluminum is a top choice for making heat sinks. It’s great at conducting heat and is strong. This makes aluminum alloys perfect for heat sinks, as they can spread heat well and stay strong.

Using aluminum in heat sinks has many advantages. It’s good at conducting heat, doesn’t rust easily, and is affordable. Aluminum alloys are also light, making them easy to use in many ways. In making heat sinks, aluminum alloys help create shapes that help with heat release.

Benefits of Aluminum in Heat Sinks

- High thermal conductivity: Aluminum alloys are great at moving heat away from the source.

- Corrosion resistance: They don’t rust easily, making them good for tough places.

- Affordability: Aluminum is cheaper than some other materials, like copper.

Aluminum alloys are also used in many areas, including heat sink manufacturing. They’re popular because they’re affordable and good at conducting heat. As research goes on, new aluminum alloys are being made to make heat sinks even better.

Copper as a Premium Heat Sink Material

Copper is a top choice for high-performance heat sinks because it conducts heat well and is strong. It’s great at spreading out heat, making it perfect for places where keeping cool is key. Copper heat sinks are used in many fields, like electronics, aerospace, and cars.

Using copper in heat sinks has its pluses. It transfers heat well and is strong, handling high temperatures and stress. But, copper can be pricey and might corrode. To fix these problems, makers often use copper alloys or add protective layers.

- High thermal conductivity, allowing for efficient heat transfer

- Mechanical strength, enabling it to withstand high temperatures and stresses

- Corrosion resistance, when properly coated or alloyed

Engineers often pick copper for high-performance heat sinks because of its great qualities. Knowing copper’s good and bad points helps designers make copper heat sinks that work well. This ensures they perform well and are reliable.

Advanced and Composite Heat Sink Materials

Technology keeps getting better, and so does heat management. New materials are being made to handle heat better, last longer, and cost less. Composite materials are getting a lot of attention because they mix different materials’ strengths. This makes them better and lighter for many uses.

Studies show these new materials can make electronics work better and last longer. Researchers are looking at carbon, phase change materials, and new tech. These materials are great because they conduct heat well, don’t expand much, and are strong.

- They conduct heat better

- They are stronger

- They are lighter

- They make devices more reliable and last longer

These advantages make advanced and composite materials a top choice for making high-tech devices. As research goes on, we’ll see even more cool materials and tech. This will open up new ways to manage heat and design electronics.

Conclusion: Choosing the Right Heat Sink Material

Choosing the right heat sink material is key for thermal management. Factors like material selection, thermal performance, cost, and manufacturing are important. By knowing the properties of materials like aluminum, copper, and composites, engineers can make smart choices.

Each material has its own benefits. Aluminum is cost-effective with good heat conductivity. Copper, on the other hand, has better heat dissipation but costs more. New materials like carbon and phase change materials offer fresh solutions for thermal design.

Choosing the right material is a big step in thermal management. Engineers must consider each application’s needs and weigh the options carefully. This ensures their systems work well, are reliable, and cost-effective.