In the dynamic world of metal fabrication, one process stands out as a critical component in creating durable and reliable products – tapping. This versatile technique plays a pivotal role in the manufacturing landscape, allowing engineers and fabricators to efficiently produce threaded holes essential for fastening components, ensuring precision and structural integrity.

Tapping, the process of cutting internal threads in a pre-drilled hole, is a fundamental process in modern metalworking. By mastering this technique, manufacturers can harness the power of threaded connections, unlocking a world of possibilities in a wide range of industries, from automotive to aerospace. This article delves into the key insights surrounding tapping in metal fabrication, shedding light on its significance, techniques, and applications.

What is Tapping in Metal Fabrication?

In the realm of metal fabrication, tapping is a fundamental process that plays a crucial role in creating internal threads within workpieces. This technique is essential for securing fasteners, such as bolts and screws, which are integral to the construction and assembly of various metal-based products.

Overview of the Tapping Process

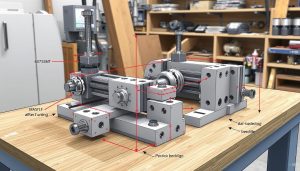

The tapping process involves using a specialized tool, known as a tap, to cut or form threads within a pre-drilled hole in a metal workpiece. Taps come in various sizes and designs to accommodate different thread types and materials, ensuring a precise and secure fit for the fasteners. The process of tapping requires skill, precision, and the use of appropriate tapping tools to achieve the desired results.

Types of Taps Used in Fabrication

- Hand Taps: These are manual taps used for small-scale or localized thread cutting operations, often in situations where access is limited or specialized equipment is unavailable.

- Machine Taps: Designed for use in power-driven tools and CNC machines, machine taps are employed for high-volume or automated internal threads production in metal fabrication settings.

- Specialized Taps: Certain applications may require the use of specialized taps, such as those designed for tapping metal threading in hard-to-reach areas or for specific materials like aluminum or stainless steel.

The selection of the appropriate tap for a given metal fabrication task is crucial to ensure the quality and integrity of the internal threads created, as well as the overall performance and reliability of the final product.

| Tap Type | Application | Material Compatibility |

|---|---|---|

| Hand Tap | Small-scale, localized thread cutting | Mild steel, aluminum, brass |

| Machine Tap | High-volume, automated internal thread production | Wider range of metals, including stainless steel |

| Specialized Tap | Tapping in hard-to-reach areas or specific materials | Varies based on tap design and application |

“Tapping is a critical skill in metal fabrication, enabling the creation of secure and precise internal threads for a wide range of fastening applications.”

Why Tapping is Important in Metalworking

Tapping is a crucial process in the world of metalworking, playing a vital role in the creation of secure fastening systems and ensuring precision in manufacturing. This technique is instrumental in enhancing the overall efficiency of production processes, making it an indispensable component of the metalworking industry.

Creating Internal Threads for Fastening

One of the primary reasons why tapping is so important in metalworking is its ability to create internal threads within metal workpieces. These threads are essential for the installation of fasteners, such as bolts and screws, which are used to securely join various components together. By tapping precisely sized and accurately threaded holes, manufacturers can ensure a strong and reliable connection between different metal parts, enhancing the structural integrity of the final product.

Precision and Efficiency in Tapping

In addition to its role in fastening, tapping also contributes to the overall precision and efficiency of metalworking processes. The accuracy of the tapped threads is crucial, as it directly impacts the performance and reliability of the final assembly. Precise tapping techniques, coupled with the use of high-quality metalworking tools and equipment, help to minimize defects and reduce the need for rework or post-processing adjustments. This, in turn, enhances the manufacturing efficiency and improves the thread accuracy of the final product.

By mastering the art of tapping, metal fabricators can unlock new levels of fastening systems and metalworking efficiency, ultimately delivering higher-quality products to their customers. The importance of tapping in the metalworking industry cannot be overstated, as it remains a critical component in the pursuit of manufacturing excellence.

Different Tapping Techniques for Various Materials

When it comes to metal fabrication, the tapping process plays a crucial role in creating internal threads for fastening components. However, the specific techniques used can vary depending on the material being worked on. Understanding the differences between cutting and forming taps, as well as the best practices for tapping common metals like mild steel and aluminum, is essential for achieving precise, efficient results.

Cutting vs. Forming Taps

Tapping techniques can be broadly categorized into two main approaches: cutting and forming. Cutting taps remove material to create the internal thread, making them well-suited for tougher metals like stainless steel. On the other hand, forming taps displace and reshape the material, causing less stress on the workpiece. This makes them an ideal choice for softer metals, such as aluminum, where thread formation is a priority.

Tapping Mild Steel, Aluminum, and Other Materials

The properties of the metal being tapped heavily influence the optimal tapping technique. For mild steel, a combination of cutting and forming taps can be used to create strong, durable threads. Aluminum, with its relatively soft and malleable nature, often benefits from forming taps that minimize material displacement and ensure accurate thread formation.

- Mild Steel: Combination of cutting and forming taps for strong, durable threads

- Aluminum: Forming taps to minimize material displacement and ensure accurate thread formation

- Other Materials: Material-specific tapping techniques may be required for optimal results

Understanding the tapping techniques and metal properties is crucial for achieving the desired thread formation and ensuring the overall quality and efficiency of the metalworking process.

“Selecting the right tapping technique for the material at hand is the key to unlocking efficient and precise metalworking.”

Applications of Tapping in Manufacturing

Tapping, a crucial metal fabrication process, finds diverse applications across various industries. From the automotive sector to aerospace fabrication and sheet metal work, this versatile technique plays a pivotal role in shaping the manufacturing landscape.

Automotive Industry

In the automotive industry, tapping is indispensable for creating internal threads in components such as engine blocks, transmission housings, and suspension parts. This precise process ensures reliable fastening and the seamless integration of essential systems. Automotive manufacturers rely on tapping to achieve the high levels of quality and durability demanded by the industry.

Aerospace and Structural Fabrication

The aerospace sector and structural fabrication industry heavily utilize tapping techniques. From aircraft fuselages and wings to spacecraft components and heavy-duty machinery, tapping is critical for establishing secure connections, enhancing structural integrity, and meeting the stringent safety requirements of these industries. Aerospace and structural fabrication rely on tapping to maintain the highest standards of precision and reliability.

Sheet Metal Work

Tapping also plays a pivotal role in sheet metal work, a cornerstone of industrial applications. Whether it’s manufacturing ventilation systems, kitchen appliances, or architectural features, tapping enables the creation of precise internal threads in sheet metal components, facilitating the attachment of fasteners and ensuring the structural integrity of the final product.

| Industry | Tapping Applications | Key Benefits |

|---|---|---|

| Automotive | Engine blocks, transmission housings, suspension parts | Reliable fastening, high-quality integration of systems |

| Aerospace and Structural Fabrication | Aircraft components, spacecraft parts, heavy machinery | Secure connections, enhanced structural integrity, safety compliance |

| Sheet Metal Work | Ventilation systems, kitchen appliances, architectural features | Precise internal threads, secure fastener attachment, structural integrity |

Tapping’s versatility and precision make it an essential process across a wide range of industrial applications, from automotive manufacturing to aerospace fabrication and sheet metal work. By enabling the creation of secure internal threads, tapping plays a crucial role in ensuring the quality, durability, and safety of a diverse array of products and structures.

Why Choose Shixinproto for Your Metal Tapping Needs?

When it comes to precision metal fabrication, Shixinproto stands out as a trusted leader. With years of expertise and a commitment to excellence, our team specializes in providing top-notch metal tapping services that cater to a wide range of industries.

At Shixinproto, we pride ourselves on our ability to deliver customized metal solutions tailored to your unique requirements. Our state-of-the-art equipment and advanced tapping techniques ensure unparalleled accuracy and efficiency, making us the go-to choice for manufacturers seeking exceptional metal fabrication services.

Whether you’re in the automotive, aerospace, or sheet metal industry, Shixinproto’s comprehensive suite of metal fabrication services can meet your needs. Our skilled technicians possess the know-how to handle a variety of materials, from mild steel to aluminum, ensuring that your project is completed to the highest standards of quality and precision.