Home » Shop » Heat Sink » Die Cast Heat Sinks » Die Casting Aluminum Heatsink Plastic Inject Molds Part

Product Description

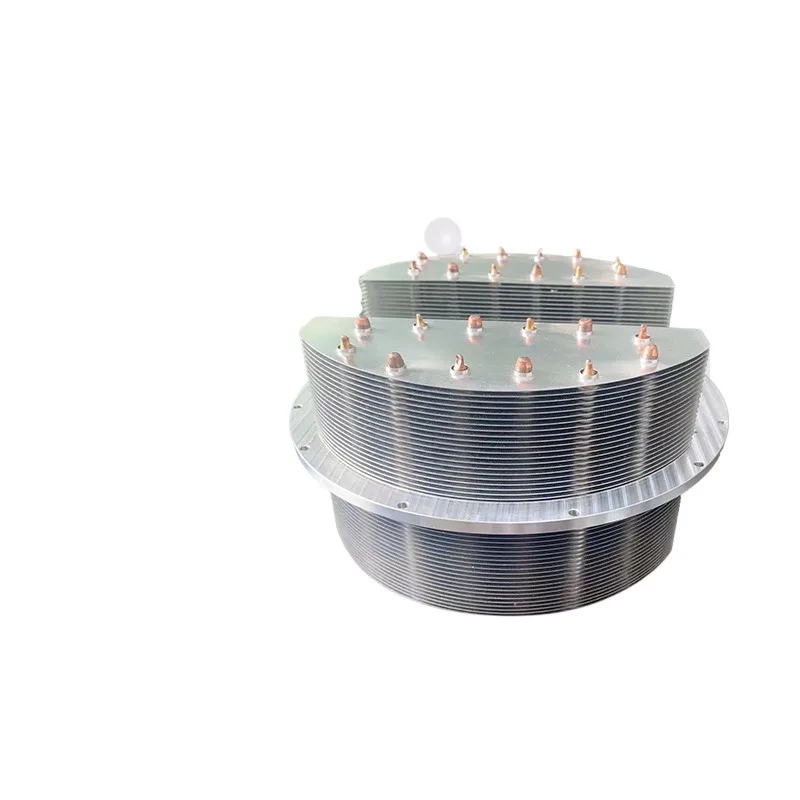

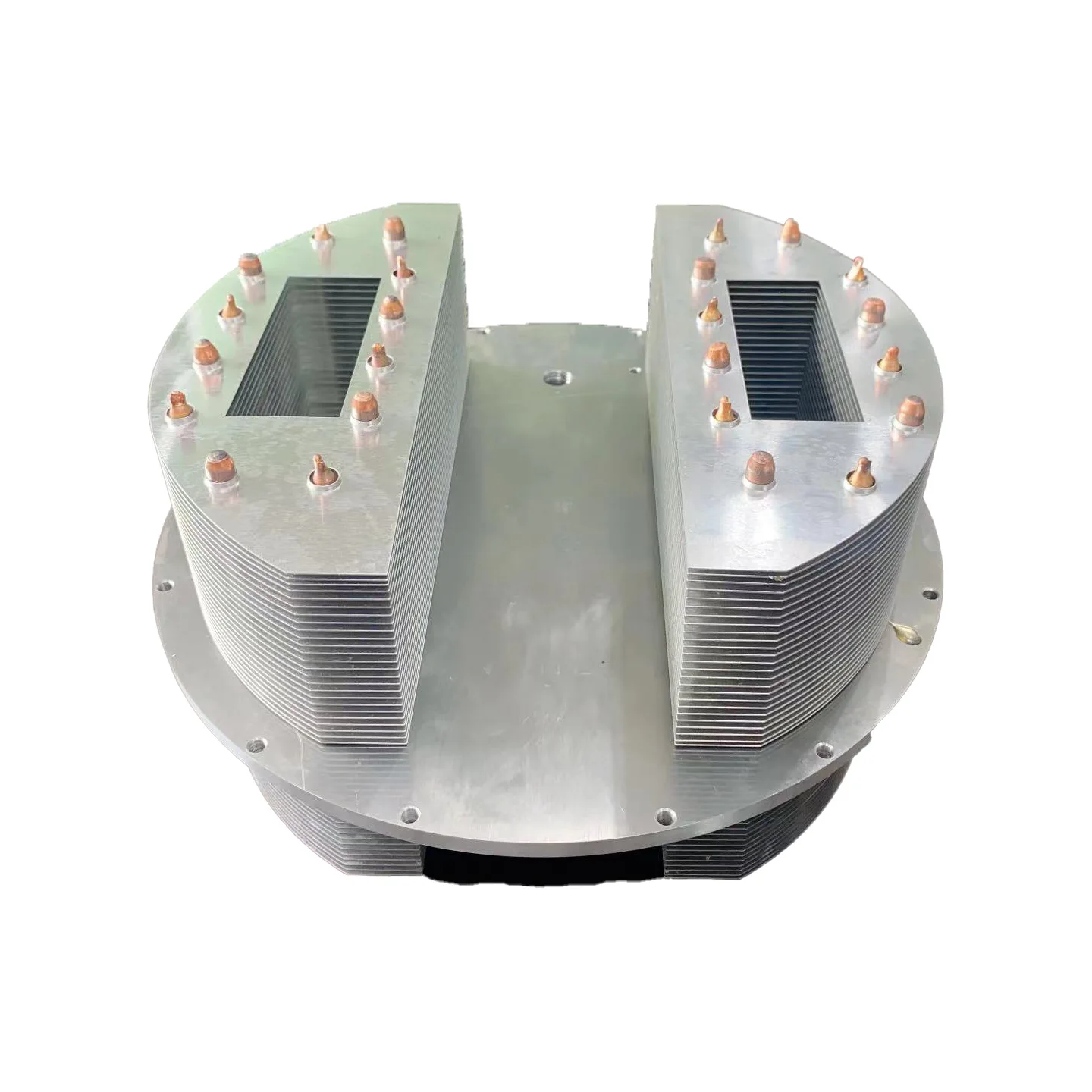

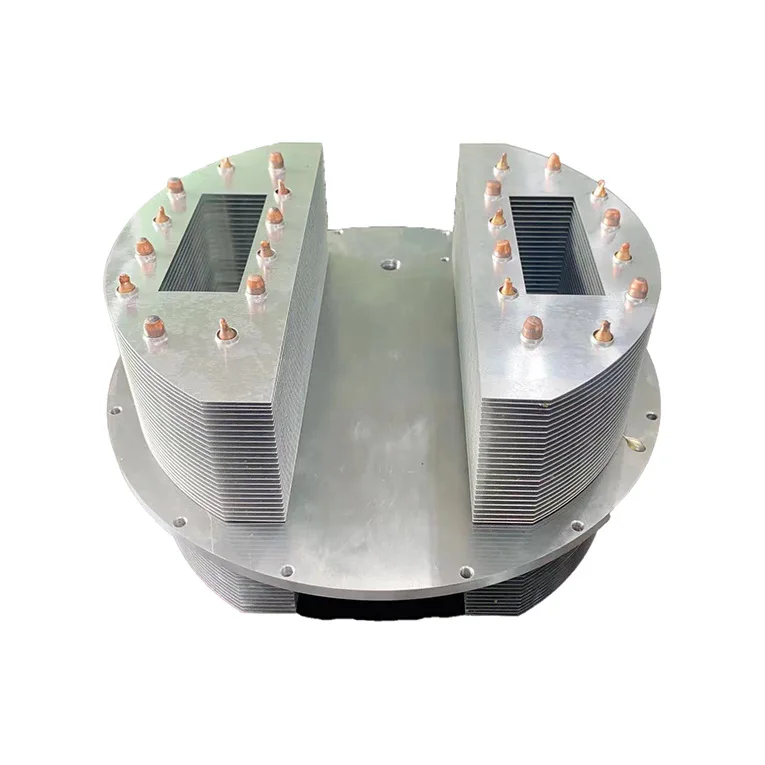

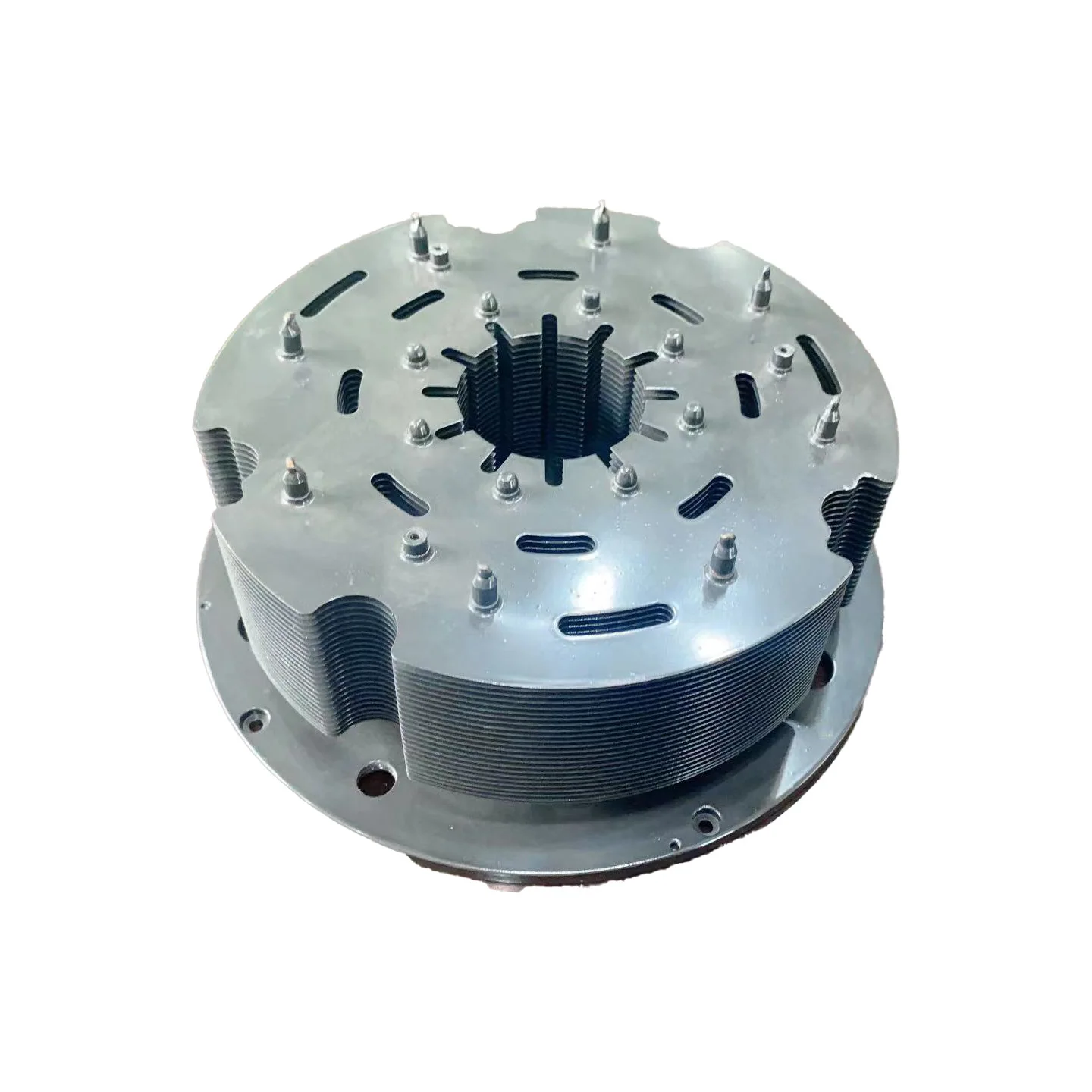

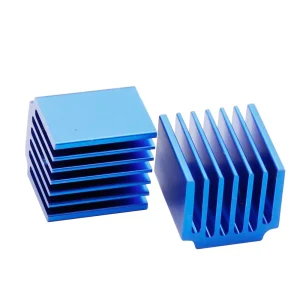

I. Die Casting Aluminum Heatsink

- Superior Material and Construction

- Shixinproto’s die casting aluminum heatsink is crafted from high-quality aluminum alloy. The die casting process ensures a seamless and durable structure, providing excellent mechanical strength to withstand various operating conditions.

- Aluminum is chosen for its outstanding thermal conductivity, which enables efficient heat dissipation. It can quickly absorb and transfer heat away from the heat source, effectively reducing the temperature of the components it is cooling.

- Efficient Heat Dissipation Design

- The heatsink features a carefully designed fin structure. These fins increase the surface area in contact with the surrounding air, facilitating enhanced heat transfer through convection. The optimized fin spacing and thickness are engineered to balance airflow resistance and heat dissipation efficiency, ensuring maximum cooling performance.

- It can be customized with different fin heights and densities according to specific heat dissipation requirements, making it suitable for a wide range of applications, from high-power electronics to industrial machinery.

II. Plastic Inject Molds Part

- Precision and Durability

- Our plastic inject molds part is manufactured with high precision. The molds are made from durable materials that can withstand the high pressures and temperatures involved in the injection molding process. This ensures consistent and accurate production of plastic parts over a long service life.

- The precision of the molds allows for the creation of complex plastic part geometries with tight tolerances. Whether it’s intricate housings or detailed connectors, the molds can reproduce the desired shapes precisely, meeting the strict quality standards of various industries.

- Versatile Application

- These plastic inject molds can be used to produce a variety of plastic parts for different industries. They are suitable for consumer electronics, automotive components, medical devices, and more. The ability to customize the molds according to specific part designs and material requirements makes them a flexible solution for plastic part manufacturing.

- The plastic parts produced from these molds can have excellent surface finishes and mechanical properties, depending on the selected plastic material and the injection molding parameters. This enables the creation of functional and aesthetically pleasing plastic components for end products.

In conclusion, Shixinproto’s die casting aluminum heatsink and plastic inject molds part offer high-quality and customizable solutions for thermal management and plastic part manufacturing. Whether you need to cool high-power electronics or produce precise plastic components, our products can meet your requirements with reliability and performance.

Related products

-

LED Light Round Heatsink Cold Forge Heat Sink High Power Extruded Aluminum CNC 9*9*5cm OEM ODM

Read more -

Aluminum Heat Sink Extruded Heatsink For Bambu Lab X1/X1C/P1P/P1S/A1/A1 mini For Creality K1/K1C/K1 MAX

Read more -

250 W LED light aluminum die casting heatsink

Read more -

3D Printer Parts A4988 DRV8825 LV8729 TMC2100 TMC2208 Stepper Motor Driver Module Heat Sinks Cooling Block Heatsink

Read more