Imagine a way to turn molten metal into precise parts quickly and accurately. Welcome to high pressure die casting (HPDC), a key method in metal production. This guide will explore HPDC’s basics, its benefits, and how it’s changing manufacturing worldwide.

What makes HPDC special? How can it help your business? Read on to find out how this process can boost your production.

What is High Pressure Die Casting?

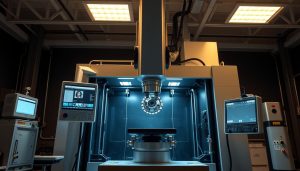

High pressure die casting, or HPDC, is a way to shape metal into complex parts. It uses high pressure to inject molten metal into a mold. This creates parts quickly and with great precision.

Overview of the HPDC Process

The process starts with making the die, a metal mold for the part. Then, molten metal is pushed into the mold at high pressure. This makes parts with detailed designs and smooth finishes.

Key Features of High Pressure Die Casting

- High production rates: HPDC makes parts fast, perfect for big orders.

- Excellent dimensional accuracy: Parts come out with precise shapes and sizes.

- Smooth surface finishes: Parts have glossy finishes, needing little extra work.

- Versatile material options: It works with many metals, like aluminum, magnesium, and zinc.

HPDC is efficient and cost-effective. It’s used in many fields, from cars and planes to gadgets and machines.

Benefits of High Pressure Die Casting

High pressure die casting (HPDC) is a cost-effective and precise method for making parts. It’s great for creating complex shapes with tight tolerances. This makes it a top choice for many industries.

High Efficiency and Low Wastage

HPDC is very efficient. It quickly makes detailed parts with little waste. This saves money by using less material and needing less work after production.

The tight tolerances in HPDC also make the process more efficient. It ensures parts are consistent and of high quality.

Excellent Surface Finish and Accuracy

HPDC is known for its excellent surface finishes and accuracy. The molds and high-pressure metal injection create parts that need little finishing. This saves time and resources.

It also makes it easy to produce complex geometries. These shapes are hard or impossible to make with other methods.

Ideal for Mass Production

HPDC is perfect for making lots of parts quickly. Its automated process and fast production speed meet the needs of big projects. It’s great for industries like cars, planes, and electronics.

“High pressure die casting is a game-changer in the world of cost-effective manufacturing, enabling the production of intricate parts with unparalleled precision and efficiency.”

Common Materials Used in High Pressure Die Casting

In high pressure die casting, the right materials are key. Aluminum, zinc, and magnesium alloys are top choices. Each has special properties and benefits.

Aluminum, Zinc, and Magnesium Alloys

Aluminum alloys are great for their strength, light weight, and resistance to corrosion. They’re perfect for cars, planes, and gadgets. Zinc alloys are known for being easy to shape and stable. They’re cost-effective for smaller parts. Magnesium alloys are strong and light, ideal for making parts that need to be both.

Choosing the Right Material for Your Project

Choosing the right material is important. You need to think about strength, weight, and cost. Knowing about alloy properties and material selection criteria helps a lot. Talking to experts in die casting can guide you to the best choice for your project.

“Selecting the right material is crucial in high pressure die casting to maximize the performance and cost-effectiveness of the final product.”

Applications of High Pressure Die Casting

High pressure die casting (HPDC) is key in many industries. It makes complex, high-performance parts. This method is used in cars, electronics, and machinery to meet today’s tech and engineering needs.

Automotive and Aerospace Components

HPDC is vital in making car and plane parts. It creates lightweight, strong engine blocks and transmission housings. The aerospace field uses it for airframe parts and engine mounts, ready for flight.

Consumer Electronics and Industrial Machinery

HPDC is also crucial for electronics and machinery. It makes phone, laptop, and tablet cases. It also makes precise parts for machinery, ensuring they work well.

| Industry | HPDC Applications |

|---|---|

| Automotive | Engine blocks, transmission housings, suspension components |

| Aerospace | Airframe parts, engine mounts, structural components |

| Consumer Electronics | Smartphone, laptop, and tablet housings |

| Industrial Machinery | Precision components for various equipment |

HPDC is vital in many fields, from cars to electronics. As tech advances, HPDC will play an even bigger role. It’s essential for making top-notch automotive parts, electronic enclosures, and precision components.

“High pressure die casting has become an essential manufacturing process, enabling the production of complex, high-performance parts that are integral to the modern world.”

Challenges in High Pressure Die Casting

High pressure die casting has many benefits but also faces unique challenges. Manufacturers must tackle addressing porosity and defects and managing material limitations and costs to keep their operations quality and cost-effective.

Addressing Porosity and Defects

Porosity and surface defects are major concerns in high pressure die casting. These issues can stem from bad mold design, temperature control problems, or metal alloy inconsistencies. To tackle these die casting defects, manufacturers need to focus on quality control measures and process optimization.

This might involve using advanced monitoring systems, improving mold filling strategies, and managing temperature and pressure during casting.

Material Limitations and Costs

High pressure die casting mainly uses aluminum, zinc, and magnesium alloys. These materials are light and strong but can be expensive. Choosing the right material for a project is crucial. It depends on part complexity, production volume, and process optimization for cost-effectiveness.

By innovating in design, enforcing quality control, and picking materials wisely, manufacturers can make the most of high pressure die casting. They can then provide high-quality, affordable products to their customers.

Shixinproto’s Die Casting Expertise

At Shixinproto, we’re known for top-notch custom die casting services. Our advanced high-pressure die casting (HPDC) tech and skilled engineers help us solve complex problems. We deliver precise solutions for any project.

High-Precision Die Casting Solutions for Complex Projects

Our HPDC tech lets us handle detailed designs and tough specs with great accuracy and speed. Our modern tools and strict quality checks mean every part meets the highest standards. This makes us the go-to for businesses needing the best die casting.

Why Shixinproto is Your Trusted Partner for Die Casting

Shixinproto is all about quality and new ideas. We’re a reliable partner for many industries. Whether it’s cars, planes, gadgets, or machines, we always go above and beyond. Trust us to make your big ideas real with our advanced HPDC and focus on quality.