In today’s fast world, getting new products to market quickly is key. Rapid prototyping is a game-changer for product development. It offers a fast way to bring ideas to life. Let’s explore how it can boost your business.

Imagine cutting down the time to test and share your product ideas. Would you try a strategy that could change how you make products? This guide will show you how to speed up your innovation and make better products faster.

What is Rapid Prototyping?

Rapid prototyping is a new way to make products. It lets teams quickly design, test, and improve new ideas. With rapid prototyping techniques, companies can make products faster, get them to market sooner, and save money.

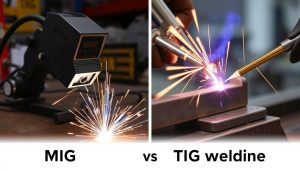

Overview of Rapid Prototyping Techniques

Rapid prototyping uses cool methods like 3D printing and CNC machining. These iterative design ways help make prototypes fast. This lets developers try out ideas and get feedback from users.

Benefits of Rapid Prototyping in Product Development

Rapid prototyping has many benefits. It helps teams find problems early, saving time and money. This approach also makes companies more innovative. They can meet market needs quickly and stay competitive.

- Accelerate time-to-market

- Reduce development costs

- Improve product quality through iterative design

- Enhance customer engagement and satisfaction

“Rapid prototyping is not just a tool, but a mindset that empowers teams to innovate faster and more effectively.”

Types of Rapid Prototyping Methods

Rapid prototyping has changed the game in product development. It offers many techniques to speed up the design process. Additive manufacturing (3D printing), CNC machining, and injection molding are key methods, each with its own strengths.

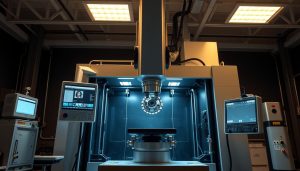

Additive Manufacturing: 3D Printing

3D printing, or additive manufacturing, has transformed prototyping. It creates complex, customized parts quickly and precisely. This method builds up layers of material, making intricate designs possible.

From concept models to functional prototypes, 3D printing is crucial. It’s a go-to tool for designers, engineers, and innovators in many fields.

CNC Machining for Prototypes

CNC machining is a vital rapid prototyping technique. It uses computer control to guide cutting tools, making accurate prototypes. CNC machining is great for parts with tight tolerances and complex geometries.

It’s perfect for small production runs and creating functional prototypes. This makes it a valuable asset in product development.

Injection Molding for Prototype Creation

Injection molding is a popular method for plastic parts. It injects molten plastic into a mold to create the desired shape. This process is known for high-quality, consistent parts with detailed features.

While often used for mass production, it’s also key for prototyping. It helps designers and engineers test their designs before full-scale production.

Each rapid prototyping method has its own benefits and drawbacks. Understanding these helps product development teams choose the best approach. This speeds up bringing innovative ideas to life.

Rapid prototypingis vital in today’s product development. It speeds up the design process, cuts down time-to-market, and boosts innovation across many industries.

| Rapid Prototyping Method | Advantages | Limitations |

|---|---|---|

| 3D Printing |

|

|

| CNC Machining |

|

|

| Injection Molding |

|

|

“Rapid prototyping is essential for product development, as it allows us to quickly validate our ideas and make informed decisions before committing to full-scale manufacturing.”

Understanding the strengths and limitations of these methods helps teams choose the best approach. This accelerates the design process, reduces time-to-market, and drives innovation in various industries.

Applications of Rapid Prototyping

Rapid prototyping is key in product development. It helps businesses in many ways. It’s great for testing products, cutting down on time, and making custom items for clients.

Testing Form, Fit, and Function

One main use of rapid prototyping is to check how a product works before making lots. It lets designers and engineers see if it fits right and works as planned. This way, they can fix any problems early on, making a better product.

Reducing Time-to-Market

In today’s fast world, getting products out quickly is important. Rapid prototyping helps companies speed up making new products. They can try out different versions, get feedback, and then launch faster. This gives them an edge over others.

Customization for Client Needs

Rapid prototyping is also great for making custom items for clients. With tech like 3D printing, companies can make special prototypes. This lets them offer unique solutions, which helps them stand out and build better relationships with customers.

| Application | Benefits |

|---|---|

| Testing Form, Fit, and Function | Identify and resolve design flaws early in the development process |

| Reducing Time-to-Market | Accelerate product development cycles and gain a competitive edge |

| Customization for Client Needs | Deliver tailored solutions that meet the unique requirements of individual clients |

Challenges and Solutions in Rapid Prototyping

Rapid prototyping has changed how we make products, but it comes with its own set of problems. The main issues are finding the right materials and balancing how fast we can make something with how well it turns out.

Material Constraints

Choosing the right materials is hard in rapid prototyping. Many methods, like 3D printing and CNC machining, can only use certain materials. This is a problem for those who need specific materials for their designs.

To solve this, experts pick the best materials for each project. They consider things like how strong the material is, how much it costs, and how long it takes to get. They also look into new materials and ways to make things, like advanced composites and hybrid methods.

Balancing Speed and Quality

Rapid prototyping aims to make product development faster. But, we can’t rush too much or the prototypes won’t be good enough. This can mess up the whole process.

Finding the right balance between speed and quality is key. This means using advanced checks, testing, and a smooth workflow. By managing these trade-offs, teams can make prototypes that are both fast and high-quality, helping products get to market quicker.

The rapid prototyping world is always changing. Overcoming these challenges will help make product development even better. By tackling material issues and balancing speed and quality, companies can use rapid prototyping to get their products to market faster and more successfully than ever.

Shixinproto’s Rapid Prototyping Services

At Shixinproto, we know how crucial quick, high-quality prototypes are for your product’s development. Our advanced technologies and expert team offer top-notch rapid prototyping services. We tailor our solutions to meet your exact needs.

Expert Solutions for High-Quality, Fast Prototypes

Our advanced manufacturing methods, like additive manufacturing and CNC machining, help us create precise prototypes. Our skilled engineers and designers ensure every prototype is of the highest quality. This lets you make informed decisions as you develop your product.

Why Choose Shixinproto for Your Prototyping Needs

Shixinproto is dedicated to outstanding service and results. Our vast experience, cutting-edge facilities, and technologies make us the perfect partner for prototyping. Trust us to create prototypes that speed up your product development and boost your success.