Have you ever thought about the differences between galvanized and galvannealed steel? These two types of steel might look the same at first, but they have unique qualities. Their manufacturing methods and uses can greatly affect your project’s success.

In this guide, we’ll dive into the main differences between galvanized and galvannealed steel. We’ll look at their strengths, weaknesses, and best uses. Knowing these details can help you make better choices for your projects, whether in construction or product design.

What is Galvanized Steel?

Galvanized steel is a type of steel coated with zinc through hot-dip galvanizing. This zinc layer offers top-notch rust protection and boosts the steel’s durability. It’s a favorite for many uses.

Overview of the Galvanizing Process

The hot-dip galvanizing method dips the steel in a zinc bath. This creates a strong, even zinc coating. It shields the steel from corrosion and gives a lasting, durable finish.

Benefits of Galvanized Steel: Corrosion Resistance and Cost-Effectiveness

Galvanized steel stands out for its corrosion resistance. The zinc layer protects the steel from rust and damage. It’s perfect for outdoor jobs like fencing, roofing, and sheet metal fabrication.

Also, galvanized steel is cost-effective. The zinc coating lasts long, cutting down on upkeep and replacement costs. This makes it a top pick for many industrial and commercial projects.

| Feature | Benefit |

|---|---|

| Corrosion Resistance | Protects against rust and deterioration, making it suitable for outdoor and harsh environments |

| Cost-Effectiveness | Provides long-lasting protection, reducing the need for frequent maintenance or replacement |

What is Galvannealed Steel?

Galvannealed steel is a special type of galvanized steel. It gets a unique heat treatment that makes it different. This treatment creates a zinc-iron alloy coating. This alloy improves the steel’s weldability and paintability. It’s great for use in the automotive industry and more.

The Galvannealing Process: Zinc-Iron Alloy Formation

The galvannealing process heats the steel to 800°F to 1,200°F. This heat makes the zinc coating mix with the steel. It forms a strong zinc-iron alloy layer. This layer is less shiny but sticks better, which is good for many industries.

Advantages of Galvannealed Steel: Weldability and Paintability

- Improved weldability: The zinc-iron alloy coating works better with welding. This makes welds stronger and more reliable than with standard galvanized steel.

- Enhanced paintability: The matte finish of galvannealed steel is better for paint. It helps paint stick better, reducing chipping and peeling.

Galvannealed steel is a top choice for the automotive industry. It’s great because it welds and paints well. Its versatility and performance make it valuable in many industries.

| Property | Galvanized Steel | Galvannealed Steel |

|---|---|---|

| Coating Composition | Pure Zinc | Zinc-Iron Alloy |

| Surface Appearance | Shiny | Matte |

| Weldability | Average | Excellent |

| Paintability | Good | Improved |

“The zinc-iron alloy coating on galvannealed steel provides enhanced adhesion properties, making it an ideal choice for applications where weldability and paintability are crucial factors.”

Comparing Galvanized and Galvannealed Steel

Galvanized and galvannealed steel have their own strengths and uses. Knowing the differences between them helps you choose the right steel for your project.

Strength and Durability

Galvanized steel is great for fighting off corrosion. It’s perfect for outdoor use and places where weather can be harsh. Galvannealed steel, while not as resistant to corrosion, is easier to weld and paint. This makes it ideal for certain industrial tasks.

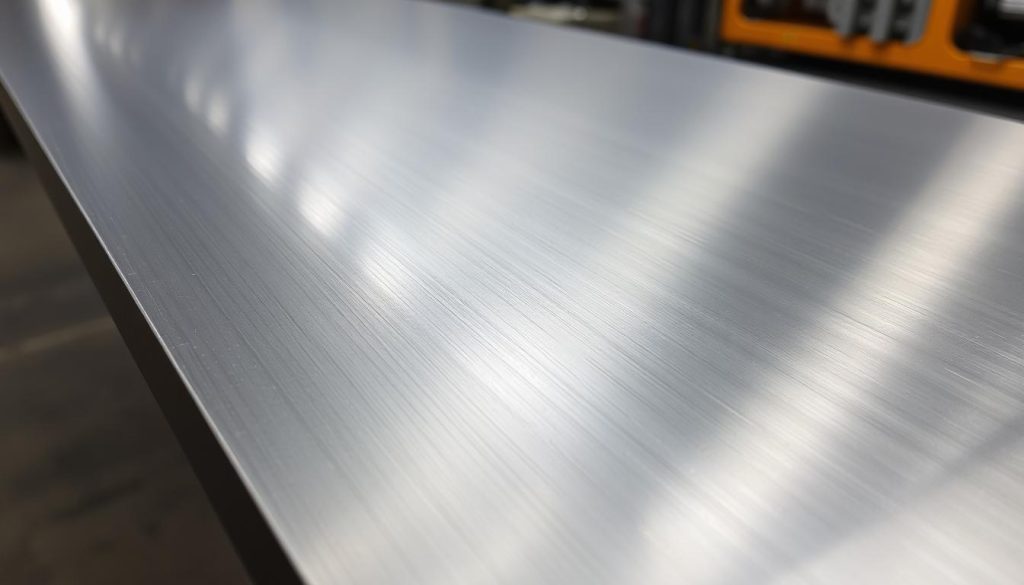

Surface Finish: Shiny vs. Matte Appearance

The look of galvanized and galvannealed steel is quite different. Galvanized steel shines with a silver look, while galvannealed steel has a dull, grayish-white finish. This look matters a lot in choosing the right steel for your project.

Best Applications for Each Type

Galvanized steel is best for outdoor projects and farm equipment. It’s great for places where rust is a big problem. Galvannealed steel, with its smooth surface, is perfect for car parts, appliances, and other items that need to be painted.

| Galvanized Steel | Galvannealed Steel |

|---|---|

| Outdoor structures | Automotive parts |

| Agricultural equipment | Appliances |

| Corrosion-prone environments | Paintable surfaces |

Understanding the differences in corrosion protection, looks, and uses of galvanized and galvannealed steel helps you pick the best for your project.

Choosing the Right Steel for Your Project

Choosing the right steel is key for success in fabrication and construction. Both galvanized and galvannealed steel have their own benefits. The choice depends on cost, strength needs, and where the steel will be used.

Factors to Consider

It’s important to think about steel selection, project requirements, and environmental factors for cost-effectiveness and performance. Here are key points to consider when choosing between galvanized and galvannealed steel:

- Cost: Galvanized steel is cheaper because it’s easier to make. But, consider if it fits your project’s needs.

- Strength and Durability: The project’s strength and durability needs will guide your choice. Galvannealed steel is stronger, while galvanized is better at resisting corrosion.

- Usage Environment: The project’s location, indoors or outdoors, affects corrosion resistance and finish needs. Galvanized is better for outdoors, and galvannealed for indoors where a smooth look is important.

By carefully looking at these factors, you can make the best choice for your project. This ensures cost-effectiveness and success, whether you need galvannealed’s strength or galvanized’s corrosion resistance.

“Selecting the right steel type is crucial for the success of any fabrication or construction project. By considering the cost, strength, and usage environment, you can ensure your project meets the desired performance and budget requirements.”

Tailored Solutions with Galvanized and Galvannealed Steel

In today’s fast-paced world, making steel solutions fit exactly what’s needed is key. Galvanized and galvannealed steel are great for many industries. They meet the exact needs of construction and metal work.

Galvanized steel is loved for its strong fight against corrosion and its affordable price. It’s perfect for places outside where things get rough. On the other hand, galvannealed steel is better for welding and painting. It’s great for projects that need to look good and work well together.

Using these steels, makers and builders can create custom solutions just right for their projects. Whether it’s for strong building materials or flexible parts, galvanized and galvannealed steel are up to the task. They help meet the changing needs of today’s industries.