In the world of manufacturing and quality control, a new technology has changed the game: the Coordinate Measuring Machine (CMM). But what is CMM inspection, and why is it so important for precision and excellence? Let’s explore this technology and its secrets.

Ever wondered how your favorite products’ parts fit together perfectly? The answer is CMM inspection’s precision. But how does it work, and why is it key for modern manufacturing? Get ready for a journey that will change how you see quality control.

What is CMM Inspection?

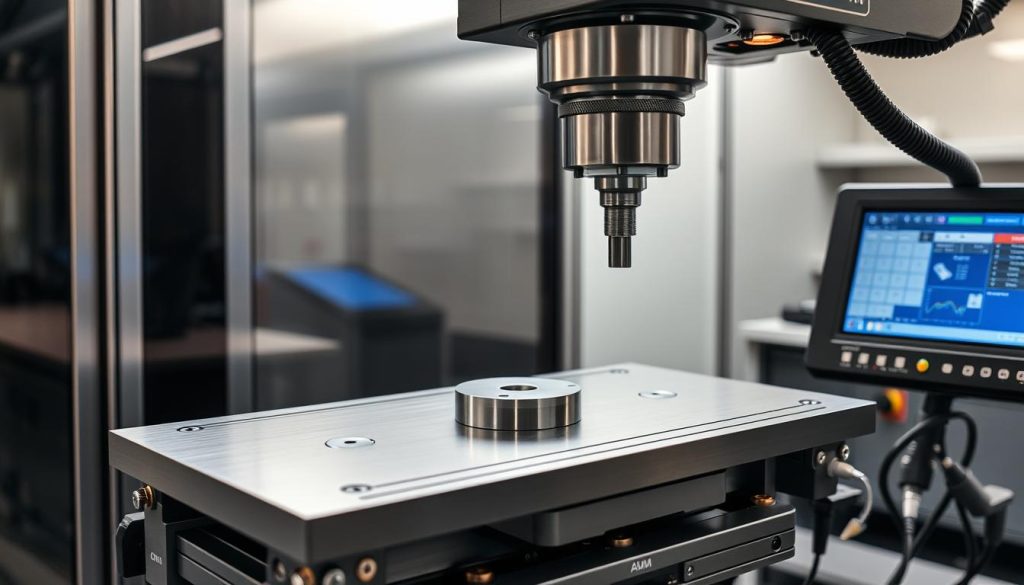

Coordinate Measuring Machine (CMM) inspection is a precise way to measure things in manufacturing and quality control. It uses advanced 3D tools and software to check if products, parts, and prototypes are accurate and consistent.

Definition and Overview

CMM inspection uses a Coordinate Measuring Machine to measure an object’s size, shape, and other details. The machine has a probe system that moves in different directions. This lets CMMs take detailed 3D measurements, helping manufacturers understand their products well.

Key Components of a Coordinate Measuring Machine (CMM)

A CMM system has key parts, including:

- Probe System: The probe is the main tool for measuring, tracking the object’s surface.

- Measurement Bed: This is where the object sits, letting the probe reach all needed areas.

- Software Analysis: Special software handles the 3D data from the CMM. It helps with quality checks and making new designs.

| Component | Description |

|---|---|

| Probe System | The probe is the main tool for measuring, tracking the object’s surface. |

| Measurement Bed | This is where the object sits, letting the probe reach all needed areas. |

| Software Analysis | Special software handles the 3D data from the CMM. It helps with quality checks and making new designs. |

“CMM inspection is a critical tool for ensuring the accuracy and precision of manufactured products, allowing companies to maintain high quality standards and remain competitive in their industries.”

Types of CMMs

There are many types of coordinate measuring machines (CMMs), each with special features. They include bridge CMMs, gantry CMMs, and portable CMMs. These options help meet different measurement needs.

Bridge CMMs

Bridge CMMs are the most common. They have a fixed bridge that holds the measurement probe. This setup allows for precise measurements within a certain area. Fixed CMMs are very accurate and reliable. They are great for checking the quality of parts in industries like aerospace and automotive.

Gantry CMMs

Gantry CMMs have a moving bridge that goes over a fixed base. This design lets them measure bigger parts and move around more. Gantry CMMs are perfect for large items in construction, shipbuilding, and energy.

Portable CMMs

Portable CMMs, like articulated arm and optical CMM systems, are great for moving around. They’re useful for checking parts on-site. Laser tracker technology is also portable and precise for big measurements.

Knowing the differences between CMM types helps choose the right one. This ensures precision and accuracy in various processes.

Benefits of CMM Inspection

CMM (Coordinate Measuring Machine) inspection is a game-changer in precision manufacturing. It offers dimensional accuracy that is unmatched. Every custom part meets the highest quality standards thanks to this advanced technology.

High Precision and Accuracy in Measurements

The non-contact measurement of CMMs is incredibly precise. It can collect data with uncertainties less than a micron. This precision is vital in industries like aerospace, automotive, and medical devices. Even small errors can have big consequences.

Applications in Quality Assurance and Reverse Engineering

CMM inspection is key in quality assurance. It helps manufacturers check if their products meet standards quickly and efficiently. The data from automated inspection also aids in reverse engineering. This lets companies improve and replicate designs with precision.

“The unparalleled precision of CMM inspection is a game-changer in the world of custom parts manufacturing. It’s not just about meeting specifications – it’s about exceeding them and delivering the highest quality products possible.”

Using CMM inspection opens up new possibilities for manufacturers. It leads to better product quality, lower costs, and faster production. This technology is revolutionizing precision manufacturing.

Industries That Rely on CMM Inspection

In the world of precision engineering, certain industries heavily use CMM inspection technology. The aerospace, automotive, medical devices, and consumer electronics markets rely on CMM’s accuracy and reliability. These fields need CMM to ensure their products meet high standards.

Aerospace and Automotive Manufacturing

The aerospace and automotive sectors are all about precision. Even small errors can be disastrous. They use CMM to check their products’ dimensions, from engine parts to car panels. This ensures their products are safe and meet strict standards.

Medical Devices and Consumer Electronics

In the fast-paced world of medical devices and consumer electronics, CMM is key. It helps validate the complex designs of these products, from implants to smartphones. CMM ensures these products are safe and perform well, meeting customer expectations.

| Industry | Reliance on CMM Inspection | Key Factors |

|---|---|---|

| Aerospace | High | Precision engineering, complex geometries, regulatory compliance |

| Automotive | High | Precision engineering, complex geometries, product validation |

| Medical Devices | High | Precision engineering, complex geometries, regulatory compliance |

| Consumer Electronics | High | Precision engineering, complex geometries, product validation |

The need for precision and quality is growing in these industries. CMM inspection will become even more important for staying competitive. By using CMM, manufacturers can ensure their products succeed globally.

Shixinproto’s CMM Inspection Services

At Shixinproto, we provide top-notch CMM inspection services for many industries. Our team uses advanced equipment to ensure your products meet the highest standards. We focus on precision and accuracy in every inspection.

Our services are perfect for aerospace, automotive, medical devices, and consumer electronics. We use the latest technology to help with quality control and rapid prototyping. Our goal is to exceed your expectations with our solutions.

We’re committed to excellence and meeting each project’s unique needs. Our clients rely on us to ensure their products’ quality and performance. We aim to deliver results that help our clients succeed.