In today’s world, the electroplating process is key in making metal products last longer and look better. It’s used in many places, from factories to homes. But, what makes this technology so special?

Electroplating is a detailed method that adds a thin layer of metal to a conductive surface using electricity. It makes the surface look great and also protects it from damage. This is because it fights off corrosion, wear, and other harmful effects.

What is Electroplating?

Electroplating is a method to add a thin metal layer to a surface using electrolysis. It’s a key technique in many industries. It makes surfaces better by adding a protective layer. This process is known for its electroplating process functionality.

Definition and Overview

Electroplating uses an electric current to deposit metal on a conductive surface. The surface, called the cathode, is dipped in a solution of metal ions. When electricity is applied, the metal ions are reduced and stick to the surface, creating a uniform layer.

The Role of Electrolytic Cells in Electroplating

Electrolytic cells are vital in electroplating. They hold the electrolyte solution, which carries the electric current. The substrate is connected to the negative terminal, and the positive terminal is linked to a metal anode. This setup allows metal ions to move to the substrate, forming a thin, even layer.

“Electroplating is a versatile and widely-used surface finishing technique that can enhance the functionality, durability, and aesthetic appeal of a wide range of materials and products.”

Key Steps in the Electroplating Process

The electroplating process is complex and fascinating. It changes the surface of different materials. Let’s explore the main steps of this amazing process.

Surface Preparation and Cleaning

Getting the surface ready is key for electroplating success. It must be cleaned and degreased to remove dirt or impurities. This might involve chemical etching, mechanical polishing, or sandblasting, depending on the material and finish needed.

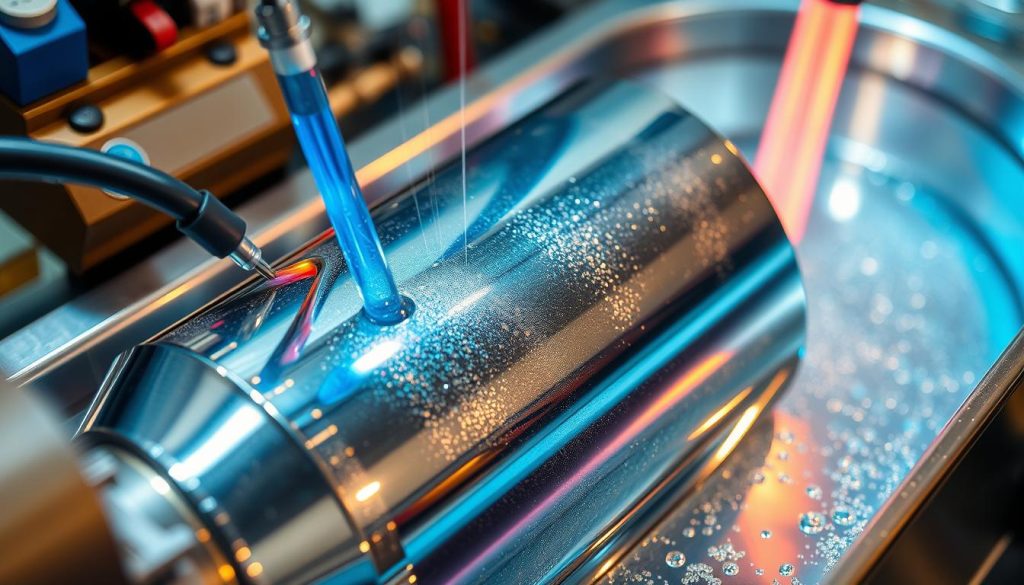

Electrolyte Bath and Metal Deposition

The electrolyte bath is at the heart of electroplating. It has metal ions that coat the surface. An electric current draws these ions to the surface, creating a uniform layer. The bath’s composition and temperature are carefully managed for the best coating.

Post-Treatment and Finishing

After the metal is deposited, the surface may get extra treatments. This includes rinsing, drying, or polishing. These steps enhance the surface’s look, protection, or function.

By understanding these steps, the electroplating process can be customized. It can improve surface preparation and create the right electrolyte bath for various needs.

Benefits of Electroplating

Electroplating is a versatile metal finishing technique that offers many benefits. It enhances corrosion resistance and improves aesthetics and conductivity. Shixinproto is a leader in this field, understanding the advantages of electroplating for various industries.

Enhanced Corrosion Resistance

Electroplating protects metal surfaces from corrosion. It deposits a thin layer of a more resistant metal, like chrome or nickel. This barrier shields the metal from moisture, chemicals, and UV exposure.

This protection can greatly extend the life of components. It makes products more reliable, especially in harsh environments. So, electroplating is a valuable solution for many applications.

Improved Aesthetics and Conductivity

Electroplating also enhances aesthetics and functionality. It creates a smooth, uniform, and glossy finish. This improves the look of products, from car accessories to jewelry and decorations.

Moreover, it can boost the conductivity of metal surfaces. This makes it ideal for the electronics and medical device industries. Here, improved conductivity is key for product performance.

| Benefit | Description |

|---|---|

| Corrosion Resistance | Electroplating creates a protective barrier that shields metal surfaces from the damaging effects of environmental factors, such as moisture, chemicals, and UV exposure. |

| Improved Aesthetics | The electroplating process can create a smooth, uniform, and glossy finish, enhancing the visual appeal of a wide range of products. |

| Improved Conductivity | Electroplating can improve the conductivity of metal surfaces, making it a popular choice for applications in the electronics and medical device industries. |

“Electroplating is a game-changer for industries seeking to enhance the corrosion resistance, aesthetics, and conductivity of their products. The versatility and precision of this process make it an invaluable tool for modern manufacturing.”

Shixinproto is a leading provider of electroplating solutions. They help clients maximize the benefits of this technology. With a focus on quality, innovation, and customer satisfaction, Shixinproto continues to push the boundaries of what’s possible with electroplating functionality.

Common Applications of Electroplating

Electroplating is very useful in many fields. It makes car parts better and helps create advanced medical tools. This method is used in many ways.

Automotive Components and Accessories

In the car world, electroplating is key. It makes parts last longer, look better, and resist rust. It’s used for shiny trim and for parts that need to carry electricity.

Electronics and Medical Devices

Electroplating is also big in electronics and medicine. It makes sure electronics work well by adding special coatings. In medicine, it helps make implants and tools safe and strong.

Jewelry and Decorative Items

Electroplating is also great for making jewelry and decorations. It creates beautiful, lasting finishes. This makes jewelry and decorations stand out.

| Application | Benefits of Electroplating |

|---|---|

| Automotive Components | Improved corrosion resistance, durability, and aesthetic appeal |

| Electronics and Medical Devices | Precise conductive coatings, durable and biocompatible surfaces |

| Jewelry and Decorative Items | Stunning, long-lasting finishes and intricate designs |

Electroplating is a must-have in many industries. It will keep growing as technology gets better. This makes it a key part of making things.

Shixinproto’s Electroplating Solutions

At Shixinproto, we’re proud of our electroplating skills. We use our knowledge to create precise surface coatings for many industries. Our team is committed to offering custom electroplating services that meet our clients’ needs, ensuring top-notch results.

High-Precision Surface Coatings for Diverse Industries

Our electroplating solutions are known for their high quality and versatility. With advanced facilities and technology, we make coatings that improve product functionality, durability, and look. This includes everything from car parts and accessories to electronics and medical gear. We’re always innovating to set new standards in surface finishing.

Tailored Electroplating Services to Meet Your Needs

We know every client is different at Shixinproto. That’s why we have a wide range of electroplating services. Whether you need to protect your car parts, boost your electronics, or add style to your jewelry, we’ve got you covered. Our team will work with you to create a custom solution that goes beyond your expectations. You can count on Shixinproto for quality and satisfaction in electroplating.