Laser technology has changed the game in modern manufacturing. It’s now key for making many products, from cutting and welding to engraving and drilling. But what are these methods, and how do they help different industries? Let’s explore the amazing uses of this advanced tech.

Laser processing, a Cutting-Edge Technology Revolutionizing Manufacturing

Key Takeaways

- Explore the diverse range of laser processing techniques and their applications across industries

- Understand how lasers work in modern manufacturing, from precision cutting to high-strength welding

- Discover the benefits of laser processing, including improved precision, reduced material waste, and enhanced flexibility

- Dive into the real-world applications of laser technology, from automotive and aerospace components to medical devices and consumer goods

- Gain insights into the future of laser processing and its role in shaping the next generation of manufacturing

Overview of Laser Processing

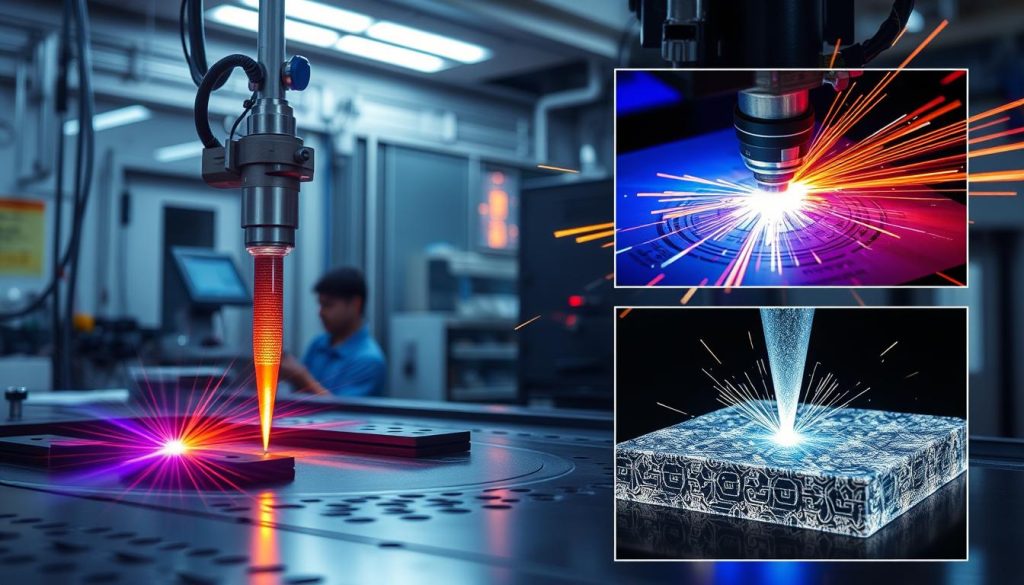

Laser beam processing is key in today’s industrial world. It changes how we cut, weld, engrave, and drill materials. This tech uses laser beams to work on many materials with great speed and accuracy.

How Lasers Work in Manufacturing

Lasers create focused, single-color light beams. By adjusting the beam’s power and focus, makers get precise results. This makes manufacturing more versatile and accurate.

Types of Lasers Used in Processing

There are many laser types for industrial use. CO2 lasers and fiber lasers are popular. Each has its own strengths for different tasks.

| Laser Type | Advantages | Typical Applications |

|---|---|---|

| CO2 Lasers | High power output, good beam quality, and cost-effective | Cutting and welding of metal sheets, plastics, and fabrics |

| Fiber Lasers | Compact size, high energy efficiency, and excellent beam quality | Precision cutting and welding of thin metal parts, as well as laser marking and engraving |

Knowing what each laser can do helps makers pick the right one. This ensures their work is efficient and of high quality.

“The versatility of laser processing has revolutionized modern manufacturing, allowing us to achieve unprecedented levels of precision, speed, and material flexibility.”

Key Laser Processing Methods

Laser technology has changed many manufacturing processes. It offers a precise and versatile solution for many applications. We will look at the main laser processing methods used today.

Laser Cutting: Precision and Versatility

Laser cutting is very accurate and efficient. It uses a focused laser beam to cut through materials, from thin sheets to thick plates. This method is great for making intricate shapes, which is why it’s popular in industries like automotive and aerospace.

Laser cutting is precise, reduces waste, and is cost-effective. It’s a sustainable solution for many needs.

Laser Welding: High-Strength Bonds

Laser welding uses a concentrated laser beam to fuse materials, creating strong bonds. It’s useful when traditional welding is hard or impractical, like with small parts or different materials. This method offers precise control, resulting in strong bonds with minimal distortion.

It’s a good choice for industries like automotive, aerospace, and electronics.

Laser Engraving and Marking: Aesthetic and Functional

Laser engraving and marking use a laser beam to etch or mark surfaces. This includes metals, plastics, and ceramics. It’s precise and can make detailed designs, logos, or serial numbers.

This method is popular for product identification, branding, and decoration. It’s used in industries like electronics, medical devices, and luxury goods.

Laser Drilling: Microscopic Precision

Laser drilling creates precise, microscopic holes in various materials. It’s great for making small, accurate holes in components like fuel injectors and electronic circuits. This method offers high precision and can create complex hole shapes.

It’s a valuable tool for industries needing advanced manufacturing capabilities.

“Laser processing methods have revolutionized the way we manufacture products, offering unparalleled precision, speed, and efficiency across a wide range of industries.”

Benefits of Laser Processing

Laser processing brings many advantages to modern manufacturing. It’s known for its precision, speed, and ability to cut down on waste. These benefits are changing the game in how we make things.

High Precision and Speed

Laser processing is incredibly precise. It can make cuts, welds, and engravings with amazing accuracy. This precision means fewer mistakes and better products, making manufacturing more efficient.

It’s also very fast. Laser methods can do tasks much quicker than old ways. This makes production faster and helps meet high demand.

Reduced Material Waste

Laser processing is better at using materials than old methods. It needs less material for the same job, cutting down on waste. This is good for the planet and saves money, making manufacturing more sustainable.

Flexibility Across Multiple Industries

Laser processing works well in many fields, like cars, planes, medical tools, and more. Its flexibility helps solve different problems in various industries. This drives innovation and makes things more efficient everywhere.

| Benefit | Description |

|---|---|

| High Precision and Speed | Laser beams can be precisely focused, enabling intricate cuts, welds, and engraving with exceptional accuracy. Laser-based techniques also offer remarkable speed, streamlining production and improving throughput. |

| Reduced Material Waste | Laser processing techniques are more material-efficient, minimizing the amount of material required and reducing waste, contributing to cost savings and sustainable manufacturing. |

| Flexibility Across Multiple Industries | The versatility of laser processing allows it to be applied across a wide range of industries, from automotive and aerospace to medical devices and consumer goods, driving innovation and efficiency. |

“Laser processing has revolutionized modern manufacturing, offering unparalleled precision, speed, and material efficiency. Its versatility across industries makes it a game-changer in the pursuit of efficient and sustainable production.”

Applications of Laser Processing

Laser processing is key in many industries today. It’s used in making car parts, aircraft components, medical devices, and more. This technology has changed how we design and make these products.

Automotive and Aerospace Components

Laser processing is a big deal in cars and planes. It makes parts like fuel injectors and engine parts more precise and light. In planes, it helps make parts that are both strong and light.

These industries need laser processing for its accuracy and speed. It helps them stay at the forefront of innovation.

Medical Devices and Consumer Goods

Laser processing is also vital in healthcare. It’s used to make tiny parts for medical tools and implants. This ensures they are precise and safe for patients.

It’s not just for medical use. Laser processing also makes consumer goods better. This includes custom electronics and top-notch home appliances, focusing on looks and function.