In today’s fast-paced manufacturing world, precision and efficiency are key. CNC turning has changed the game in metal fabrication. But what’s so special about it, and how can it help your business?

Did you know CNC turning can bring accuracy, consistency, and cost savings to your production? Get ready to learn about this amazing machining method. See how it can take your manufacturing to the next level.

What is CNC Turning?

CNC turning is a precise way to make cylindrical parts. It uses computer-controlled lathes to shape, drill, and cut workpieces. This method has changed the manufacturing world, making it possible to create detailed cylindrical parts with great precision.

Definition and Core Principles

CNC turning is a subtractive process that uses a computer-controlled lathe. It removes material from a spinning workpiece, usually a cylindrical part. The computer program, called G-code, controls the lathe’s tools, making complex shapes with high accuracy.

How CNC Turning Differs from Other Machining Methods

CNC turning is different from manual lathe operations because it doesn’t need human help. This reduces errors and boosts efficiency. It’s better than milling or grinding for making cylindrical parts because it can create detailed features with great lathe operation precision.

This method also works well for making small or large batches. It’s great for computer numerical control prototyping and big production runs.

“CNC turning is the backbone of modern precision manufacturing, enabling the creation of complex cylindrical parts with unparalleled accuracy and efficiency.”

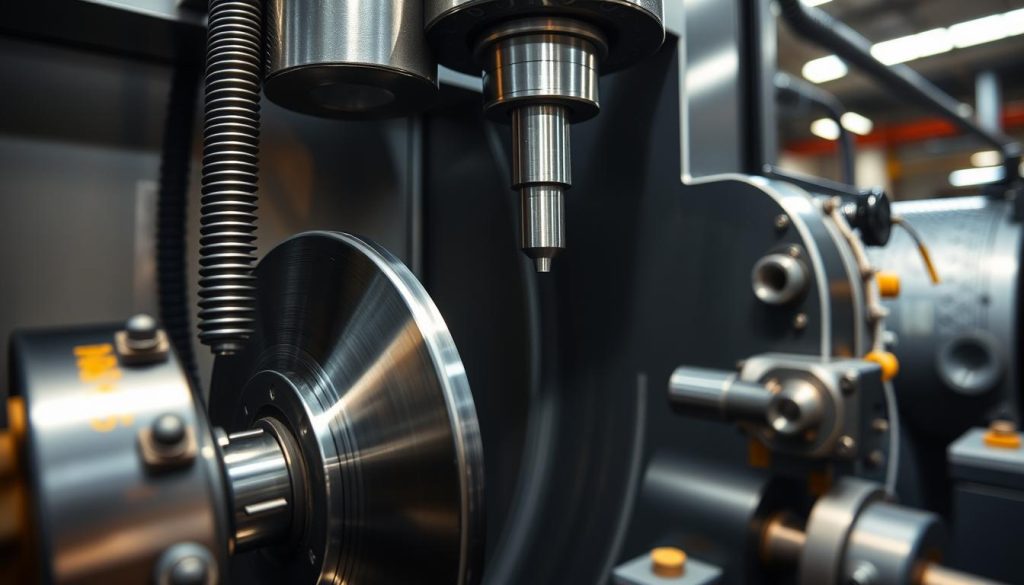

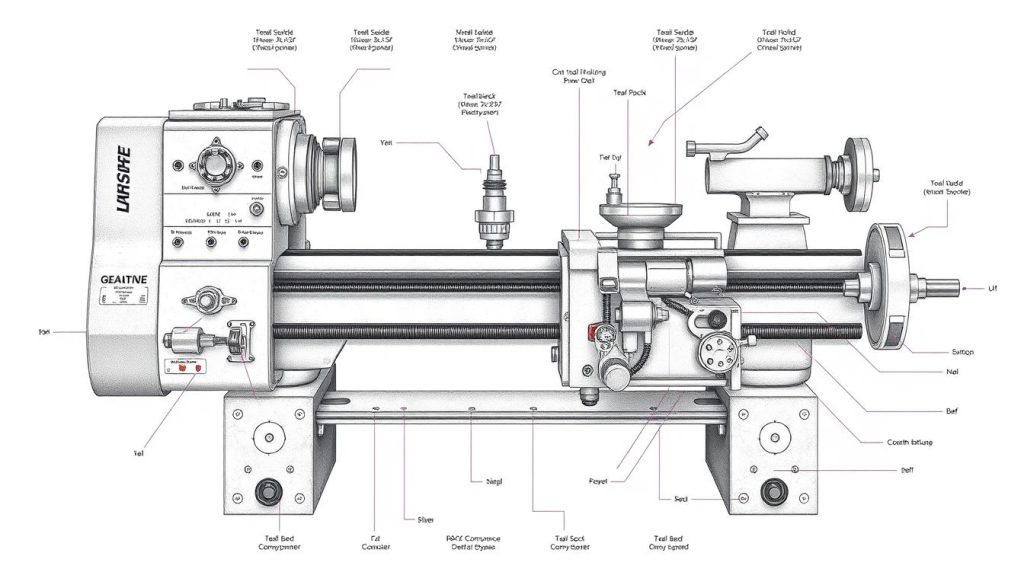

Key Components of CNC Turning Machines

The precision and performance of CNC turning depend on many important parts working together. From the strong CNC lathe components to the advanced control systems, each part is crucial for making high-quality parts and components.

The Role of Chucks, Spindles, and Tool Turrets

The chuck holds the workpiece firmly in place at the center of a CNC turning machine. The spindle then rotates it at exact speeds. The tool holders and cutting tools are on a tool turret that can change tools automatically. This allows for complex machining tasks.

| Component | Function |

|---|---|

| Chuck | Holds the workpiece securely during the turning process |

| Spindle | Rotates the workpiece at the desired speed for material removal |

| Tool Turret | Holds multiple cutting tools and enables automated tool changes |

Control Systems for Precision Operation

Advanced control systems are the core of CNC turning. They allow for precise programming and control of the machine’s actions. These systems use computer-aided software to manage the machine’s operations. This ensures consistent, high-quality results with little need for human intervention.

“The key to successful CNC turning lies in the seamless integration of these essential components, each playing a critical role in delivering the precision and efficiency that modern manufacturing demands.”

Benefits of CNC Turning

CNC (Computer Numerical Control) turning has changed the game in modern manufacturing. It brings many benefits like manufacturing efficiency, quality control, and production scalability. This advanced method is now the top choice for businesses looking to lead the way.

High Precision and Consistency

CNC turning stands out for its high precision and consistency. The computer controls the process, making each part accurate to just a few microns. This means the finished products are of top quality, needing less post-processing and fewer defects.

Cost Efficiency for Small and Large Batches

CNC turning is great for both small and big production runs. Its automated nature means quick changes, making it efficient for custom or low-volume parts. This flexibility appeals to many industries, from cars and planes to medical devices.

| Benefit | Description |

|---|---|

| High Precision | CNC turning can achieve tolerances of just a few microns, ensuring superior quality control and minimizing the need for post-processing. |

| Consistent Quality | The computer-controlled nature of CNC turning ensures that each component is manufactured with exceptional consistency, reducing the risk of defects. |

| Cost-Effective for Small and Large Batches | CNC turning is highly adaptable, allowing for rapid changeovers and making it a viable option for both small and large-scale production scalability. |

Using CNC turning, manufacturers can achieve better manufacturing efficiency, quality control, and production scalability. This leads to delivering top-notch products to customers.

Applications of CNC Turning

CNC (Computer Numerical Control) turning is key in many industries. It helps make precise parts quickly and accurately. This technology is used in car, plane, and medical device making, showing its wide range of uses.

Automotive, Aerospace, and Medical Device Manufacturing

In the car world, CNC turning makes important parts like engine bits and gears. It creates parts with exact shapes and sizes, making cars run better.

The plane and space world also uses CNC turning. It makes parts like turbine blades and landing gear. This is crucial for safety in these fields.

Medical devices also benefit from CNC turning. It makes parts for implants and tools, needing high precision and consistency.

Prototyping and Custom Component Production

CNC turning is great for making prototypes and custom parts. It helps designers and engineers make quick, affordable custom parts. This speeds up the process of bringing new products to market.

It’s also good for making special parts or unique items. CNC turning’s flexibility and precision are valuable in many fields.

| Industry | CNC Turning Applications |

|---|---|

| Automotive | Engine parts, transmission gears, suspension systems |

| Aerospace | Turbine blades, landing gear components |

| Medical Devices | Orthopedic implants, surgical instruments |

| Prototyping and Custom Components | Specialized industrial parts, unique one-off pieces |

“CNC turning has revolutionized the way we approach industrial manufacturing, enabling us to push the boundaries of precision and efficiency across a wide range of sectors.”

Shixinproto’s CNC Turning Services

At Shixinproto, we’re proud of our CNC turning services. They offer precision and scalability for many industries. Our skilled engineers and top-notch equipment help us create custom solutions for our clients.

Custom Solutions for Precision and Scalability

Need intricate parts for cars or precise medical devices? Shixinproto’s CNC turning is up to the task. Our advanced machines and strict quality checks mean we can handle small or big orders with ease.

Why Shixinproto is Your Trusted CNC Partner

Shixinproto is all about top-notch CNC machining, custom manufacturing, and quality. Our history of great results and focus on customer happiness makes us a reliable choice. We work hand-in-hand with our clients to meet their project needs with precision and speed.