In the world of precision manufacturing, choosing between a CNC Swiss lathe and a traditional CNC lathe is crucial. Both have unique strengths and uses. This article will help you understand the differences, so you can make the best choice for your business.

Are you looking for a CNC machining solution or just curious about the latest advancements? Knowing the differences between CNC Swiss lathes and CNC lathes is key. By exploring their design, functionality, and applications, you can find the perfect fit for your needs. This ensures your products are of high quality and tailored to your specifications.

What is a CNC Lathe?

In today’s manufacturing world, the CNC lathe is a key player. It’s a machine that combines computer control with traditional turning. This makes it a must-have in many fields, from cars to planes.

Overview of CNC Lathe

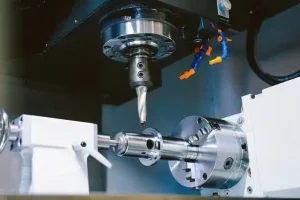

A CNC lathe is a machine that cuts and shapes metal automatically. It’s different from manual lathes, where you control the tools by hand. Instead, a CNC lathe follows a set of instructions to make parts with great accuracy and consistency.

CNC Lathe Components and Working Principles

The CNC lathe has important parts that work together. These include:

- The spindle, which spins the workpiece fast

- The cutting tools, which shape and remove material

- The servo motors, which move the tools and workpiece precisely

- The computer numerical control (CNC) system, which runs the whole show

The CNC lathe works by controlling these parts together. This lets it do complex tasks with great precision.

Benefits of Using CNC Lathe

CNC lathes have many benefits in modern manufacturing. They are a top choice for many reasons. Some of these include:

- Improved Precision and Consistency: CNC lathes make parts with unmatched accuracy, ensuring tight tolerances and fewer defects.

- Enhanced Efficiency: Automated processes and less setup time mean more work done faster, helping meet tight deadlines.

- Versatility in Machining: CNC lathes can work with many materials, from metals to plastics, and make complex shapes easily.

- Reduced Labor Costs: CNC lathes need fewer people to run, as they do most of the work on their own.

These advantages, along with advances in computer control, make CNC lathes essential for metal cutting and precision manufacturing.

What is a CNC Swiss Lathe?

A CNC Swiss lathe, also known as a Swiss-type lathe, is a special machine for making small, detailed parts with great precision. It’s different from regular CNC lathes because of its unique setup. This includes a sliding headstock and guide bushing.

Definition of CNC Swiss Lathe

The CNC Swiss lathe is a CNC machine with a sliding headstock and guide bushing. It’s designed to handle long, thin workpieces. This makes it great for making complex, small parts for industries like medical, electronics, and aerospace.

CNC Swiss Lathe Components and Operations

The main parts of a CNC Swiss lathe are the sliding headstock, guide bushing, and tool turret. The sliding headstock holds the workpiece, and the guide bushing supports it. This setup allows for making long, thin parts with high accuracy. The tool turret moves to perform various machining tasks.

Advantages of CNC Swiss Lathes

CNC Swiss lathes have many benefits over traditional CNC lathes. They include:

- Enhanced precision and accuracy in producing small, complex parts

- Increased efficiency and productivity due to the ability to perform multiple operations simultaneously

- Reduced material waste and improved material utilization thanks to the guide bushing support

- Suitability for manufacturing a wide range of parts, from medical devices to electronic components

The Swiss lathe’s design, with its sliding headstock, guide bushing, and CNC technology, makes it a versatile and valuable tool. It’s perfect for businesses looking to make high-quality, intricate parts efficiently and cost-effectively.

Key Differences Between CNC Swiss Lathe and CNC Lathe

Choosing between a CNC Swiss lathe and a traditional CNC lathe can greatly affect your product’s quality. These lathes differ in design, function, and what they’re best for.

Design and Functionality

CNC Swiss lathes have a unique, compact design. They have a guide bushing that holds the workpiece close to the tool. This setup allows for very precise work on complex parts. On the other hand, standard CNC lathes have an open design. They rely on the workpiece’s strength and the machine’s stability for accuracy.

Precision and Speed

CNC Swiss lathes are top-notch in machining capabilities and part complexity. Their design lets them achieve tight tolerances and smooth finishes. They can also do many operations on one part without needing to re-chuck it. This means they work faster and more efficiently. Traditional CNC lathes, however, can go faster and handle bigger parts.

Applications and Use Cases

CNC Swiss lathes are great for making small, detailed parts like medical devices and electronics. They’re perfect for complex shapes and can do many steps in one go. Standard CNC lathes, though, are better for bigger, simpler parts. They’re often used in the automotive and aerospace industries.

| Factors | CNC Swiss Lathe | CNC Lathe |

|---|---|---|

| Design | Compact, chucker-style with guide bushing | Open-frame design |

| Precision | Exceptional, tighter tolerances, better surface finishes | Good, but not as precise as CNC Swiss lathes |

| Part Complexity | Highly capable of handling intricate, complex parts | Better suited for larger, less complex parts |

| Production Efficiency | Improved efficiency and reduced lead times | Slightly less efficient for complex parts |

| Typical Applications | Medical devices, electronics, micromachining | Automotive, aerospace, general manufacturing |

Choosing Between CNC Swiss Lathe and CNC Lathe

Choosing between a CNC Swiss lathe and a traditional CNC lathe is key to improving your manufacturing. It affects your efficiency, part quality, and costs. Knowing the strengths of each machine helps pick the best for your needs.

When to Use a CNC Swiss Lathe

The CNC Swiss lathe is great for making small, detailed parts quickly and accurately. It’s perfect for complex items like medical tools, electronics, and car parts. It works well with many materials, like stainless steel and titanium, for small to medium batches.

When to Use a CNC Lathe

For bigger parts and lots of them, a traditional CNC lathe is the better choice. It’s good for making simple shapes like shafts and bushings. While not as precise as the Swiss lathe, CNC lathes save money for making lots of parts. They’re great for car, plane, and general manufacturing industries.

| Feature | CNC Swiss Lathe | CNC Lathe |

|---|---|---|

| Part Complexity | Highly complex, intricate parts | Simpler, cylindrical parts |

| Precision | Exceptional, tight tolerances | Good, but not as precise as CNC Swiss |

| Production Volume | Low to medium | Medium to high |

| Cost-Effectiveness | Higher investment, but suitable for low-volume, high-precision parts | Lower investment, better for high-volume production |

Think about what you need in terms of part details, how many you’ll make, and the cost. This helps decide between a CNC Swiss lathe and a traditional CNC lathe. The right choice can make your manufacturing better and save you money.

Shixinproto’s Lathe Services: High-Precision and Custom Manufacturing

At Shixinproto, we’re proud of our skills in CNC Swiss lathe and CNC lathe machining. Our top-notch facilities and talented team are ready to provide precise and custom-made solutions. We aim to meet the varied needs of our clients.

Looking for custom machining, prototyping, or production machining? Shixinproto can meet your high standards. Our advanced CNC technology and dedication to quality ensure every project is done with care and precision.

Our team can handle complex parts and specialized components. We know each client is different, so we tailor our services for the best results. We’re here to help you achieve your goals.