In modern manufacturing, CNC milling and CNC turning stand out. These precision methods are key for making complex parts in many fields. But, which one is best for your project? What are the main differences between CNC milling and CNC turning, and how do you pick the right one?

This guide will explore CNC milling and CNC turning in detail. We’ll look at their unique strengths, benefits, and uses. Knowing these differences will help you make smart choices for your next project.

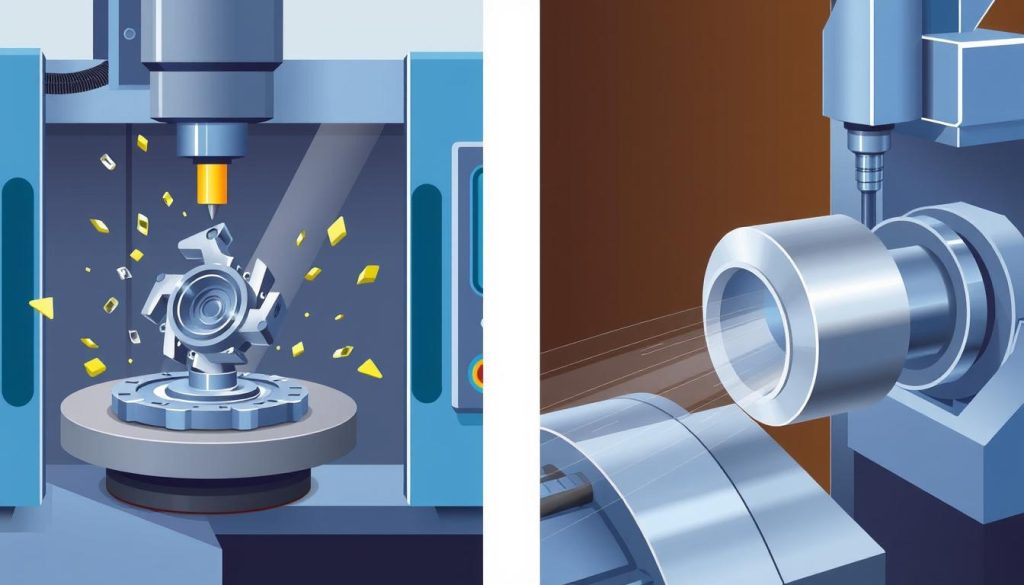

What is CNC Milling?

CNC milling is a computer-controlled process that uses end mills to shape workpieces. It’s different from manual milling because it automates the process. This makes it possible to create precise and complex parts easily.

How CNC Milling Works

In a CNC milling machine, the workpiece sits on a table that moves in different directions. The cutting tool spins on a spindle. The machine’s computer controls both, making it easy to create detailed shapes.

This method is great for making flat, curved, and three-dimensional surfaces. It does so with high accuracy.

Benefits for Flat and Complex Shapes

CNC milling is excellent for making various part shapes, from simple to complex. It uses multi-axis machines and end mills to create parts with detailed features. This is especially useful in industries like aerospace and medical devices.

| CNC Milling Capabilities | Examples |

|---|---|

| Flat Surfaces | Machined Plates, Brackets, and Mounting Surfaces |

| Complex Shapes | Turbine Blades, Orthopedic Implants, and Automotive Engine Parts |

“CNC milling allows us to rapidly produce parts with intricate geometries that would be nearly impossible to create through manual machining. This has been a game-changer for our product development and manufacturing processes.”

– John Smith, Engineering Manager at XYZ Manufacturing

What is CNC Turning?

CNC turning, also known as lathe machining, is a subtractive manufacturing process. It uses a rotating workpiece and stationary cutting tools to create cylindrical parts. Unlike CNC milling, which is great for flat and complex shapes, CNC turning is perfect for parts with rotational symmetry, like shafts and bolts.

Overview of CNC Turning Operations

In CNC turning, the workpiece is clamped in a rotary chuck and spun fast. As it rotates, stationary cutting tools are moved along the surface. They remove material to shape the desired cylindrical form.

This process is efficient for creating parts with circular cross-sections. It uses the natural rotational motion to boost productivity.

Advantages for Cylindrical Parts

- High-precision manufacturing of rotationally symmetric parts

- Efficient material removal for cylindrical geometries

- Excellent surface finishes on turned components

- Ability to create complex features like threads, grooves, and tapers

- Cost-effective production of large quantities of cylindrical parts

CNC turning is a streamlined and economical solution for many industries. It’s great for making cylindrical components in automotive, aerospace, medical, and industrial machinery.

Key Differences Between Milling and Turning

CNC machining has two main processes: milling and turning. Each offers unique benefits. Knowing the differences helps improve efficiency and quality in manufacturing.

Cutting Motion and Tooling

The main difference is in how the material is cut. Milling uses a rotating cutter that moves across the workpiece. This removes material in a linear or circular pattern. Turning, on the other hand, uses a stationary cutting tool on a rotating workpiece. It’s great for making cylindrical or tapered shapes.

The tools used also vary. Milling uses end mills and face mills, while turning uses single-point tools like lathe bits and inserts.

Suitable Materials and Shapes

Milling is good for making flat surfaces and complex shapes. It works well with many materials, including metals, plastics, and composites. Turning is best for making cylindrical parts like shafts and tubes. It’s often used with metals and engineering plastics.

Efficiency and Cost Considerations

The choice between milling and turning depends on the project. Turning is faster for making lots of simple cylindrical parts. Milling is better for making complex parts in smaller quantities.

| Characteristic | CNC Milling | CNC Turning |

|---|---|---|

| Cutting Motion | Rotating cutter, linear or circular | Rotating workpiece, stationary tool |

| Tooling | End mills, face mills, multi-tooth cutters | Single-point tools (lathe bits, inserts) |

| Suitable Shapes | Flat surfaces, complex geometries | Cylindrical, rotationally symmetric parts |

| Suitable Materials | Metals, plastics, composites | Metals, engineering plastics |

| Manufacturing Efficiency | Suitable for low-to-medium volume | Efficient for high-volume production |

Understanding these differences helps manufacturers choose the best method. This ensures efficient material removal, tool paths, and manufacturing efficiency for their projects.

Applications of CNC Milling and Turning

CNC milling and CNC turning are key in many industries. They help make precise parts for aerospace, cars, medical tools, and more. These methods are vital for creating high-quality, complex items.

Aerospace and Automotive Components

CNC milling and turning are crucial in aerospace and automotive. They make important parts like engine pieces and airframe structures. These methods work with many materials, from light alloys to strong steels.

This is why they’re vital for making high-performance parts for cars and planes.

Medical Devices and Industrial Machinery

In medicine, CNC milling and turning are used for special tools and prosthetics. They help make precision components for patient care. For industrial machinery, these techniques create custom parts with exact fits. This ensures machines work well in many manufacturing industries.

“The versatility and precision of CNC milling and turning have made them essential tools in modern manufacturing, enabling the production of critical components across a diverse range of industries.”

Shixinproto’s Precision CNC Services

At Shixinproto, we’re proud of our custom machining solutions for complex projects. Our team uses the latest CNC technology. This ensures top-notch precision and quality in all our work.

Tailored Milling and Turning Solutions for Complex Projects

Need intricate milled components or precision-turned parts? Shixinproto can make it happen. Our CNC machines handle a variety of projects, from aerospace to medical devices. We use advanced equipment and know-how to meet our clients’ high standards.

High-Quality Machining with Industry Expertise

Shixinproto’s expertise is key to our quality promise. Our team knows CNC machining inside out and follows strict quality checks. You can count on us for rapid prototyping, small batches, or large-scale production.