In today’s fast-paced manufacturing world, CNC milling and CNC milling centers are key players. They are essential for making precise parts. Knowing the differences between them is vital for manufacturers who want to improve their work and stay competitive. This article will dive into the main differences between CNC milling and CNC milling centers. We’ll look at their special features and uses in CNC machining, precision manufacturing, and industrial automation.

What is CNC Milling?

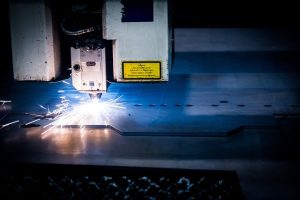

CNC milling is a way to make parts by removing material from a workpiece. It uses a computer to control the machine tool. This method is used in many fields like aerospace and automotive to make complex parts accurately and quickly.

Features of CNC Milling Machines

CNC milling machines have advanced features for precise material removal. They include:

- Computer numerical control (CNC) system to manage the machine’s movements and operations

- Spindle to hold and rotate the cutting tool

- Tool changer to automatically swap out different cutting tools during the milling process

- Coolant system to keep the cutting tool and workpiece cool during operation

- Precision linear and rotary axes to allow for complex part geometries

Typical Applications of CNC Milling

CNC milling is used in many industries. It’s great for making:

- Aerospace components, such as aircraft parts and helicopter rotor blades

- Automotive parts, including engine blocks, transmission components, and structural frames

- Medical devices, like prosthetic limbs and surgical implants

- Molds and dies for injection molding and die casting processes

- Precision parts for industrial machinery and equipment

The use of subtractive manufacturing, material removal, and milling operations in CNC milling makes it perfect for creating complex parts. It also relies on advanced CNC programming skills.

What is a CNC Milling Center?

A CNC milling center is a top-notch machine that goes beyond the usual CNC milling machine. It has special features for making complex parts and components with high precision. These machines can handle multi-axis machining, which is key for intricate designs.

Features of CNC Milling Centers

CNC milling centers stand out with their advanced features. These include:

- Multi-axis machining for complex shapes and five-sided work

- Integrated tooling systems for quick tool changes

- High-speed machining for faster work and less time needed

- Advanced CNC controls for better programming and monitoring

Advantages of CNC Milling Centers Over Milling Machines

CNC milling centers have big advantages over traditional CNC milling machines. These are:

- They work faster and more efficiently with automated tool changes and high-speed machining

- They offer better precision and accuracy for complex parts

- They can handle a wider range of workpiece sizes and materials

- They reduce setup time and improve workflow with integrated tooling systems

These benefits make CNC milling centers essential in today’s manufacturing world. They help meet the growing need for complex, high-quality parts. By using these machines, manufacturers can make their processes better, improve product quality, and stay ahead in the market.

Key Differences Between CNC Milling and CNC Milling Centers

CNC milling and CNC milling centers are both key in precision manufacturing. Yet, they have different features that affect how well they work and what they can do.

Tool Changing Capabilities

CNC milling machines usually have only a few tool slots, from 8 to 20. This means tools must be changed by hand, which can slow things down. CNC milling centers, however, have automated tool changers. They can hold up to 200 tools or more, making changes quick and easy.

Automation in CNC Milling Centers

CNC milling centers are more automated than traditional CNC milling machines. They use pallet systems for unattended operation, boosting production efficiency. These systems can load, unload, and position workpieces on their own. This reduces the need for manual work and improves multi-tasking capabilities.

Applications of CNC Milling vs. CNC Milling Centers

- CNC milling machines are great for making small-to-medium parts and for low-volume production. They are flexible and adaptable, even without high-speed automation.

- CNC milling centers, however, are best for high-volume, complex projects. They need automated tool changers and big pallet systems to be really efficient.

| Feature | CNC Milling | CNC Milling Center |

|---|---|---|

| Tool Changing Capabilities | Limited (8-20 tools) | Automated, up to 200+ tools |

| Automation Level | Manual tool changes | Pallet systems, automatic loading/unloading |

| Typical Applications | Small-to-medium parts, low-volume production | High-volume, complex manufacturing |

Shixinproto CNC Machining Services for Complex Projects

At Shixinproto, we’re proud to handle tough manufacturing tasks. Our CNC machining services use the latest tech to meet our clients’ high standards. We offer custom CNC solutions for precision prototype manufacturing and specialized precision engineering.

We understand the latest in CNC milling and CNC milling centers. This lets us bring your complex ideas to life. Our services cover many industries, like aerospace, automotive, medical, and industrial equipment. You can count on Shixinproto for quality and performance, no matter the project size or complexity.

Working with Shixinproto means you get our expertise and cutting-edge resources. We’re always innovating to stay ahead in the industry. See how our custom CNC solutions can make your manufacturing dreams come true.