In the world of modern manufacturing, CNC milling and CNC turning are key processes. Knowing the differences between them is important for choosing the right method for your project. This article will help you understand the unique features and benefits of each, guiding you in making the best choice for your needs.

CNC machining is a vital part of modern manufacturing. It uses computer-controlled tools to shape raw materials into precise parts. Whether you’re making a small prototype or a large batch, understanding CNC milling and CNC turning is essential. This knowledge will help you pick the best option for your projects.

What is CNC Milling?

CNC milling is a method that uses multi-axis machining to remove material. It shapes, drills, and carves complex shapes with great precision. This process is used in many industries, from aerospace to automotive.

Process and Key Features of CNC Milling

The CNC milling process uses a computer to control the cutting tools. It moves them along multiple axes. This makes it possible to create detailed parts with high accuracy.

Key features of CNC milling include:

- Multi-axis capabilities for producing complex geometries

- Automated material removal for increased efficiency

- Exceptional precision and repeatability

- Ability to work with a wide range of materials, from metals to plastics

Best Uses for CNC Milling Machines

CNC milling machines are great for many uses. They are versatile and used in various industries. Some of the best uses include:

- Prototyping and small-batch production of custom parts

- Manufacturing of complex components with tight tolerances

- Machining of materials like aluminum, steel, and titanium

- Production of intricate molds and dies for injection molding

- Fabrication of medical devices and implants

CNC milling is valuable for businesses. It allows for complex designs and works with many materials. This makes it a key tool for product design and manufacturing.

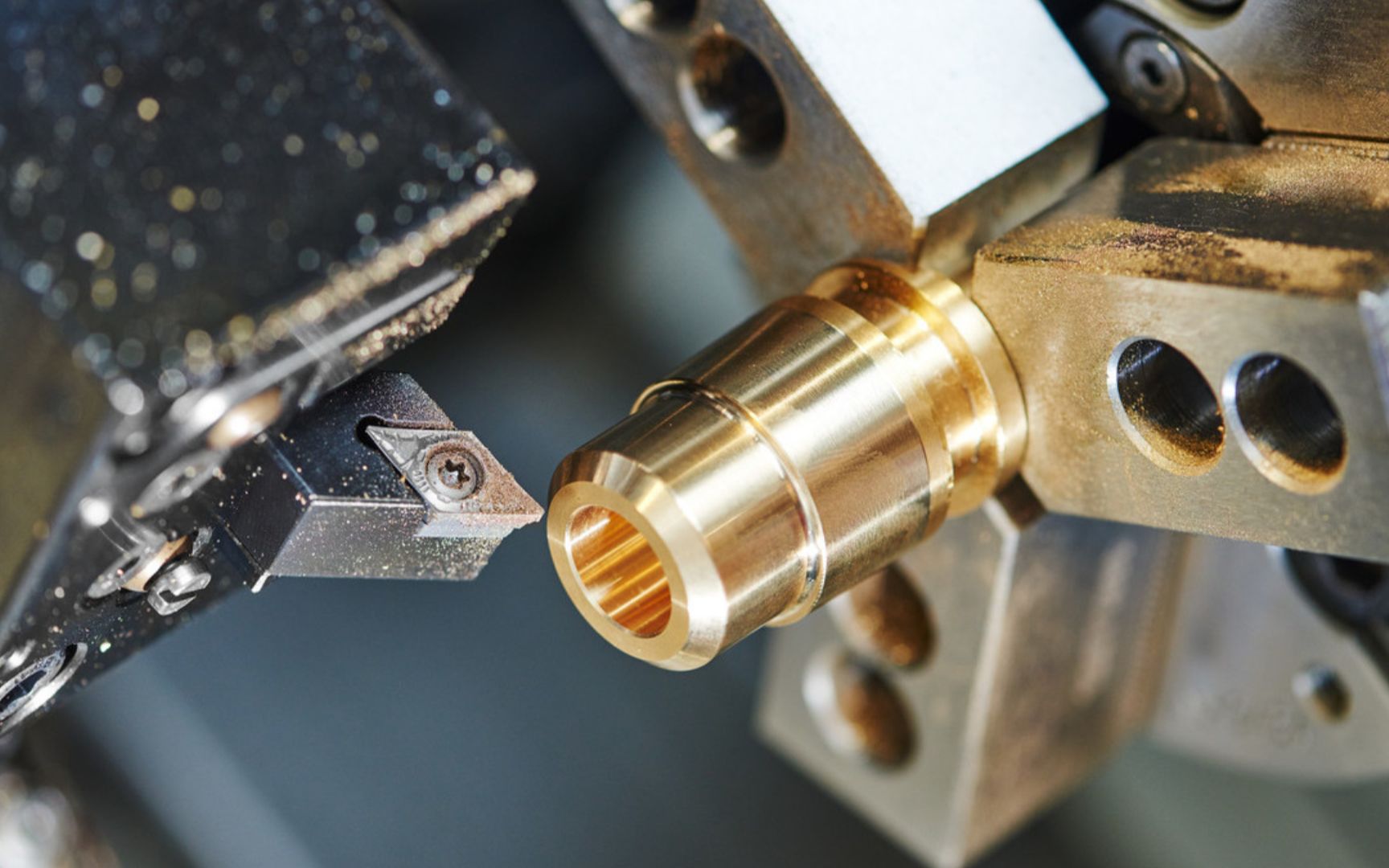

What is CNC Turning?

CNC turning is a machining method that rotates a workpiece while cutting away material. This creates cylindrical shapes. It’s great for making parts like shafts, gears, and other round components.

How CNC Turning Works

The workpiece is held in a chuck or collet and spins at a set speed. A cutting tool, like a lathe tool, moves along the workpiece’s axis. This removes material to shape the part.

The cutting tool’s movement and the workpiece’s rotation are controlled by a CNC system. This ensures accurate and consistent results.

CNC Turning: Ideal for Creating Cylindrical Shapes

- CNC turning is perfect for making many cylindrical parts, including:

- Shafts and axles

- Gears and pulleys

- Bushings and bearings

- Valves and fittings

- Piston components

- Cylindrical parts are ideal for CNC turning because of their rotational symmetry. This makes them easy to shape with high precision.

- CNC turning is especially good for lathe operations that need cylindrical components with rotational symmetry.

Using CNC turning, manufacturers can make many cylindrical parts accurately and affordably. This makes it a valuable tool in various industries.

CNC Milling vs CNC Turning: Key Differences

CNC milling and CNC turning are key in precision manufacturing. They both have great machining capabilities. Knowing their unique benefits helps you choose the right one for your needs.

Applications: When to Use CNC Milling vs CNC Turning

CNC milling is best for making complex, three-dimensional parts. It’s great for parts with many shapes and details. On the other hand, CNC turning is perfect for making round parts like shafts and gears.

Speed and Efficiency in CNC Milling and Turning

CNC turning is often faster and more efficient than CNC milling. But, CNC milling is better for small, detailed parts in small to medium batches. It’s versatile and can handle complex features.

Precision and Material Compatibility

Both CNC milling and turning are very precise. CNC milling might have a slight edge in material versatility. It works with a wide range of materials, including metals, plastics, and composites. CNC turning mainly works with metals.

| Feature | CNC Milling | CNC Turning |

|---|---|---|

| Applications | Complex, 3D parts with intricate features | Cylindrical or rotational parts, such as shafts, gears, and bushings |

| Production Efficiency | Versatile for small, complex parts in low to medium volumes | Generally higher efficiency for larger production runs |

| Precision | Highly precise, capable of tight tolerances | Highly precise, capable of tight tolerances |

| Material Compatibility | Wide range of materials, including metals, plastics, and composites | Primarily used for metallic workpieces |

Knowing the strengths of CNC milling and CNC turning helps you choose the best process. This ensures you meet your production efficiency, material versatility, and machining capabilities needs.

Shixinproto Custom CNC Solutions for Your Projects

At Shixinproto, we know every project is different. We offer custom CNC milling and turning solutions for various industries. Our skilled team can help bring your ideas to life, whether it’s precision parts or prototypes.

We have the latest CNC equipment and know-how in milling and turning. We can tackle a wide range of tasks, from aerospace parts to medical shapes. Shixinproto is your go-to for custom manufacturing, CNC services, and prototype development.

We work closely with our clients to ensure top-notch quality and detail. Our focus on innovation keeps us leading the industry. Trust Shixinproto to turn your ideas into real, high-quality solutions.