In today’s fast-paced world, efficient supply chain management is key to success. CNC (Computer Numerical Control) machining has changed manufacturing and improved supply chain operations. It offers many benefits that boost supply chain efficiency, helping businesses grow and succeed.

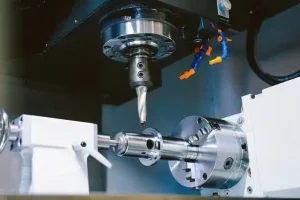

CNC machining uses computer-controlled machines to make precise parts and components. This technology helps businesses make their manufacturing processes better, improve product quality, and meet market demands faster. We’ll look at how CNC machining services make supply chains more efficient and give businesses a competitive edge.

The Role of CNC Machining in Supply Chain Management

CNC machining has changed the game in supply chain management. It’s now a key part of how businesses manage production and inventory. By using CNC machining, companies can improve their operations and stay ahead of the competition.

Benefits of CNC Machining in Modern Supply Chains

CNC machining brings many benefits to modern supply chains. It’s precise, fast, and flexible. These qualities help streamline production, cut down on lead times, and boost overall efficiency.

Improving Flexibility and Speed in Production

CNC machining makes production faster and more flexible. CNC machines can quickly change to meet new product needs. This quickness is key in today’s fast world, where being able to adjust quickly is a big plus.

CNC Machining and Just-in-Time Manufacturing

CNC machining fits perfectly with just-in-time (JIT) manufacturing. It produces parts and components just when they’re needed. This approach reduces inventory, cuts costs, and keeps materials flowing smoothly. It’s a key part of successful JIT strategies, leading to better efficiency and quickness.

As supply chain management keeps evolving, CNC machining’s role is more important than ever. It helps businesses improve flexibility, speed, and just-in-time production. This way, companies can make their supply chains better, stay competitive, and succeed in the long run.

How CNC Machining Improves Supply Chain Resilience

In today’s fast-paced business world, being resilient in the supply chain is key. CNC machining helps a lot by allowing companies to make things themselves. This cuts down on wait times and lessens the need for outside suppliers.

In-House Production and Reduced Lead Times

Companies can make things themselves with CNC machining. This means they don’t have to wait on others. It also lets them control the making process better, so they can get products to customers fast.

This way, businesses can quickly meet market needs and handle unexpected problems in the supply chain.

Reducing Dependency on External Suppliers

Using CNC machining helps companies not rely so much on outside suppliers. This makes them less vulnerable to supply chain problems. By making parts and pieces themselves, they can use fewer outside materials.

How CNC Machining Enhances Product Consistency and Quality

CNC machining makes sure products are the same and of high quality. This is good for the supply chain’s strength. CNC machines can make the same part over and over, which means fewer mistakes and happier customers.

This keeps the brand’s good name and keeps customers coming back, even when supply chain issues arise.

| Benefit | Description |

|---|---|

| In-house production | Reduces reliance on external suppliers and enables faster response to market changes. |

| Reduced lead times | Shortens the time required to deliver products to customers, improving responsiveness. |

| Consistent product quality | Ensures a high level of quality and reliability, maintaining customer satisfaction. |

Adding CNC machining to their plans helps businesses stay strong and competitive. It’s all about making things themselves, getting things done faster, and making sure products are always good. CNC machining is a big help in making supply chains better.

Optimizing Your Supply Chain with CNC Machining

In today’s fast-paced business world, optimizing your supply chain is key. CNC machining services offer a versatile solution to streamline your supply chain. This unlocks new efficiencies for your business.

Streamlining Material Sourcing with CNC Services

CNC machining helps streamline material sourcing. It uses precision and flexibility to reduce lead times and inventory. This ensures a consistent supply of high-quality components.

This makes your supply chain more agile and responsive. You can adapt quickly to changing market demands.

Utilizing CNC Machining for Rapid Prototyping and Production

CNC machining is also key for rapid prototyping and production. It allows for quick and cost-effective creation of custom parts. This speeds up product development cycles.

This agility is crucial in today’s fast-changing business world. Being able to respond quickly to customer needs can be a game-changer.

Minimizing Waste and Improving Sustainability

Sustainability is a big concern for businesses today. CNC machining helps minimize waste and improve environmental impact. It uses precise control and efficient material use.

This reduces material waste, energy consumption, and environmental footprint. You can maintain high-quality standards while meeting production goals.

By using CNC machining services, you can unlock many benefits. These include streamlined material sourcing, rapid prototyping, and improved sustainability. As you navigate the business world, consider CNC technology’s power to optimize your supply chain.

Case Studies: CNC Machining in Action Across Industries

We explore how CNC machining changes industries. It’s not just about making things faster and more precise. It’s about making a real difference in how things are made.

From making cars to making planes, CNC machining is key. It helps make supply chains better and boosts new ideas.

Automotive Industry: Streamlined Production and Inventory Control

A big car maker teamed up with a CNC expert. They made their supply chain better. Now, they can make cars faster and with less waste.

This change helped them save money and make customers happier. It’s a win-win for everyone.

Aerospace: Enhancing Speed and Precision in Manufacturing

The aerospace world is all about quality. CNC machining helps them make things faster and more precise. This means they can make parts quicker and with better quality.

It’s a big deal for them because it keeps them competitive. They can keep up with the latest trends.

Medical Devices: Accelerating Innovation with CNC Machining

CNC machining is a game-changer for medical devices. A top maker of surgical tools uses it to make new ideas happen fast. They can quickly try out new designs and make changes.

This means they can meet patient needs faster. It’s all about making medical devices better and faster.

| Industry | CNC Machining Impact | Key Outcomes |

|---|---|---|

| Automotive | Streamlined production, improved inventory control | Greater flexibility, reduced waste, cost savings |

| Aerospace | Enhanced speed and precision in manufacturing | Accelerated production, higher quality standards |

| Medical Devices | Accelerated innovation through rapid prototyping | Faster response to evolving market needs |

These stories show how CNC machining changes things. It makes supply chains better and helps new ideas grow. It’s changing how we make things in many fields.

Why Choose Shixinproto for CNC Machining Services to Optimize Your Supply Chain

Shixinproto is your go-to for CNC machining services to boost your supply chain. We have years of experience and a focus on quality. Our services can make your production smoother and improve your supply chain’s efficiency.

We’re proud of our advanced CNC equipment and skilled team. They handle everything from metal fabrication to quick prototyping. This means we can provide top-notch parts and components for any project.

What makes us special is our commitment to making our customers happy. We listen to your supply chain problems and create solutions just for you. Whether you’re in automotive, aerospace, or medical devices, Shixinproto can help. We’re here to make your business succeed.