Home » CNC Machining Service » 5 Axis CNC Machining Service

5 Axis CNC Machining Service

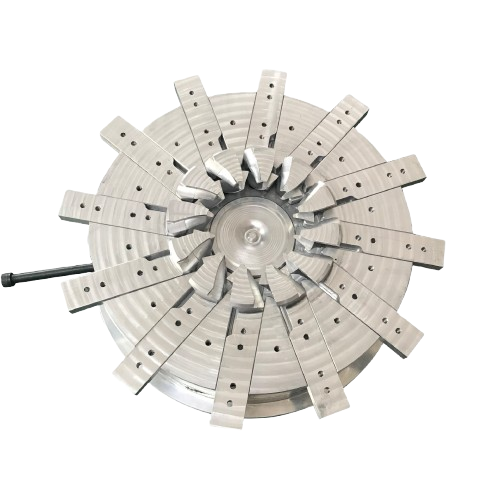

Shixinproto provides high-precision five-axis CNC machining parts services, suitable for complex and difficult parts processing, ensuring accuracy and high-quality surface treatment.

- 3/4/3+2/5 Axis CNC machining

- Competitively priced Save 30%

- Real factory welcome to visit

- No MOQ

Our 5 Axis CNC Machining Parts Capabilities

Shixinproto offers cutting-edge 5-axis CNC machining services, providing precision manufacturing for complex parts with high accuracy and efficiency. Our advanced machinery and experienced team ensure that even the most intricate designs are produced with tight tolerances and minimal lead times. Whether for aerospace, automotive, medical, or electronics applications, our 5-axis capabilities are designed to meet the diverse and demanding requirements of modern industries.

| Capability | Specification | Our Advantage |

|---|---|---|

| Maximum Part Size | 800mm (Diameter) x 2200mm (Length) | Ability to handle large, complex parts |

| Precision Tolerance | ±0.005mm to ±0.01mm | Ultra-tight tolerances for high-precision parts |

| Materials Supported | Aluminum alloy, stainless steel, titanium, plastic, composite materials, etc. 99+ materials | Wide material selection for versatile production |

| Max Part Weight | Up to 200kg | Can machine heavy-duty parts with high stability |

| Cutting Speed | Up to 10,000 RPM | High-speed cutting to ensure efficiency |

| Surface Finish | Ra 0.8 to Ra 1.6 | Excellent surface quality for both functional and aesthetic parts |

| Complexity of Parts | Intricate geometries, undercuts, deep holes, multi-axis machining | Expertise in manufacturing complex designs that are challenging for traditional methods |

| Turnaround Time | 5-7 days for prototypes, 15-30 days for production orders | Fast prototyping and efficient production timelines |

| Industry Applications | Aerospace, Automotive, Medical, Electronics, Industrial Components | Serving diverse industries with tailored solutions |

CNC Machining Parts Materials & Finishes

- Aluminum

- Stainless steel

- Steel

- Titanium

- Bronze

- Brass

- Copper

- Zinc

- Iron

- Customizable

- As Machined

- Bead Blasting

- Sand Blasting

- Painting

- Anodizing

- Plating

- Burnish

- Chromate

- Customizable

about our culture

Leading the way in repair solution

Shixinproto specializes in high-precision 5-axis CNC machining, offering custom parts production with tight tolerances and superior finishes. With 14 years of experience and advanced machinery, we handle a wide range of materials and provide additional services like anodizing, electroplating, and heat treatment. Our ISO9001-certified factory ensures top-quality production for both small-batch and large-volume orders, serving industries worldwide.

Receive expert guidance and customized solutions to ensure the success of your project from concept to completion.

Send us an email

Comparative Analysis: 5-Axis versus 3+2 Axis CNC Machining

| Feature | 5-Axis CNC Machining | 3+2 Axis CNC Machining |

|---|---|---|

| Motion and Flexibility | Full simultaneous movement on five axes, offering complete flexibility for complex geometries | Movement limited to three linear axes with two rotational axes fixed, not simultaneous |

| Complexity of Parts | Ideal for highly complex and intricate parts requiring multiple angles, undercuts, and fine details | Best suited for simpler parts or those that can be repositioned into set angles |

| Precision and Tolerances | Provides ultra-precise machining with tight tolerances (±0.005mm) for high-end applications | Precision is still good, but not as tight as 5-axis machining (typically ±0.01mm to ±0.02mm) |

| Setup Time | Fewer setups required due to simultaneous cutting from multiple directions | More setups needed due to part repositioning between cuts |

| Machine Cost and Complexity | Higher cost and more complex due to simultaneous multi-axis control | More affordable and less complex, but with limitations in part complexity |

| Material Handling | Can machine more complex materials and shapes in one setup, reducing handling time | Can handle standard materials and parts, but may require additional setups for complex shapes |

| Production Efficiency | High efficiency for complex and detailed parts, reduced handling and tool changes | Faster for simple parts, but less efficient for parts with complex geometries |

| Tool Wear and Surface Finish | Reduced tool wear and better surface finish due to fewer tool changes and continuous cutting | May require more frequent tool changes and adjustments, potentially leading to a less optimal finish |

Choosing Between 5-Axis and 3+2 Axis Machining

The choice between 5-axis and 3+2 axis machining ultimately depends on the complexity and requirements of your parts:

Choose 5-Axis CNC Machining if:

You require high-precision parts with complex geometries, undercuts, or multi-directional features.

Your project involves tight tolerances (e.g., ±0.005mm) or intricate details such as those found in aerospace, medical, or high-performance industries.

You aim to reduce setup times and increase efficiency for intricate, multi-dimensional parts.

Choose 3+2 CNC Machining if:

Your parts have simpler geometries and can be machined using a fixed rotational setup.

ou are working with cost-sensitive projects and need an affordable alternative with less complexity.

You need faster setup times and are not as concerned with high-end, multi-directional part features.

Ready to receive a quote?

Simply fill out our inquiry form, and we’ll get back to you within 24 hours. The more details you provide, the more accurate and tailored your quote will be. Don’t hesitate – get started today and let us help you with your project!