Home » CNC Machining Service

CNC Machining Service

From prototype to perfection, high-quality CNC machining to meet complex needs, your trusted precision machining partner.

- 3/4/3+2/5 Axis CNC machining

- Competitively priced Save 30%

- Real factory welcome to visit

- No MOQ

Our CNC Machining Capabilities

If you are looking for a reliable supplier of quality CNC machined metal parts, your search ends here. We offer the solution that best suits your requirements, namely 5-axis CNC milling and turning, which allows us to provide both complex and simple parts with quality requirements and very tight tolerances, we are able to handle highly difficult geometries and very high specificity parts in very short turnaround times.

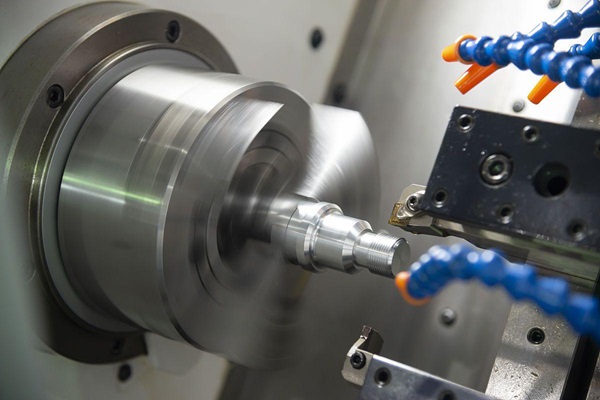

Used to achieve multi-plane machining of complex parts, ensuring high precision and detailed surface treatment.

- Lead time as fast as 3 day

- Tolerances down to ±0.002mm

- Specializing in complex geometries

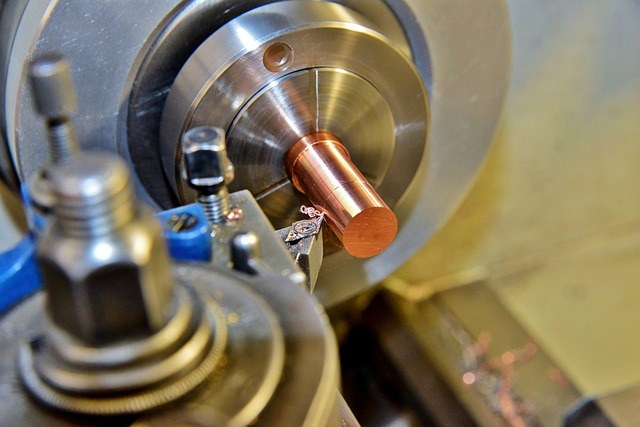

Suitable for efficient machining of cylindrical parts, achieving precise dimensions and smooth surfaces.

- ISO 9001:2015

- 55+ suraface finishes

- Tolerances down to ±0.002mm

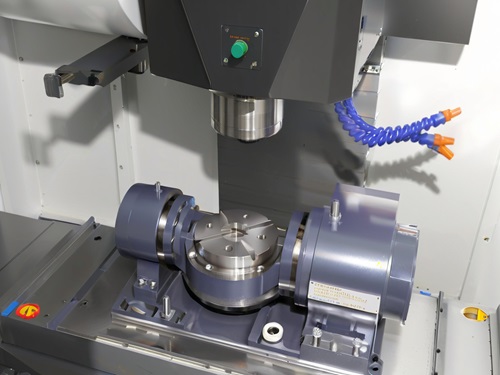

Can process complex geometric shapes, improve machining efficiency and high precision standards.

- ISO 2768 and ISO 286

- 5/3+2 axis cnc machining

- 60+ production-grade materials

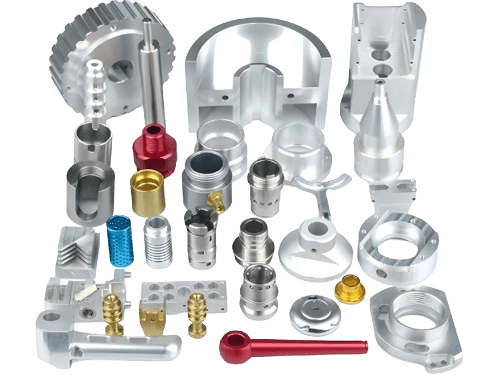

CNC Machining Parts Materials & Finishes

- Aluminum

- Stainless steel

- Steel

- Titanium

- Bronze

- Brass

- Copper

- Zinc

- Iron

- Customizable

- As Machined

- Bead Blasting

- Sand Blasting

- Painting

- Anodizing

- Plating

- Burnish

- Chromate

- Customizable

about our culture

Leading the way in repair solution

Varius quam quisque id diam vel. Sed nisi lacus sed viverra tellus in. Viverra aliquet eget sit amet tellus cras adipiscing enim. Est velit egestas dui id ornare arcu odio ut sem. Tristique senectus et netus et malesuada. Nunc.

Our goal:

"Speed and accuracy provider"

Receive expert guidance and customized solutions to ensure the success of your project from concept to completion.

Send us an email

Why Choose Shixinproto Custom CNC Machining Service

CNC Milling Tolerances

| Parameter | Specification |

|---|---|

| General Tolerances | Metals: ISO 2768-m, Plastics: ISO 2768-c |

| Tolerances | ±0.001 inches (±0.0254 mm) |

| Min Wall Thickness | 0.5 mm (0.02 inches) |

| Min End Mill Size | 0.5 mm (0.02 inches) |

| Min Drill Size | 1 mm (0.04 inches) |

| Maximum Part Size | CNC Milling: 4000 × 1500 × 600 mm (157.5 × 59.1 × 23.6 inches) CNC Turning: 200 × 500 mm (7.9 × 19.7 inches) |

| Minimum Part Size | CNC Milling: 5 × 5 × 5 mm (0.2 × 0.2 × 0.2 inches) CNC Turning: 2 × 2 mm (0.08 × 0.08 inches) |

| Production Volume | Prototyping: 1-100 pcs Low Volume: 101-10,000 pcs High Volume: Above 10,001 pcs |

CNC Machining Equipment

It has more than 50 advanced CNC processing equipment such as four-axis and five-axis CNC machine tools, precision CNC lathes, large super-precision grinders, and more than ten precision testing equipment such as three-coordinate measuring machines, laser scanners, and image measurement systems.

Service Advantages

- One-to-one quotation: upload 2D or 3D design, get quotation feedback within 24 hours, professional engineers analyze the design to prevent misunderstanding, and communicate to provide affordable prices.

- Fast delivery: advanced equipment and professionals ensure fast delivery, and order priority is set according to demand and complexity.

- High-quality parts: responsible for rigorous treatment of materials and other links, ensuring the quality from prototype to production parts, and carefully checking before delivery.

- Instant communication: customers have technical support contact from quotation to delivery, and problems are quickly fed back to ensure customer satisfaction.

Ready to receive a quote?

Simply fill out our inquiry form, and we’ll get back to you within 24 hours. The more details you provide, the more accurate and tailored your quote will be. Don’t hesitate – get started today and let us help you with your project!

Are you a trader or manufacturer?

What materials do you use for manufacturing heat sinks?

Can I visit your factory?

What is the maximum size of heat sinks you can manufacture?

Do you provide thermal testing for heat sinks?

How can I get a quote for my heat sink project?

Guide to Selecting the Right China CNC Machining Manufacturer

1. Understand the Needs: Clarify Your CNC Processing Requirements

Usually, before asking for a quote from a cnc machining manufacturer, customers need to clarify the technical requirements of their products, such as the choice of processing materials, the processing accuracy of the product, the tolerance range, surface treatment requirements, etc. If the requirements are clear, it is easier to know the exact quantity to purchase from the manufacturer, thereby ensuring that the purchased quantity matches the quantity of products sold. Therefore, this helps to avoid quality problems or additional costs caused by insufficient technical accuracy and completeness. Therefore, one of the keys to the success of this cooperation is to ensure that the customer’s processing requirements are sufficient and accurate.

For demand confirmation, we have rich experience and will provide customers with professional demand analysis and attention, because we keep close communication with customers when we start designing to confirm every detail and produce customers’ products according to their needs.

We have a wide range of applicability in the selection of processing materials, including aluminum alloy, stainless steel, carbon fiber and other materials, with a processing accuracy of up to ±0.01 mm and a tolerance control range that can be strictly kept within ±0.01 mm. In terms of surface treatment, we can provide a variety of options such as anodizing, electroplating, polishing and sandblasting, and the surface roughness can be controlled within Ra0.6.

2. Investigate the capabilities and equipment of the manufacturer

The guarantee of product quality depends on the manufacturing equipment capabilities of the supplier. When inspecting suppliers, customers can ask whether the manufacturer has advanced CNC processing equipment (specifically four-axis/five-axis CNC machine tools, precision lathes, etc.), and whether the manufacturer’s processing equipment is diversified (such as CNC turning and grinding, CNC drilling and milling, with micron-level accuracy?). These aspects have improved the processing accuracy of complex products and can bring more flexible product specifications according to the diverse needs of users.

We have more than 50 advanced CNC processing equipment such as four-axis and five-axis CNC machine tools, precision CNC lathes, large ultra-precision grinders, etc., which can effectively process high-precision complex parts. Various supporting production capabilities can complete from prototype to mass production. Strong technical and equipment reserves ensure that our company can respond quickly and ensure project quality.

3. Evaluate the manufacturer’s qualifications and certifications

For customers, ensuring that cnc machining suppliers have the right qualifications and certifications (such as ISO 9001 and IATF 16949 in the automotive industry, ISO 13485 in the medical industry) is crucial to ensure that the production process and product quality meet standards, thereby minimizing the possibility of ending up with one in seven substandard products.

We fully comply with international standards and have passed the ISO 9001 quality management system certification, as well as industry certifications such as IATF 16949 and ISO 13485, to ensure that all types of products meet the quality and safety requirements of the international market. We have also set up a professional quality control team in each production link, from the source of raw materials to the final product terminal, strictly reviewing, participating and controlling, ensuring that each link is not only strictly tested, but also strictly approved, providing full-process quality assurance cooperation.

4. Quality Assurance: Key Quality Testing Process

The testing process is the basis for product qualification. Buyers should always choose manufacturers with advanced testing equipment and strict QC (quality control) processes, and make sure they have testing equipment such as CMM (coordinate measuring machine), laser scanner, image measurement system, etc., so as to strictly ensure the dimensional accuracy, tolerance and product requirements according to the customer’s quality requirements.

First, we have a full set of quality inspection systems and more than ten precision inspection equipment, such as coordinate measuring machine, laser scanner, image measurement system, etc. Secondly, we have a group of excellent quality control teams who carry out strict precision measurement to ensure that every order can satisfy customers. In addition, we will provide BOA for each batch of production, so that customers can check our report at any time, so that they can know whether the quality meets the requirements.

5. MOQ (minimum order quantity) and mass customization capabilities

The diversity of customer needs leads to different types of order quantities. If you want to find a manufacturer that suits you, it is very important to consider its MOQ (minimum order quantity) and mass production capabilities. For customers who produce small batches, the flexibility of the supplier is especially important, and if your order volume is large, the supplier’s mass production capacity is especially important.

We provide relatively flexible MOQ policies by product category and by piece. Our large-scale production capacity allows small-batch trial production and synchronous response to different scales of demand, from prototype to mass production. We can adjust the production process and production equipment platform to adapt to different production scales according to different order sizes, breaking through the previous bottleneck.

6. Geographical location and logistics support

The location of the cnc machining manufacturer directly affects the convenience of export logistics. It is best to choose a factory close to the port because the transportation method will be simpler. Coastal cities (Shenzhen, Dongguan, Shanghai) have developed logistics facilities, fast product shipments, and shortened delivery time.

We are in Shenzhen, and there are major ports and airports nearby. The geographical location is superior, providing convenient export logistics support for the factory, docking and cooperating with many overseas logistics companies, providing customers with safe and efficient transportation methods and full professional support services for product exports to the market.

7. Communication and customer service capabilities

Efficient communication is the key to the successful completion of a cooperation project. For cross-border cooperation, the smoothness of communication is even more important. If the manufacturer is equipped with a professional project organization and has professional English communication skills, the logistics effect will be greatly improved. In particular, it is necessary to ensure that the supplier has a professional project manager and an English customer service team, so that not only can the customer’s problems be fed back in real time, but also the supplier’s professional response can be obtained in time.

Our strong expertise in cross-border projects enables us to provide first-class project management for our customers. At the same time, we have English-speaking customer service staff who are on call at any time and can respond to customer needs in real time. For each project, we provide a dedicated project manager so that our customers can get full support from demand confirmation to production and delivery. This enables customers to obtain production status and technical support in a timely manner, help deal with any unexpected events, and make the project go smoothly.

8. Transparent Quotation and Contract Terms

Quotations need to be transparent in terms of cooperation. If customers want to choose a supplier to cooperate, they must ensure that the supplier’s quotation is clear, including material costs, processing fees and surface treatment fees, packaging and transportation fees, etc. In addition, the contract terms also need to be clear to avoid disputes caused by unclear costs.

We adhere to the principle of transparent quotation, all costs are transparent, including each production cost and transportation cost, to avoid additional expenses for customers. Our contract signing is detailed and transparent, involving delivery time, guarantee, breach of contract, etc., focusing on the rights and interests of both parties, so that customers can be worry-free and not afraid of any form of restraint.

9. Sample and small batch trial production

Before signing a large order, conducting sample or small batch test production can help customers verify the quality and technical level of the manufacturer. Through sample testing, customers can confirm the supplier’s production capacity and ensure that the quality of the final product meets expectations, thereby reducing the risk of cooperation.

We also provide sample and small batch production sample services. If you have doubts about the quality or appearance of the product, we are willing to provide you with sample and small batch production services so that you can view the appearance of the product and check the quality at the same time.

For the sample production process, we will proceed in multiple times until it meets your expectations. By taking this step, we will help you further optimize the design and ensure that every detail of the product meets the standards. The flexible sample production process is the guarantee of the correct decision we provide to our customers.

10. Visit the factory or use a third-party inspection service

In order to quickly understand the cnc machining manufacturer’s production environment and strength, it is recommended that customers visit the factory in person or hire a third-party inspection service for inspection or audit (also known as factory audit) to understand the factory’s production capacity and quality control level according to customer requirements.

We welcome customers to visit our factory at any time to feel the atmosphere of the production environment, the condition of the instruments, and the management process. At the same time, we provide inspection reports to facilitate customers to return to the office to evaluate our strength in production and quality assurance systems. We maintain a transparent and trustworthy attitude and hope to establish a long-term cooperative relationship.

We will provide customers with one-stop processing services for CNC processing with advanced equipment, high-standard quality inspection, large-scale production capacity and transparent cooperation processes. Customers who choose us can not only enjoy cost-effective processing solutions, but also reliable project management support and perfect after-sales service. With the support of our professionalism, customers can evaluate suitable manufacturing solutions and cooperate in the long-term delivery of high-quality products.