CNC machine shops are key in precision manufacturing. They help turn ideas into reality. Whether you need custom parts, detailed components, or big production runs, the right CNC shop is vital. This guide will show you the CNC world, its services, what to look for, and how to pick the best partner for your project.

CNC machining helps many industries, like aerospace and automotive. Each industry has its own needs. Knowing what different CNC shops can do helps you find the perfect match for your project. This ensures a great partnership.

Start your journey into the CNC machine shop world. Here, precision, quality, and customer happiness drive top-notch manufacturing solutions.

What is a CNC Machine Shop?

A CNC (Computer Numerical Control) machine shop uses advanced, computer-controlled machines to make parts and components. These modern facilities lead the CNC manufacturing world. They offer precise and efficient automated production.

Overview of CNC Machine Shops

CNC machine shops use top-notch technology like CNC milling machines and CNC lathes. This technology allows for making complex parts and customized products with high precision. It’s a step up from traditional manual machining methods.

Types of CNC Services Offered by Machine Shops

CNC machine shops provide a variety of services, including:

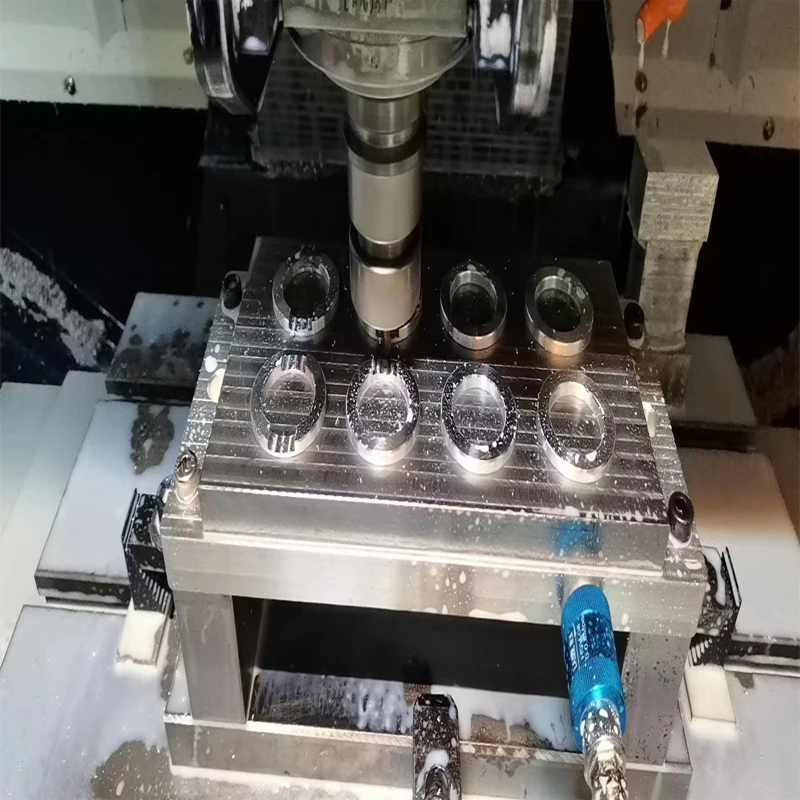

- CNC Milling: They use computer-controlled milling machines for precise part machining.

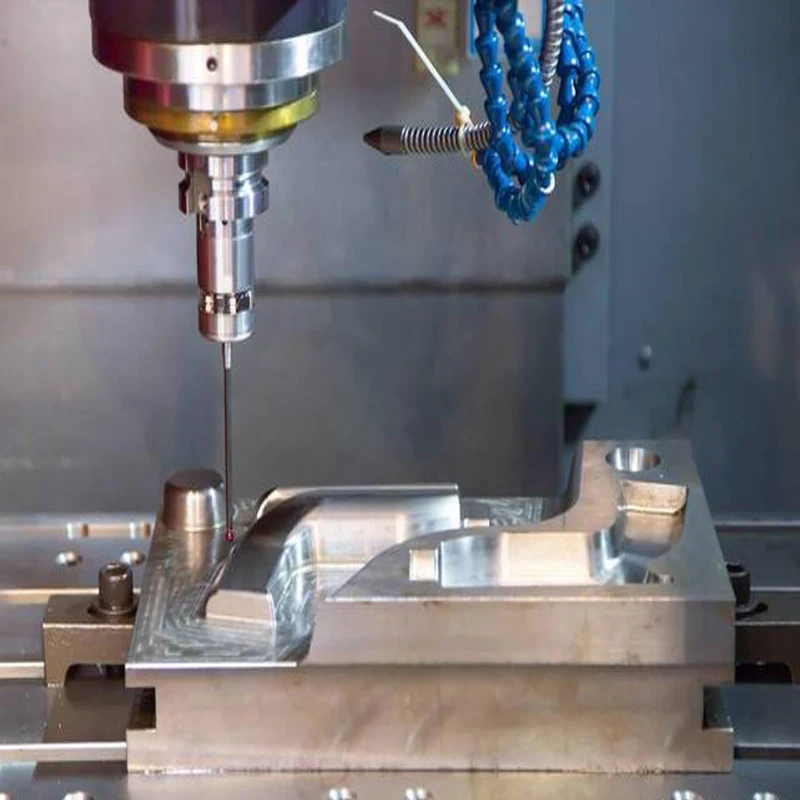

- CNC Turning: They use CNC lathes for high-performance machining of cylindrical parts.

- Custom CNC Fabrication: They create custom parts and components to meet specific needs.

- 3D Printing and Rapid Prototyping

- Precision Measurement and Inspection

- Design and Engineering Services

By using CNC manufacturing, these shops offer high-quality, efficient, and cost-effective solutions. They serve many industries, from aerospace and automotive to medical and consumer goods.

How to Choose the Right CNC Machine Shop for Your Project

Finding the right CNC machine shop is key for quality results and a smooth process. When picking a CNC shop, consider several important factors. These will help you make a good choice.

Key Factors to Consider When Selecting a CNC Shop

First, check the machining expertise and experience of the shop. Look for a shop with a good history of making precise parts and custom solutions. Also, make sure they have the right equipment capabilities for your project.

Other things to think about are how fast they work, if they’re cost-effective, and their quality control. Choose a shop that offers clear prices, reliable delivery, and strict quality checks. This will make you feel confident during the manufacturing process.

Questions to Ask a CNC Machine Shop Before Hiring

When looking at CNC machine shops, ask the right questions. This will help you see if they’re right for your project. Here are some questions to ask:

- What CNC machining services do you offer, and what are your specialties?

- Can you show me examples of similar projects you’ve done?

- What steps do you take to ensure quality in your work?

- How fast can you complete a project, and can you meet tight deadlines?

- How do you figure out costs for CNC machining services?

By doing your research and asking the right questions, you can find a CNC machine shop that meets your needs. They will help bring your project to life with precision, efficiency, and good value.

Types of CNC Machining Services Provided by Shops

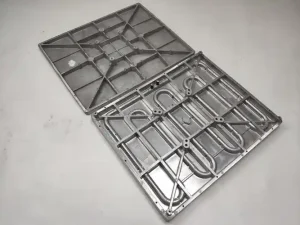

CNC machining offers a wide range of services. Shops can do CNC milling for precision and CNC turning for versatility. They also handle custom fabrication for complex projects with multi-axis machining.

CNC Milling Services

CNC milling shapes parts by removing material with rotating tools. It’s great for making detailed parts with tight tolerances. A skilled CNC milling shop can create complex designs.

CNC Turning Services

CNC turning makes cylindrical parts by rotating the workpiece. It’s perfect for parts with holes, grooves, and threads. CNC turning shops make precise components, from simple to complex parts.

Custom CNC Fabrication Services

For unique projects, CNC machine shops offer custom fabrication. They use multi-axis machining for complex shapes and materials. A skilled team can turn your ideas into reality, whether it’s a prototype or a small batch.

The Importance of Quality Control in CNC Machine Shops

In CNC machining, quality control is key. It makes sure parts are precise, reliable, and safe. CNC shops use strict checks and recognized certifications to ensure top results for their customers.

Quality Assurance in CNC Machining

CNC shops use many quality control steps. They do in-process inspections and final inspections to check parts. They also use statistical process control and coordinate measuring machines to keep an eye on production.

Certification Standards and What They Mean for You

Many CNC shops are ISO 9001 certified. This shows they follow quality management systems and keep improving. It means their quality control processes, inspection methods, and operations meet high international standards.

| Certification | What It Means |

|---|---|

| ISO 9001 | Ensures consistent and reliable production processes. |

| AS9100 | Meets aerospace-specific needs, for aviation, space, and defense. |

| IATF 16949 | Focuses on quality for the automotive industry, aiming for defect prevention and improvement. |

Choosing a CNC shop with strong quality control processes and certifications means you can trust their parts. This leads to a successful project.

CNC Machine Shops for Specific Industries

CNC machining is not the same for every industry. Each one has its own needs and needs special skills from CNC shops. Aerospace and automotive parts production are two areas that really need CNC shops’ precision and know-how.

CNC Machine Shops for Aerospace Manufacturing

Aerospace engineering is very demanding. It needs a lot of detail and can work with many materials, like aluminum and titanium. CNC shops for aerospace must be able to handle small details, do complex tasks, and keep quality high.

These CNC shops often have AS9100 certification. This shows they meet aerospace’s high standards. They also have skilled workers who can handle the complex parts for planes, satellites, and more.

CNC Shops for Automotive and Industrial Applications

In the automotive and industrial fields, CNC shops are key for making important parts. They work with many materials and need to keep quality high. They also have to meet tight standards.

Many CNC shops in these areas offer custom services. This lets them make special parts or prototypes for their clients. Being flexible and quick is crucial in these fast-changing industries.

| Industry | Key CNC Machining Requirements | Certifications Needed |

|---|---|---|

| Aerospace |

|

|

| Automotive and Industrial |

|

|

By knowing what each industry needs, CNC shops can be great partners. They can offer the precision, quality, and special skills that clients want.

Top CNC Machine Shops in Your Area

Finding the right CNC machine shop can be tough. You want quality and service. With some effort, you can find the best CNC shops near you.

Tips on Finding the Best Local CNC Machine Shops

- Ask your professional contacts for recommendations.

- Look up online reviews and portfolios of local CNC shops.

- Visit industry events to meet CNC shop reps.

- See if local CNC shops are part of a big manufacturing network.

Online CNC Services vs. Local Shops

Online CNC machining services are easy to use. But, local CNC machine shops have their own benefits. They know the local industry well and give you more personal service.

Choosing between online services and local shops depends on your project needs. Think about your timeline and how much you want to work with the shop. This will help you make the best choice for your project.

Why Choose Shixinproto for CNC Machining Services

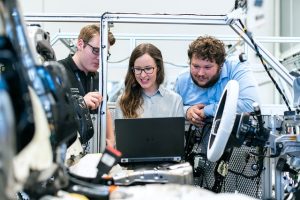

Shixinproto is a top choice for CNC machining. They have the latest equipment and a team of experts. They focus on quality and detail in every project.

Shixinproto is all about quality. They use the best CNC technologies and strict quality control. This ensures your parts are precise and accurate. They work with aerospace, automotive, and industrial sectors, delivering great results.

The team at Shixinproto is dedicated to making customers happy. They listen to what you need and offer solutions that go beyond your expectations. They are known for clear communication and quick delivery, making them a reliable partner for CNC machining services.