Torsion springs

- Extensive Material and Finish Options

- ISO 9001 Certified Torsion springs Manufacturer

At ShixinProto, we specialize in designing and manufacturing custom torsion springs that meet the unique needs of businesses across industries. Whether for automotive, aerospace, medical, or industrial applications, our torsion springs are crafted to provide reliable performance and durability.

We offer tailored solutions, with each spring designed to your exact specifications for load capacity, rotational angle, and material requirements. Our advanced CNC technology ensures high precision, while our extensive material options—such as stainless steel, carbon steel, and alloy steel—help enhance the strength and lifespan of your springs.

If you’re looking for a reliable partner to deliver high-quality torsion springs, contact us today for a quote. Our team is ready to provide expert guidance and customized solutions for your specific needs.

Our Torsion springs Manufacturing Capabilities

| Aspect | Details |

|---|---|

| Material Expertise | – Carbon Steel: 70, 72A, 72B, 82B, Imported Piano Wire, T9A, SWPB, WPC, 65Mn – General Alloy Steel: 60Si2MnA, 50CrVA, 55CrSiA, 60CrMnA, 60Cr2VA – Stainless Steel: SUS302, SUS304, SUS316, SUS631, 17-7PH – High Temperature Alloy: 30W4Cr2VA, Inconel X750, Inconel 718, Nimonic90 – Copper Alloy: Beryllium Copper, Phosphor Bronze etc. – Iron wire: Galvanized iron wire |

| End Style Variety | – Ground and Close Wound – Unground and Close Wound – Ground and Not Close Wound – Centered Circular Hook – Offset Circular Hook – Half Circular Hook etc. (Refer to Spring End Style Diagram for details) |

| Material Range Flexibility | Wire Diameter: φ0.3 – 80 mm,Sheet Thickness: δ0.1 – 25mm |

| Coil Direction Options | Left-hand/Right-hand (default: Right-hand),Active Coils,Total Coils |

| Force Requirements Meeting | Adhere to the attached Spring Drawing Style to meet various force requirements precisely. |

| Special Requirements Fulfillment | – Fatigue Life: Ensure springs meet specified fatigue life expectations. – High Temperature Resistance: Produce springs with excellent high temperature resistance capabilities. – Strong Pressure and Constant Temperature Treatment: Capable of subjecting springs to such treatments to meet the demands. – Corrosion Resistance Requirements: Manufacture springs that satisfy corrosion resistance needs. |

| Surface Treatment Options | Zinc Plating,Chrome Plating,Nickel Plating,Electrophoresis,Painting,Powder Coating,BlackeningOiling,Dacromet etc. |

| Quality Assurance | Hold ISO9001-2008 International Quality System Certification for high-quality spring processing and consistent product quality. |

| Quantity Accommodation | Prefer customers to provide quantity requirements when inquiring. Handle both small and large quantities, with a preference for larger quantities to achieve better economies of scale. |

| Transportation Adaptability | Flexible in choosing transportation methods such as Courier, Logistics, or other mutually agreed upon methods to ensure timely and safe delivery of the springs. |

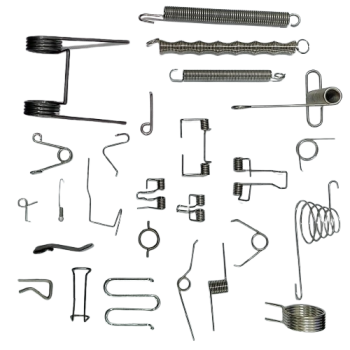

Finished Torsion springs Display

Torsion springs Manufacturing Service Experts

The types of heat sink we produce include: