Home » Springs

Springs

- Extensive Material and Finish Options

- ISO 9001 Certified Springs Manufacturer

As a leading spring manufacturer, ShixinProto focuses on providing high-quality custom spring solutions to global corporate customers. With years of industry experience and technological innovation, we provide precision springs for various industrial applications to meet the needs of customers in different fields.

Our Spring Manufacturing Services

Custom Spring Design

Our engineering team works closely with customers to provide personalized spring design solutions based on their specific requirements. From initial conception to final product delivery, we ensure that every detail meets the highest standards.

High-precision Manufacturing

Using advanced CNC equipment and precision processes, we are able to produce high-precision and high-consistency springs to ensure that each product meets stringent quality requirements.

Material Selection and Optimization

We offer a wide range of spring material options, including stainless steel, high carbon steel, alloy steel, etc., and can recommend the most suitable materials according to different usage environments and performance requirements. At the same time, we also provide material optimization suggestions to ensure the durability and elasticity of the springs.

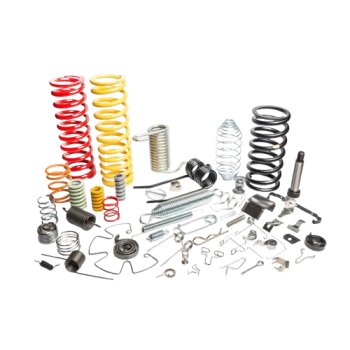

Multiple Spring Types

We are able to manufacture various types of springs, including compression springs, tension springs, torsion springs and constant force springs, etc., to meet the needs of different industries.

Quality Assurance and Testing

Our products are strictly quality controlled, and each batch of springs will undergo multiple mechanical performance tests to ensure that they meet international quality standards. Whether it is load testing, fatigue testing, or material performance testing, we strive for excellence.

Fast Delivery and Global Transportation

Our efficient production process can provide customers with fast delivery. At the same time, we have a global logistics network to ensure that the products are delivered to customers in a timely manner.

After-sales Support and Technical Consulting

We not only provide high-quality spring products, but also provide comprehensive technical consulting and after-sales support. Whether it is product optimization or new product development, our technical team can provide you with professional solutions.

Our Advantages

Rich Experience: Many years of industry experience, serving customers in multiple industries.

Professional Team: The engineering team and the production team work closely together to ensure the high precision and quality of the products.

Flexibility and Customization: Ability to provide personalized spring design and production services according to customer needs.

Global Supply Chain: Mature logistics system and global transportation network to ensure on-time delivery.

ShixinProto is committed to providing excellent spring manufacturing services to every customer. Whether you need small batch production or large-scale mass production, we can provide you with efficient and reliable solutions.

Contact us to discuss how we can help you grow your business with quality springs.

Our Springs Manufacturing Capabilities

| Aspect | Details |

|---|---|

| Material Expertise | – Carbon Steel: 70, 72A, 72B, 82B, Imported Piano Wire, T9A, SWPB, WPC, 65Mn – General Alloy Steel: 60Si2MnA, 50CrVA, 55CrSiA, 60CrMnA, 60Cr2VA – Stainless Steel: SUS302, SUS304, SUS316, SUS631, 17-7PH – High Temperature Alloy: 30W4Cr2VA, Inconel X750, Inconel 718, Nimonic90 – Copper Alloy: Beryllium Copper, Phosphor Bronze etc. – Iron wire: Galvanized iron wire |

| End Style Variety | – Ground and Close Wound – Unground and Close Wound – Ground and Not Close Wound – Centered Circular Hook – Offset Circular Hook – Half Circular Hook etc. (Refer to Spring End Style Diagram for details) |

| Material Range Flexibility | Wire Diameter: φ0.3 – 80 mm,Sheet Thickness: δ0.1 – 25mm |

| Coil Direction Options | Left-hand/Right-hand (default: Right-hand),Active Coils,Total Coils |

| Force Requirements Meeting | Adhere to the attached Spring Drawing Style to meet various force requirements precisely. |

| Special Requirements Fulfillment | – Fatigue Life: Ensure springs meet specified fatigue life expectations. – High Temperature Resistance: Produce springs with excellent high temperature resistance capabilities. – Strong Pressure and Constant Temperature Treatment: Capable of subjecting springs to such treatments to meet the demands. – Corrosion Resistance Requirements: Manufacture springs that satisfy corrosion resistance needs. |

| Surface Treatment Options | Zinc Plating,Chrome Plating,Nickel Plating,Electrophoresis,Painting,Powder Coating,BlackeningOiling,Dacromet etc. |

| Quality Assurance | Hold ISO9001-2008 International Quality System Certification for high-quality spring processing and consistent product quality. |

| Quantity Accommodation | Prefer customers to provide quantity requirements when inquiring. Handle both small and large quantities, with a preference for larger quantities to achieve better economies of scale. |

| Transportation Adaptability | Flexible in choosing transportation methods such as Courier, Logistics, or other mutually agreed upon methods to ensure timely and safe delivery of the springs. |

Finished Springs Display

Springs Manufacturing Service Experts

The types of heat sink we produce include: