Motor Shafts

- Motor Shafts Manufacturer Price, cost reduction of 30%

- Custom Motor Shafts according to drawings

- No MOQ

Our company is committed to providing high-quality motor shaft manufacturing services that can meet various industrial needs. As a key component for transmitting power and motion between electric motors and machine equipment, the accuracy and durability of motor shafts play a decisive role in the operating efficiency of the overall system. Our motor shaft designs are widely used in many fields such as automotive, aviation, electronics, manufacturing and mechanical engineering.

Motor Shaft Product Features

Diverse Shaft Types

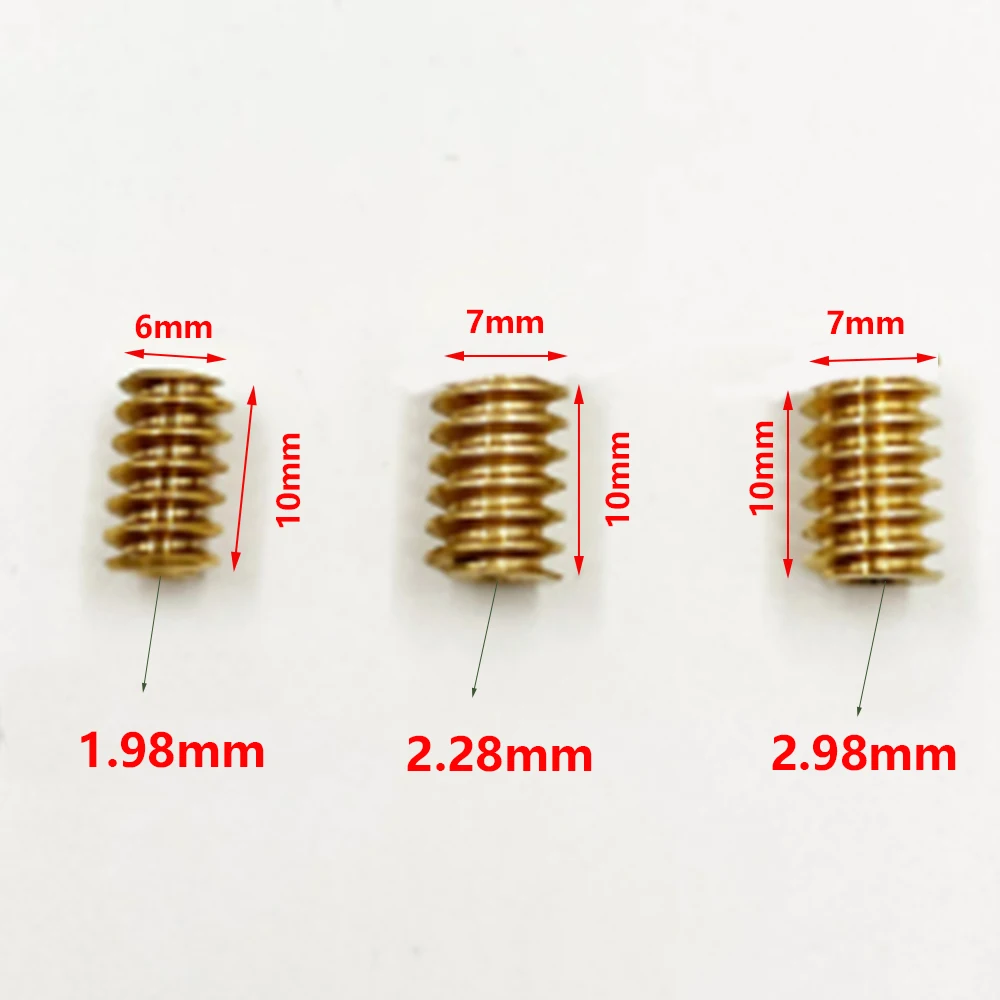

We are able to manufacture various types of motor shafts, including round, square, stepped, splined shafts, spiral shafts, etc. to meet the special needs of different equipment and systems. Customers can choose the appropriate shaft design according to the specific application scenario to ensure the best working performance.

Customized Design and Manufacturing

We provide customized design services to ensure that the motor shaft fully meets the customer’s technical requirements. Whether it is special dimensions, complex geometries, or strict tolerance requirements, our design team can accurately evaluate the requirements and develop the most suitable production plan. Through design simulation and simulation with advanced CAD software, we ensure that every detail can achieve the best mechanical performance.

High-precision Production

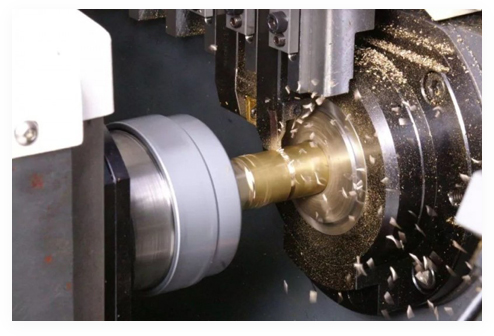

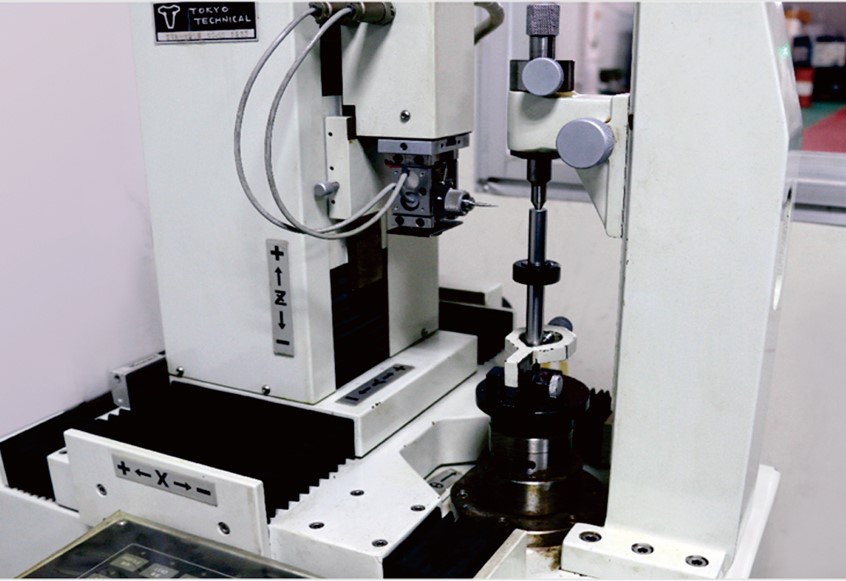

Our motor shafts are produced using modern CNC machining equipment to ensure that the accuracy of each shaft meets the highest standards. High-precision manufacturing processes such as centerless grinding, CNC turning, and milling enable us to produce products with high surface finish and precise dimensions, reducing customers’ subsequent adjustment and maintenance costs.

Selection of high-quality materials

We use a variety of high-strength materials to manufacture motor shafts, including medium carbon steel (such as SAE 1045), alloy steel, stainless steel, etc. These materials have excellent mechanical properties and can withstand large loads and high-frequency operation. For specific industrial needs, we can also provide special material options with strong corrosion resistance, high temperature resistance or wear resistance to ensure that the motor shaft can still operate stably for a long time under extreme working conditions.

Strict quality control

Our company’s quality management system fully complies with the requirements of ISO 9001:2015 certification. Every production link is strictly inspected and tested to ensure that the product meets customer requirements in terms of geometric dimensions, concentricity, hardness, etc. We use advanced testing equipment, including three-coordinate measuring machines and optical inspection systems, to ensure that every detail of the product meets international standards.

Heat treatment process

According to customer requirements, we can provide a variety of heat treatment processes for motor shafts, such as quenching, tempering and surface hardening. These processes can significantly improve the strength and hardness of the motor shaft, increase its fatigue resistance and service life, especially in high-strength application scenarios.

Production Capacity and Delivery Speed

Our production lines are equipped with modern automated equipment, which can efficiently produce large quantities of motor shafts to meet the needs of various customers. With optimized production processes and flexible supply chain management, we are able to complete large-scale production orders in a short period of time and ensure on-time delivery. In addition, we provide global transportation services to ensure that customers can receive products on time no matter where they are.

Customer Service and Technical Support

We have an experienced team of engineers who can provide comprehensive technical support to our customers. From product design, material selection to process optimization, we provide customers with advice and solutions throughout the process to ensure that each project goes smoothly. Whether it is the development of new products or the improvement of existing products, we can provide professional consulting and customized services to help customers improve product performance and competitiveness.

Motor Shaft Application Areas

Our motor shafts are widely used in multiple industries, covering automotive, aviation, medical equipment, home appliances, industrial automation and heavy machinery. Especially in the fields with high performance requirements, such as electric vehicle drive systems, wind turbines and precision industrial robots, our motor shafts have been widely recognized by customers for their high precision and reliability.

As an industry-leading motor shaft manufacturer, we are always committed to providing customers with the best quality products and services. With advanced manufacturing technology, rich experience and global supply chain management, we are able to create value for customers in a highly competitive market. Whether it is standard products or customized designs, we can meet the various needs of customers and ensure the success of every project.

We look forward to working with you to provide high-performance and long-life motor shaft products for your project. If you have any needs or questions, please feel free to contact us, we will wholeheartedly provide you with the best solution.

- Jump to Section

- Workshop

- Material

- Advantages

- Faq

- Finished product

- Applications

Motor Shafts Manufacturer Workshop

Motor Shafts Material Selection

- Carbon Steel

- Alloy Steel

- Stainless Steel

- Tool Steel

- Nickel Alloys

- Beryllium Copper

- Composite Materials

- Titanium Alloy

- Bronze & Brass

- Cast Iron

- Aluminum Alloys

- Engineering Plastics

Why Choose Us

Frequently ask question

We manufacture a variety of shafts, including Custom Shafts, Forged Shafts, Gear Shafts, Motor Shafts, Spline Shafts, and Worm Shafts, tailored to fit specific industry applications.

Yes, we offer fully customizable shafts based on your technical requirements, ensuring a perfect fit for your application.

Our pricing is highly competitive, with savings of up to 30% compared to other manufacturers, without compromising on quality.

We pride ourselves on fast turnaround times, typically delivering products within 7 days to keep your projects moving efficiently.

We implement strict quality control throughout the manufacturing process, from material selection to final testing, ensuring every shaft meets high international standards.

Yes, we welcome clients to visit our factory to see our production process and quality control measures firsthand.

Yes, we provide worldwide delivery, ensuring that our products reach you wherever you are, on time and in perfect condition.

Our shafts are used across multiple industries, including automotive, heavy machinery, aerospace, energy, and many more.

Our technical team is available to help guide you in selecting the right shaft type, materials, and specifications for your specific needs.

Yes, we offer flexibility in production, allowing for both large and small batch orders to suit the varying needs of our customers, with fast delivery times.

Finished Motor Shafts Display

Applications

- Automotive

- Construction

- Electrical

- Electronics

- Heavy Equipment

- Industrial Machinery

- Marine

- Medical Devices

- Off-Highway

- Pneumatics

Services

-

Casting

-

Climb Hobbing

-

Conventional Hobbing

-

Forging

-

Grinding

-

Heat Treating

-

Honing

-

Flame Cutting

-

Lapping

-

Milling

-

Shaping

-

Shaving

Motor Shafts Manufacturing Service Experts

The types of shafts we produce include: