Forged Shafts

- Forged Shafts Manufacturer Price, cost reduction of 30%

- Custom Forged Shafts according to drawings

- No MOQ

Utilizing advanced forging techniques, we offer cost-effective solutions compared to precision-machined shafts from bar stock. With our extensive expertise, we are capable of producing a wide variety of forged shaft styles from a broad selection of materials. We accommodate production lot sizes from hundreds to hundreds of thousands, ensuring flexibility and scalability to meet diverse industry demands.

Why choose us as your forged shaft supplier?

Cost-effectiveness: Compared with shafts precision-machined from bar stock, our forged shaft production process has significant cost advantages. By optimizing material utilization and reducing processing time, we help customers effectively save procurement costs.

Wide range of sizes: We can produce according to your size requirements to meet the needs of different application scenarios. Whether you need small precision parts or large industrial components, we can provide solutions.

Flexible batch production: We support production batches ranging from hundreds to hundreds of thousands, and can flexibly adjust the production scale according to customer needs. Whether it is small batch customization or large-scale mass production, we can respond quickly.

Multiple material options: We have the ability to handle a variety of material types, from carbon steel, stainless steel to alloy steel and special materials, and we can customize production according to your application requirements and specified materials.

Quality product guarantee: Our forged shaft products meet strict quality standards, ensuring that each shaft has excellent strength, durability and precision for demanding industrial environments.

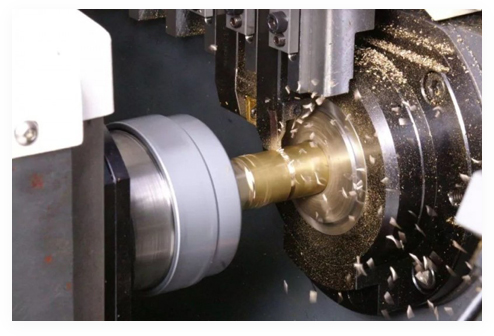

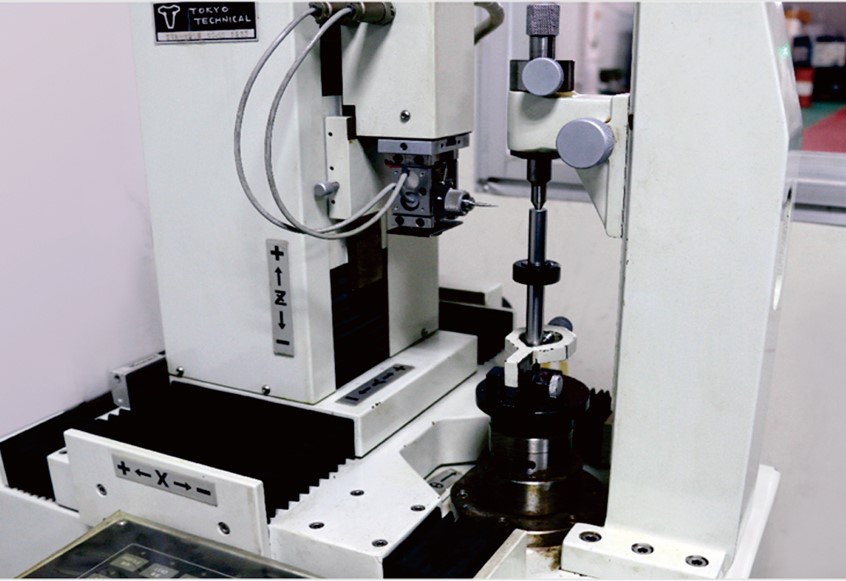

Professional team and advanced equipment: We have an experienced engineering team and advanced production equipment to ensure that every link from design to manufacturing meets the highest standards and provide customers with reliable product and service support.

Choose us, you will get competitive prices, high-quality products and flexible services. We are committed to becoming your trusted long-term partner.

- Jump to Section

- Workshop

- Material

- Advantages

- Faq

- Finished product

- Applications

Forged Shafts Manufacturer Workshop

Forged Shafts Material Selection

- Carbon Steel

- Alloy Steel

- Stainless Steel

- Tool Steel

- Nickel Alloys

- Beryllium Copper

- Composite Materials

- Titanium Alloy

- Bronze & Brass

- Cast Iron

- Aluminum Alloys

- Engineering Plastics

Why Choose Us

Frequently ask question

We manufacture a variety of shafts, including Custom Shafts, Forged Shafts, Gear Shafts, Motor Shafts, Spline Shafts, and Worm Shafts, tailored to fit specific industry applications.

Yes, we offer fully customizable shafts based on your technical requirements, ensuring a perfect fit for your application.

Our pricing is highly competitive, with savings of up to 30% compared to other manufacturers, without compromising on quality.

We pride ourselves on fast turnaround times, typically delivering products within 7 days to keep your projects moving efficiently.

We implement strict quality control throughout the manufacturing process, from material selection to final testing, ensuring every shaft meets high international standards.

Yes, we welcome clients to visit our factory to see our production process and quality control measures firsthand.

Yes, we provide worldwide delivery, ensuring that our products reach you wherever you are, on time and in perfect condition.

Our shafts are used across multiple industries, including automotive, heavy machinery, aerospace, energy, and many more.

Our technical team is available to help guide you in selecting the right shaft type, materials, and specifications for your specific needs.

Yes, we offer flexibility in production, allowing for both large and small batch orders to suit the varying needs of our customers, with fast delivery times.

Finished Forged Shafts Display

Applications

- Automotive

- Construction

- Electrical

- Electronics

- Heavy Equipment

- Industrial Machinery

- Marine

- Medical Devices

- Off-Highway

- Pneumatics

Services

-

Casting

-

Climb Hobbing

-

Conventional Hobbing

-

Forging

-

Grinding

-

Heat Treating

-

Honing

-

Flame Cutting

-

Lapping

-

Milling

-

Shaping

-

Shaving

Forged Shafts Manufacturing Service Experts

The types of shafts we produce include: