Home » Shafts

Shafts

Manufactures a wide variety of shafts for automotive manufacturers, industrial machinery and other applications.

- Competitively priced Save 30%

- Fast turnaround in 7 days

- Real factory welcome to visit

- Worldwide delivery

Our Products

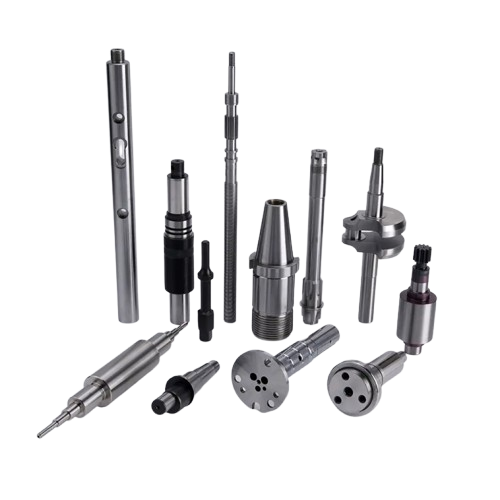

High Quality Shaft Products

When you need shafts products, we are here

We excel in providing custom shaft solutions to meet specific industry needs. Whether you need precision shafts for automotive, aerospace or industrial applications, we can design and manufacture them to exacting specifications to meet stringent performance standards.

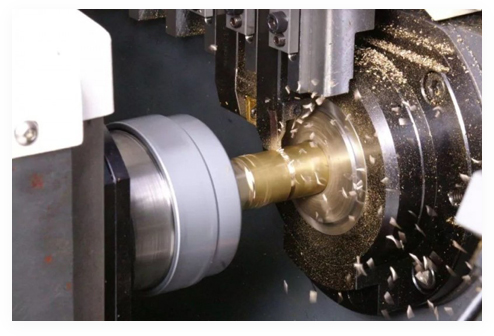

Utilizing state-of-the-art manufacturing techniques, we ensure the production of high-quality, durable shafts. Our factories are equipped with the latest CNC machining and turning centers, allowing for high-precision, efficient mass production.

We provide more than just manufacturing. Our team provides comprehensive engineering support from the initial design phase to after-sales service, ensuring that each product not only meets but exceeds your expectations in terms of performance and reliability.

Our Shafts Manufacturing Facility

Our shaft manufacturing plant is equipped with cutting-edge machinery and staffed with experienced experts dedicated to providing high-quality shafts.

Frequently ask question

We produce a wide variety of shafts including drive shafts, precision shafts, spline shafts and custom shafts to meet specific industry needs.

Our shafts are made from a variety of high-grade materials, including stainless steel, carbon steel, aluminum and specialty alloys to ensure durability and performance.

Absolutely! We specialize in customizing shafts according to specific customer requirements and specifications.

Quality is our top priority. We utilize advanced manufacturing processes and rigorous testing procedures, including dimensional inspections and material testing, to ensure each shaft meets our high standards.

Lead times vary based on complexity and order size, but we strive to deliver as efficiently as possible and can provide expedited services when needed.

Our facility is equipped to handle both high-volume production runs and smaller, bespoke orders with equal efficiency.

Finished Shafts Display

Shafts Buying Guide

The choice of shafts has a significant impact on production efficiency, cost, and maintenance needs in addition to directly affecting the equipment’s life and performance. In order to assist clients in selecting shafts that meet their needs, I have put up the selection guide that follows.

1. Make the application environment clear.

Selecting an appropriate shaft requires first understanding the working requirements and use environment of the shaft. You need to take the following things into account:

Type and size of load: The shaft is capable of supporting combination, radial, and axial loads. High-strength materials are needed for shafts operating in situations with shock or vibration, heavy loads, or fast speeds.

Working speed: Shaft material, balance, and surface quality must meet strict standards for high-speed rotating machinery.

Temperature: While cold-resistant materials may be necessary in low-temperature settings, shafts operating in high-temperature environments must possess strong heat and oxidation resistance.

Corrosive environment: Materials that are resistant to corrosion or surface treatments for the shaft, like galvanizing or nickel plating, are required for humid, acidic, alkaline, and other corrosive conditions.

2. Select the appropriate content

The shaft’s dependability and service life are directly impacted by the material selection. Typical materials for shafts are:

Carbon steel is a material that is frequently used in mechanical equipment because it is strong and resistant to wear.

Alloy steel: stronger and more fatigue resistant, ideal for high-load, high-speed applications.

Stainless steel is expensive but very resistant to rust, making it ideal for harsh settings.

Composite materials: Lighter composite materials can be used in some specific applications to save weight and increase fatigue resistance.

3. Take manufacturing precision into account

There are differences in the machining precision requirements for different shafts. The rotational stability and service life of high-precision shafts are often better. Clients should consider the following while selecting the accuracy level:

Tolerance: choose a tolerance range that satisfies the equipment’s specifications to guarantee a tight fit with other equipment components.

Surface roughness: reduced friction and wear result from a smoother surface, making it ideal for high-speed rotating machinery.

4. Reasonable layout

The shaft’s structural design must be modified to account for various applications:

Solid shafts have more torsional strength than hollow shafts, which are typically utilized in equipment that needs to be lightweight while maintaining strength.

Reasonable diameter and length design: In order to minimize processing costs and material waste, the diameter and length of the shaft should be kept as close to the required values as feasible while still meeting the requirements for strength and rigidity.

5. Lubrication and surface treatment

Surface treatment and lubrication are essential procedures to increase the shaft’s service life:

Surface treatment: By plating, nitriding, quenching, and other methods, the shaft’s surface hardness and wear resistance can be increased, making it appropriate for usage in high-friction and easy-wear working situations.

Lubrication: To lessen shaft friction and increase shaft life, select an appropriate lubrication technique, such as oil, grease, or solid lubrication.

6. Be mindful while choosing a provider and brand

Selecting a dependable supplier is crucial for guaranteeing shaft quality and servicing. Our factory possesses extensive expertise in shaft processing and can offer you superior products along with comprehensive service assistance.

Professionalism and technical prowess: Our factory has produced high-precision shafts for many years, and our technical staff is knowledgeable with the various shafts’ processing technologies. As a result, we can offer our customers a one-stop shop for solutions ranging from design to production. We can satisfy your needs whether they include a simple custom shaft or a sophisticated conventional shaft.

Strict quality control system: All goods are rigorously tested and examined to guarantee that each shaft satisfies the highest industry requirements. Our factory has obtained ISO quality certification. Shaft stability and accuracy are guaranteed by state-of-the-art machinery and flawless production flow.

Tailored service: Our factory can produce shafts to customers’ particular specifications in addition to offering conventional specs. We can react quickly and make sure that the product’s performance satisfies the needs of the customer’s equipment, regardless of the particular materials, surface treatment, or size specifications.

Delivery that is quick and effective as well as after-sales support: Our plant has a robust production capacity and an effective supply chain to guarantee that customers may receive their orders on time and prevent production losses from delays. In addition, we offer a comprehensive after-sales support system to promptly address any issues that clients may encounter while using our products.

7. Price and value for money

While cost is a significant factor in shaft purchases, buyers should examine the entire life cycle cost of the product. High-quality shafts may cost more up front, but they will save money over time in terms of replacement prices, service life, and frequency of maintenance.

When buying shafts, you should think about the application environment, materials, manufacturing precision, design requirements, and the brand and supplier’s reputation in addition to pricing. An appropriate shaft choice can prolong the equipment’s useful life, increase operational efficiency, and lower total operating costs.

With this guide, I wish to empower customers to make better judgments. Please don’t hesitate to contact me with any queries you may have regarding shaft selection, and I will be happy to offer you more thorough expert guidance.

Request for a service today

Sed turpis tincidunt id aliquet risus feugiat in. Felis bibendum ut tristique et.