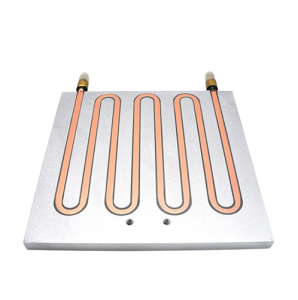

Liquid Cooled Heat Sink

- Tolerances as tight as ±0.0005 mm ensure exceptional accuracy.

- Tailored Liquid Cooled Heat Sink and recalibration services meet unique measurement needs.

As technology advances, heat management becomes increasingly critical for high-power applications. At Shixinproto, we provide custom liquid-cooled heat sinks designed to handle extreme thermal loads efficiently. Whether you’re managing heat in electric vehicles, data centres, or industrial machinery, our liquid-cooled solutions deliver unparalleled thermal performance and reliability.

What Is a Liquid Cooled Heat Sink?

Unlike traditional air-cooled systems, liquid-cooled heat sinks use a liquid (typically water or a coolant mixture) to transfer heat away from components. This approach ensures:

- Superior Heat Dissipation: Ideal for high-power or densely packed systems.

- Compact Designs: Enables smaller heat sinks without compromising performance.

- Quiet Operation: Reduced reliance on fans, lowering noise levels.

Applications of Liquid Cooled Heat Sinks

Our liquid-cooled heat sinks are tailored for a variety of demanding applications, including:

- Electric Vehicles (EVs): Efficient cooling for batteries, motors, and inverters.

- Data Centres: Managing heat in high-performance servers and computing systems.

- Industrial Equipment: Thermal control for heavy machinery and robotics.

- Medical Devices: Reliable cooling for imaging and diagnostic systems.

- Power Electronics: Heat dissipation for IGBTs, MOSFETs, and other power modules.

Our Liquid-Cooled Heat Sink Capabilities

1. Custom Design Options

We work closely with you to develop a solution that perfectly meets your project’s needs, offering:

- Flow Channels: Precision-engineered channels for optimal fluid flow and heat transfer.

- Integration: Support for mounting components, connectors, or sensors.

- Scalability: Prototypes, small batches, or large-scale production.

2. Materials

Our heat sinks are crafted from premium materials to ensure durability and efficiency:

- Aluminium Alloys: Lightweight and cost-effective.

- Copper: Superior thermal conductivity for extreme cooling demands.

- Composite Materials: For specialised applications requiring advanced properties.

3. Manufacturing Processes

- CNC Machining: Precision shaping of intricate fluid channels.

- Brazing & Welding: Leak-proof joining of components.

- Anodising: Corrosion resistance for long-term durability.

Why Choose Shixinproto for Liquid Cooled Heat Sinks?

Expert Engineering

Our team of experienced engineers designs and manufactures efficient, leak-proof heat sinks tailored to your specifications.

Advanced Technology

Equipped with state-of-the-art CNC machinery and brazing equipment, we deliver solutions with exceptional quality and reliability.

Rigorous Quality Control

Each heat sink undergoes stringent testing, including pressure tests and flow rate evaluations, to ensure optimal performance and durability.

Customised Solutions

From size and shape to surface treatments and materials, we offer fully customisable liquid-cooled heat sinks for your unique application.

Industries We Serve

- Automotive and EV: High-efficiency cooling for batteries and power electronics.

- Aerospace: Lightweight and high-performance solutions for avionics and propulsion systems.

- Renewable Energy: Managing heat in solar inverters and wind turbine electronics.

- Electronics: Reliable thermal solutions for high-power circuits.

Partner with Shixinproto for Liquid Cooled Heat Sink Solutions

With over 14 years of experience, ISO 9001:2015 certification, and cutting-edge manufacturing capabilities, Shixinproto is your trusted partner for high-performance thermal management. Our liquid-cooled heat sinks are engineered for maximum efficiency, ensuring your products stay cool under pressure.

👉 Get a Custom Quote Today

Contact us now to discuss your project and discover the Shixinproto difference in thermal management!

Our Liquid Cooled Heat Sink Manufacturing Capabilities

Our heat sinks offer 200 specifications, customizable options, a variety of materials, precise machining accuracy, and outstanding thermal conductivity.

| Item | Parameter |

|---|---|

| Specification Support | 200 specifications and customization |

| Size Range | 30-600 mm |

| Manufacturing Accuracy | ±0.01 mm |

| Surface Finish | Ra ≤ 0.1 μm |

| Material Options | – Aluminum Alloy: Excellent thermal conductivity and light weight, widely used in most electronic devices |

| – Copper: Better thermal conductivity, suitable for high-power, high-heat load devices, efficiently conducts heat | |

| – Aluminum-Magnesium Alloy: Excellent strength and light weight, suitable for high-strength applications | |

| – Other Materials: Stainless steel, graphite, titanium alloy, plastic composite materials, and ceramics, customizable based on customer needs |

Finished Liquid Cooled Heat Sink Display

Liquid Cooled Heat Sink Manufacturing Service Experts

The types of heat sink we produce include: