Copper Heat Sink

- Tolerances as tight as ±0.0005 mm ensure exceptional accuracy.

- Tailored Copper Heat Sink and recalibration services meet unique measurement needs.

When precision and performance meet, Shixinproto Copper Heat Sinks deliver unmatched thermal management solutions for modern electronics. With industry-leading skived fin technology, a dedication to customization, and materials of superior thermal conductivity, Shixinproto is your trusted partner for high-performance copper heat sinks.

Why Choose Copper Heat Sinks?

Copper is a game-changer in thermal management:

- Exceptional Thermal Conductivity: With a thermal conductivity of ~398 W/m·K, copper far outperforms other materials like aluminum.

- Durability: Copper’s density ensures longer-lasting and more reliable heat sink performance.

- Compact Efficiency: Ideal for high-demand applications where space is limited but heat dissipation requirements are high.

Shixinproto’s Key Features

Advanced manufacturing processes ensure precise and efficient solutions. Skived fin technology creates high-aspect-ratio fins for maximum heat dissipation, while cold forging produces durable and accurate heat sinks perfect for compact and high-performance devices. We offer pure copper heat sinks for maximum thermal efficiency as well as hybrid designs combining copper cores with aluminum fins to balance cost, weight, and conductivity.

Customization is at the heart of our services. Every application is unique, and we work closely with you to create tailored solutions with custom dimensions and application-specific designs, including options for CPU cooling, LED lighting, automotive electronics, and telecom base stations. With our rapid prototyping service, we ensure seamless project timelines by delivering prototypes within two weeks.

Application Scenarios

In data centers, Shixinproto copper heat sinks efficiently cool high-performance CPUs and GPUs, reducing operational temperatures, enhancing performance, and lowering energy costs. For LED lighting, our designs manage heat effectively to extend lifespan and ensure consistent performance. Automotive electronics benefit from our heat sinks in hybrid and electric vehicles, managing the heat generated by inverters and other high-power components. Our compact and high-performance heat sinks are essential in 5G telecom equipment, providing reliable thermal management in space-constrained, high-demand environments.

How Shixinproto Outperforms Competitors

| Feature | Shixinproto | Competitors |

|---|---|---|

| Material Options | Pure Copper, Copper-Aluminum Hybrids | Mostly standard designs |

| Manufacturing Techniques | Skived Fin, Cold Forging | Limited to basic extrusions |

| Customization | Full-service design, prototyping | Minimal customization |

| Application Expertise | Automotive, Telecom, Electronics | General-purpose focus |

| Support | 24/7 technical and design assistance | Standard office hours |

Frequently Asked Questions

Why use copper instead of aluminum for heat sinks?

Copper offers superior thermal conductivity and durability, making it ideal for high-performance applications. While it is heavier and costlier, its benefits outweigh these drawbacks in critical scenarios.

Can Shixinproto customize heat sinks for unique applications?

Absolutely! We specialize in custom heat sink designs to match your exact specifications, whether it’s size, shape, or material composition.

Do you support global delivery?

Yes, we provide global shipping and support, ensuring timely delivery no matter your location.

Contact Us Today!

Ready to elevate your thermal management? Get in touch with Shixinproto for expert guidance, tailored designs, and industry-leading performance.

Our Copper Heat Sink Manufacturing Capabilities

Our heat sinks offer 200 specifications, customizable options, a variety of materials, precise machining accuracy, and outstanding thermal conductivity.

| Item | Parameter |

|---|---|

| Specification Support | 200 specifications and customization |

| Size Range | 30-600 mm |

| Manufacturing Accuracy | ±0.01 mm |

| Surface Finish | Ra ≤ 0.1 μm |

| Material Options | – Aluminum Alloy: Excellent thermal conductivity and light weight, widely used in most electronic devices |

| – Copper: Better thermal conductivity, suitable for high-power, high-heat load devices, efficiently conducts heat | |

| – Aluminum-Magnesium Alloy: Excellent strength and light weight, suitable for high-strength applications | |

| – Other Materials: Stainless steel, graphite, titanium alloy, plastic composite materials, and ceramics, customizable based on customer needs |

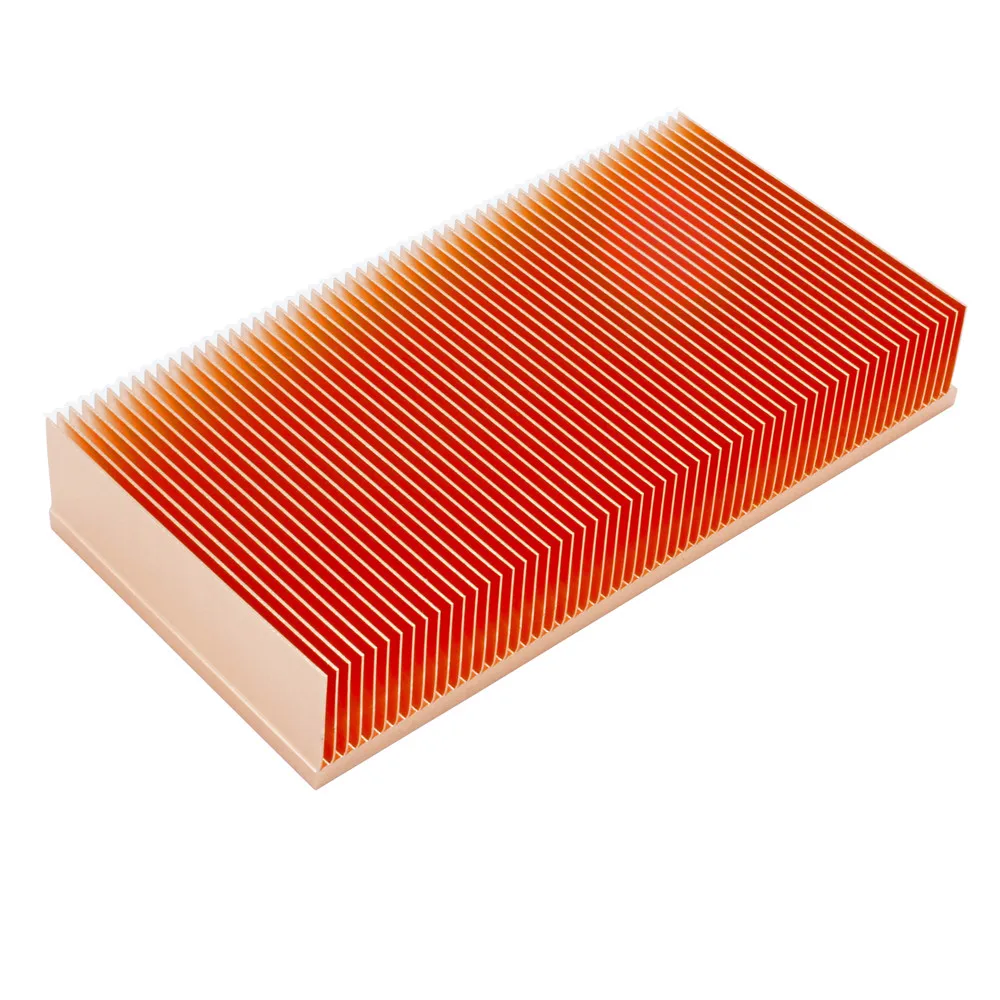

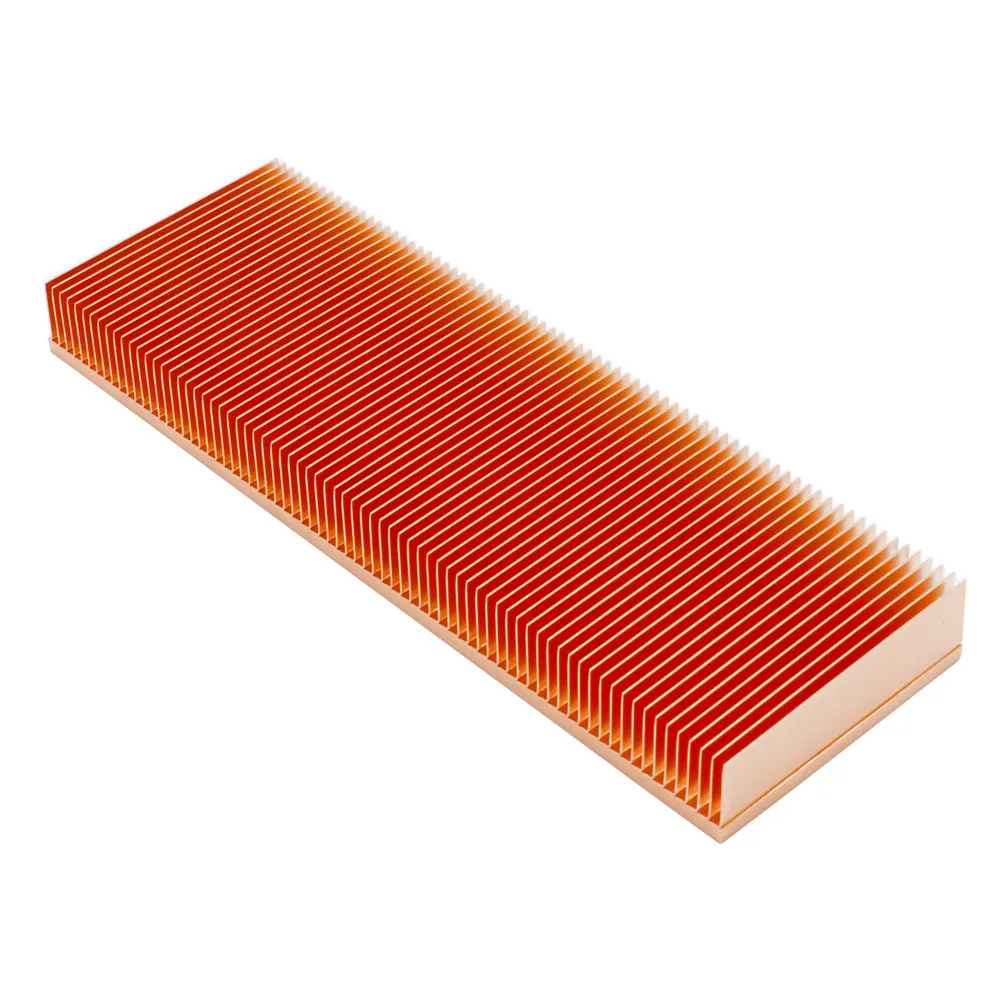

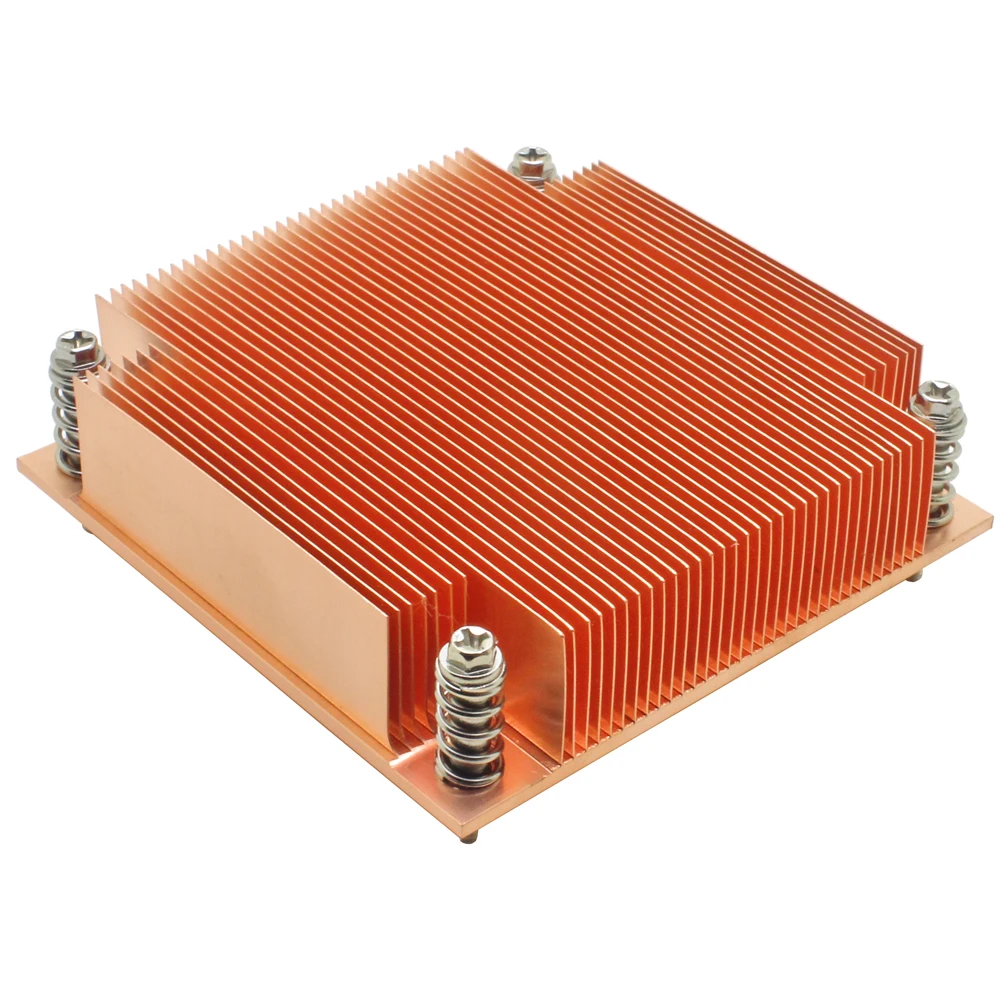

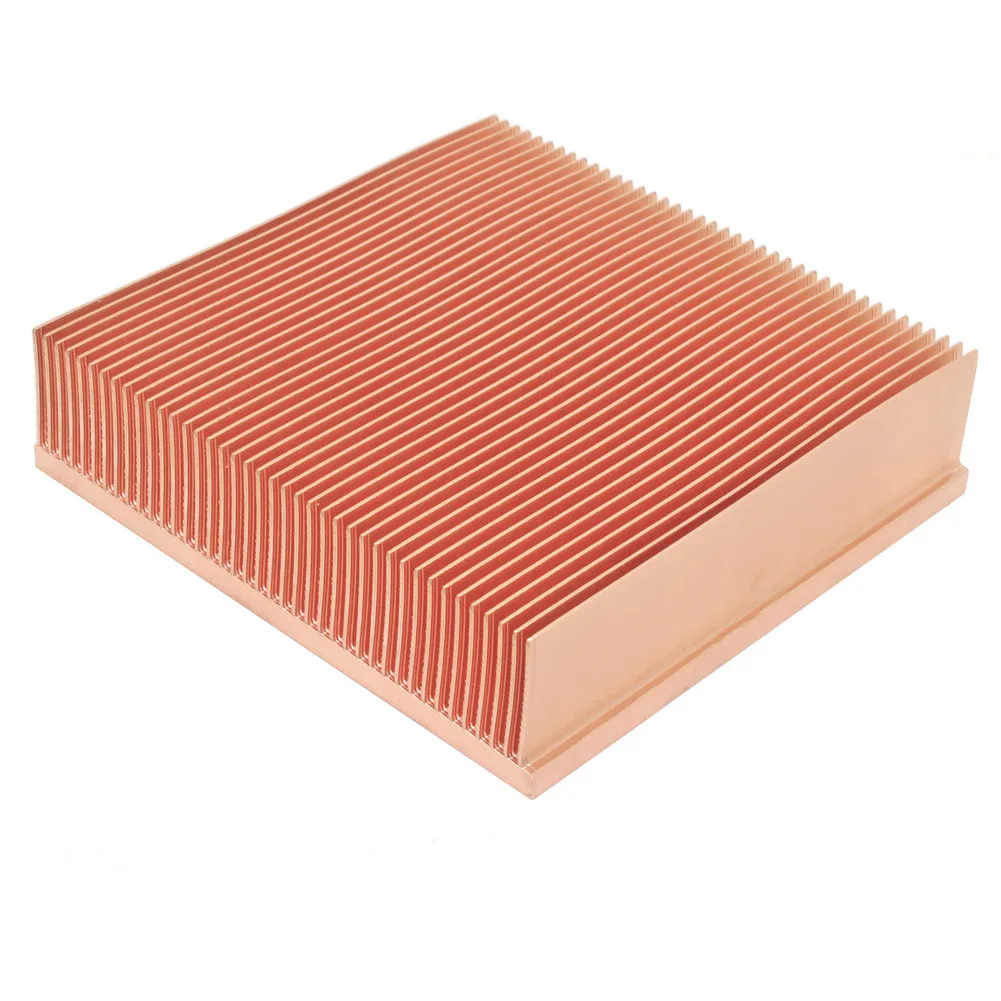

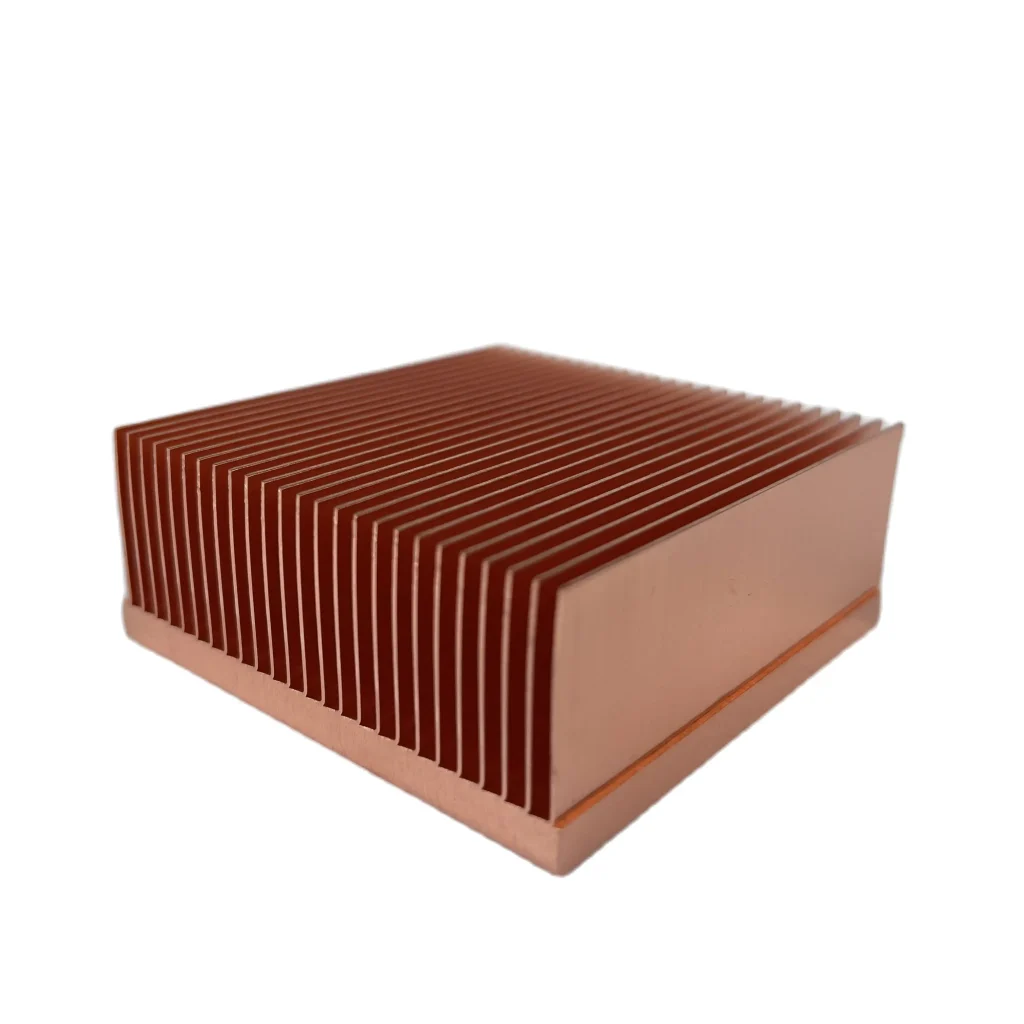

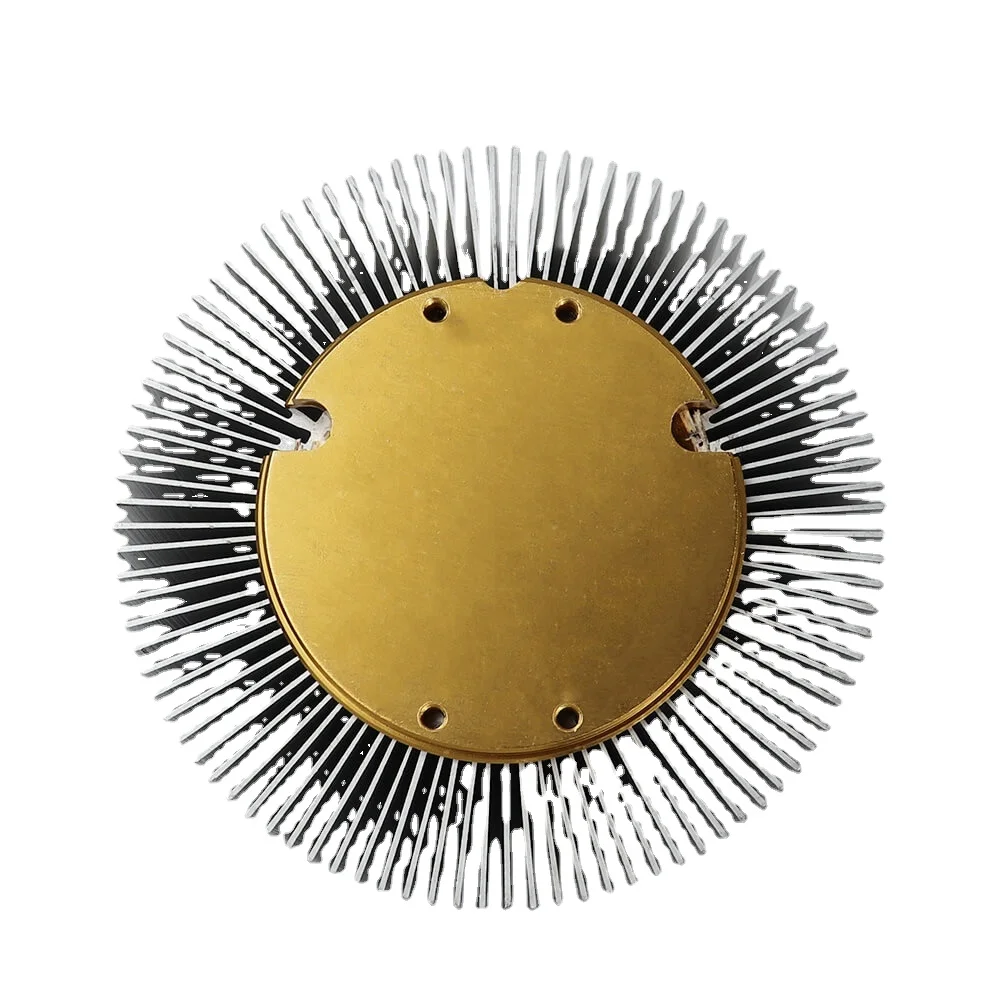

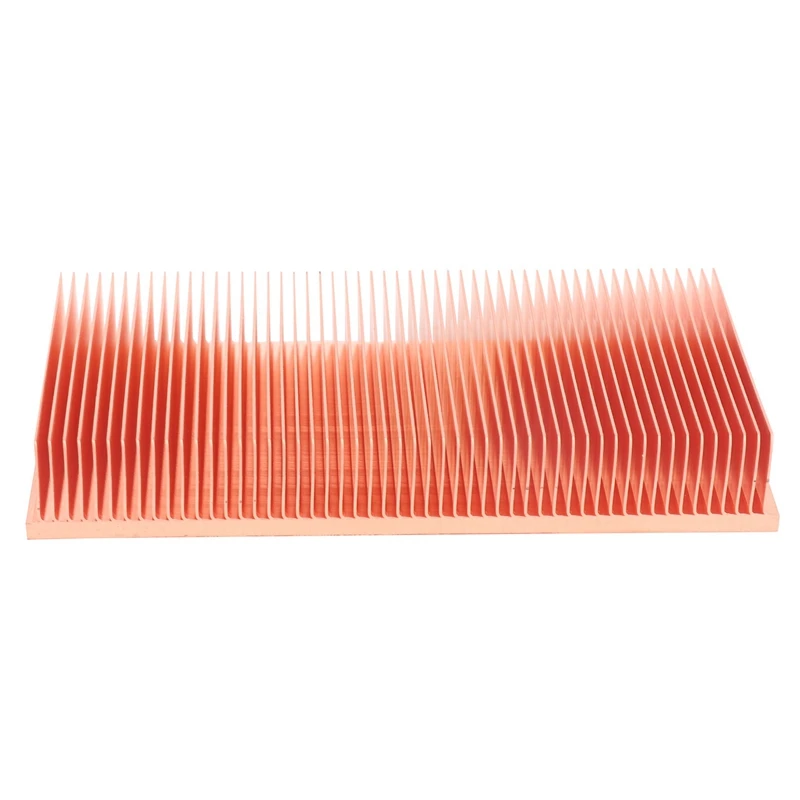

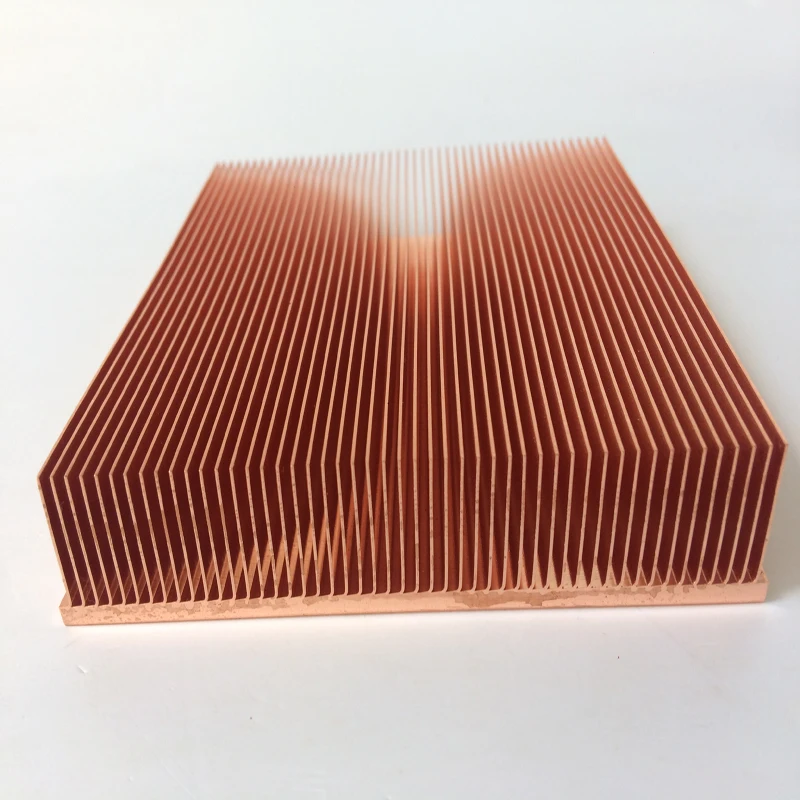

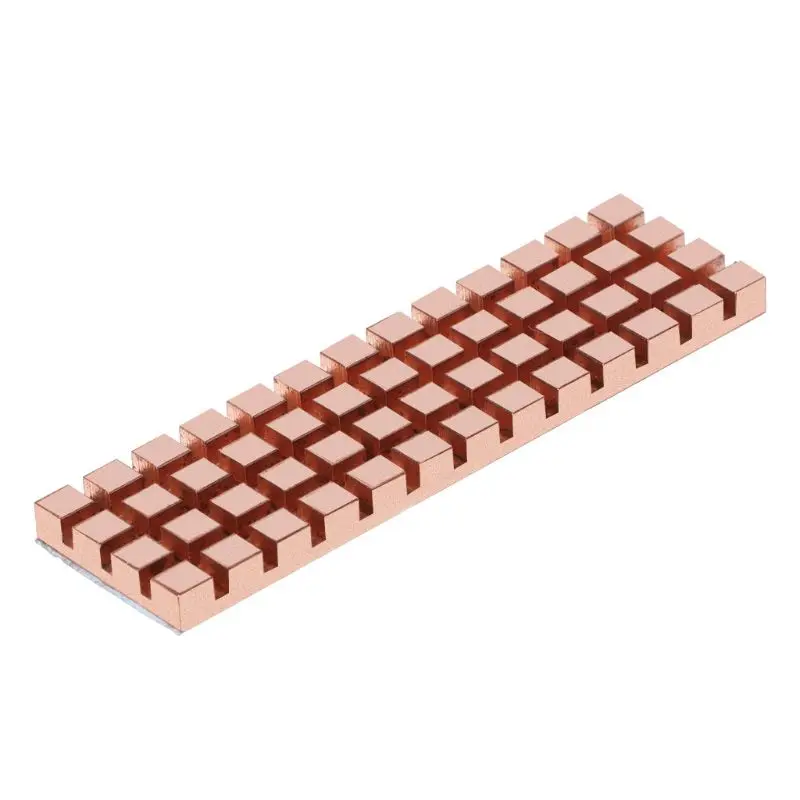

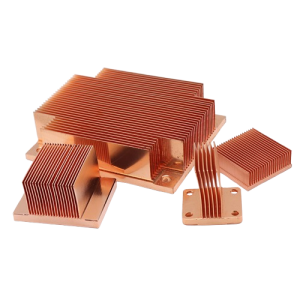

Finished Copper Heat Sink Display

Copper Heat Sink Manufacturing Service Experts

The types of heat sink we produce include: