- EN 10204-3.2 Certified

- ISO 2768 F/M Standard

- ISO 9001 Certifi

Home » Heat Sink

Heat Sink

A professional heat sink manufacturer, dedicated to providing efficient and reliable heat dissipation solutions for all walks of life.

- Made of copper or high-strength aluminum alloy, durable and long life.

- Supports 200 specifications and customization, with a size range of 30-600 mm.

- Manufacturing accuracy ±0.01 mm, surface finish Ra ≤ 0.1 μm.

Our Products

Heat Sink Types

All products have passed ISO9001 & 14001 certification

Manufacturer

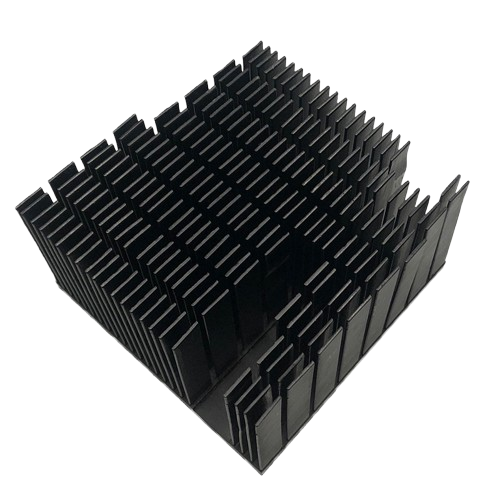

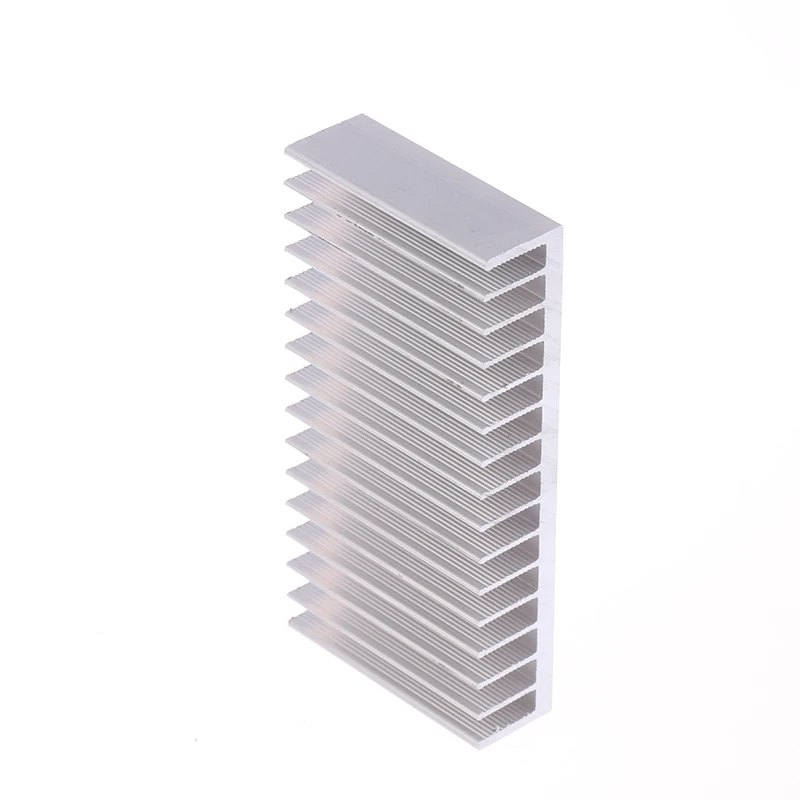

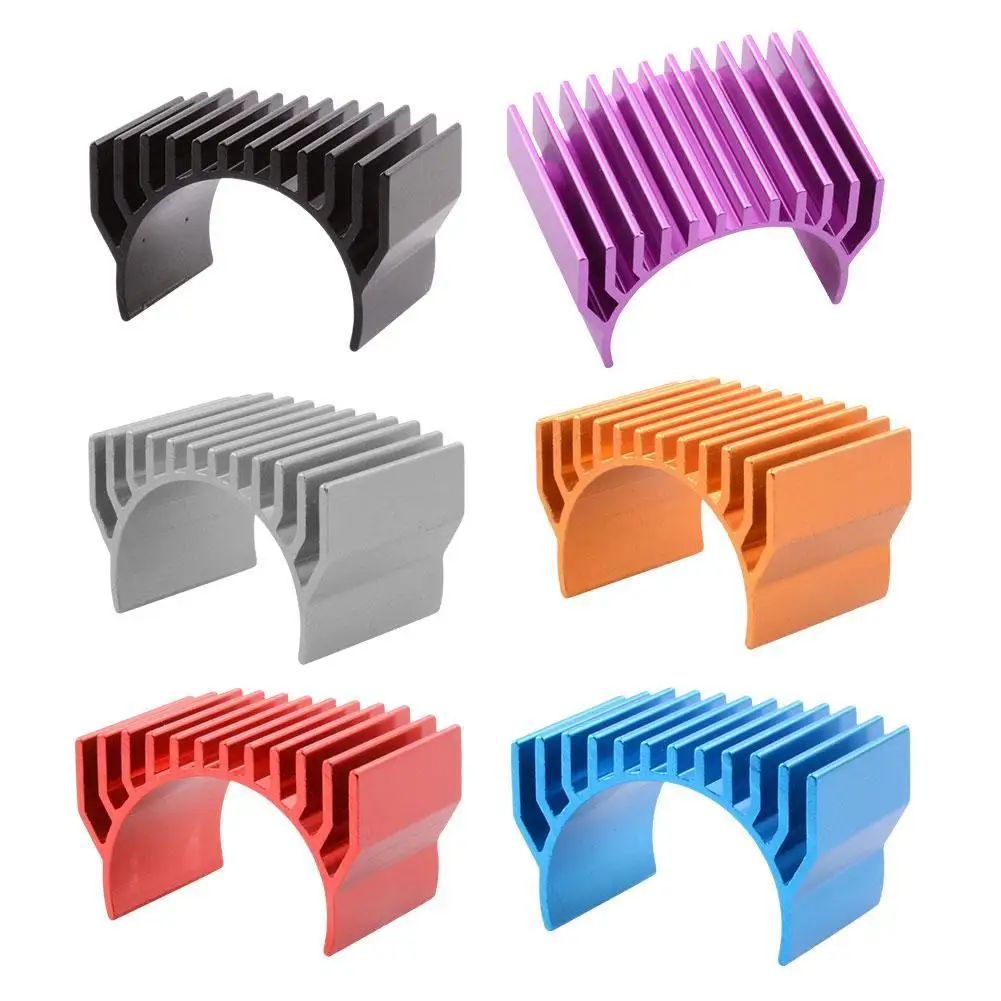

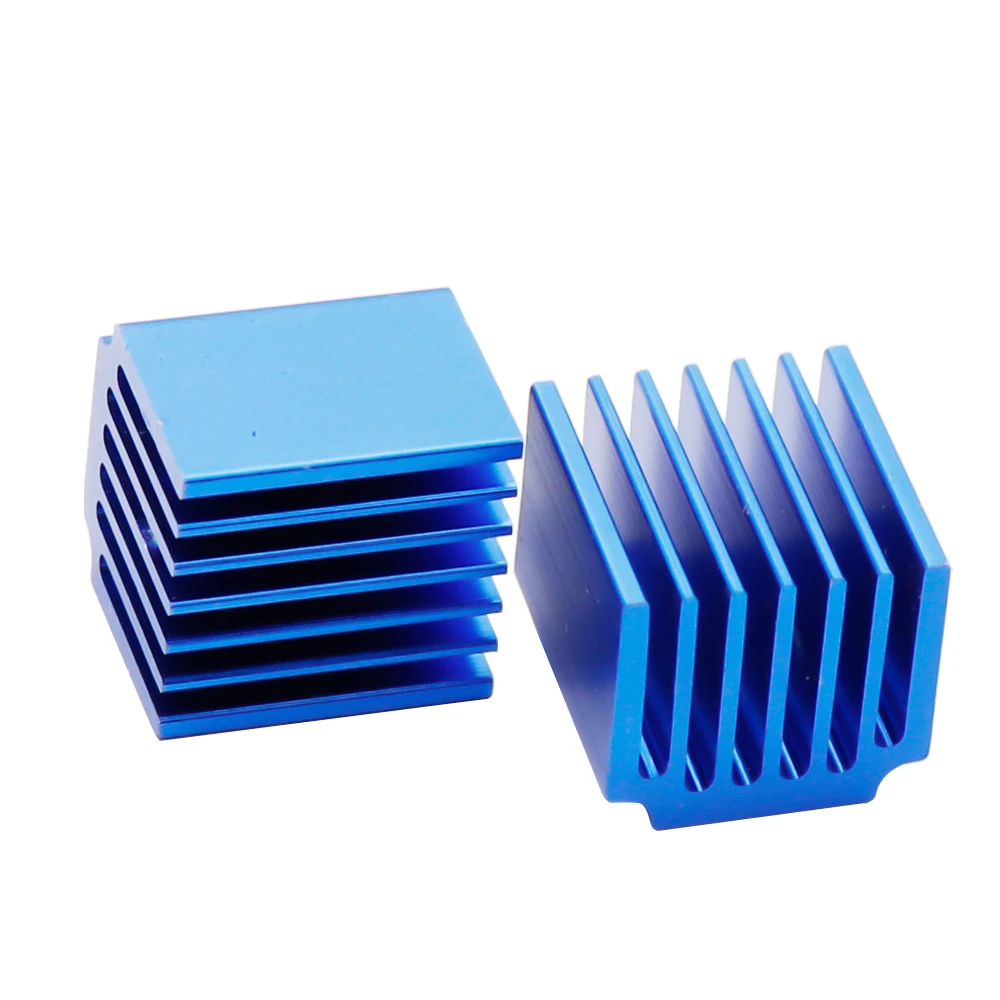

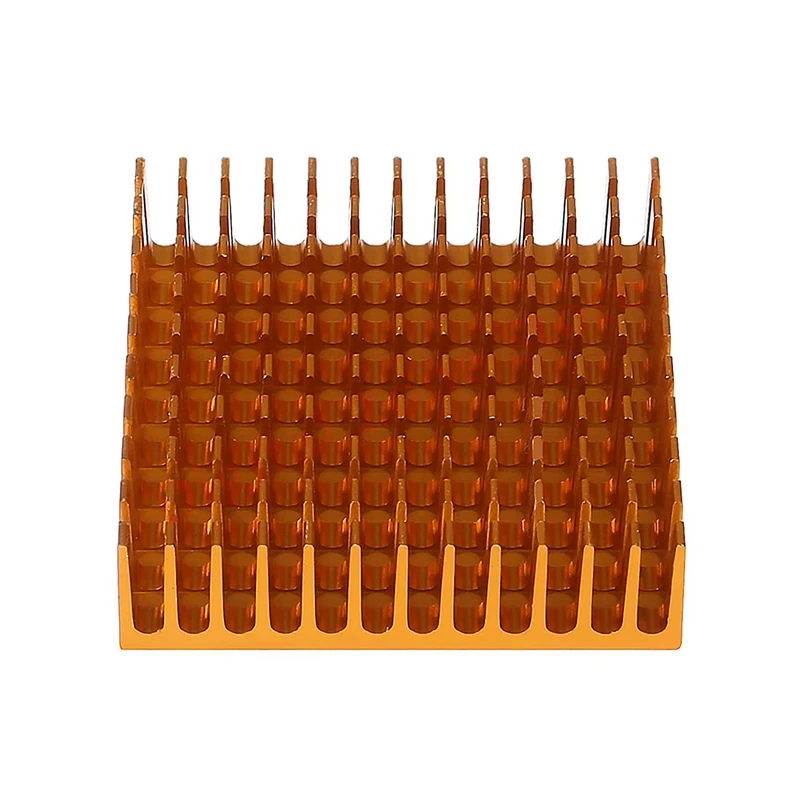

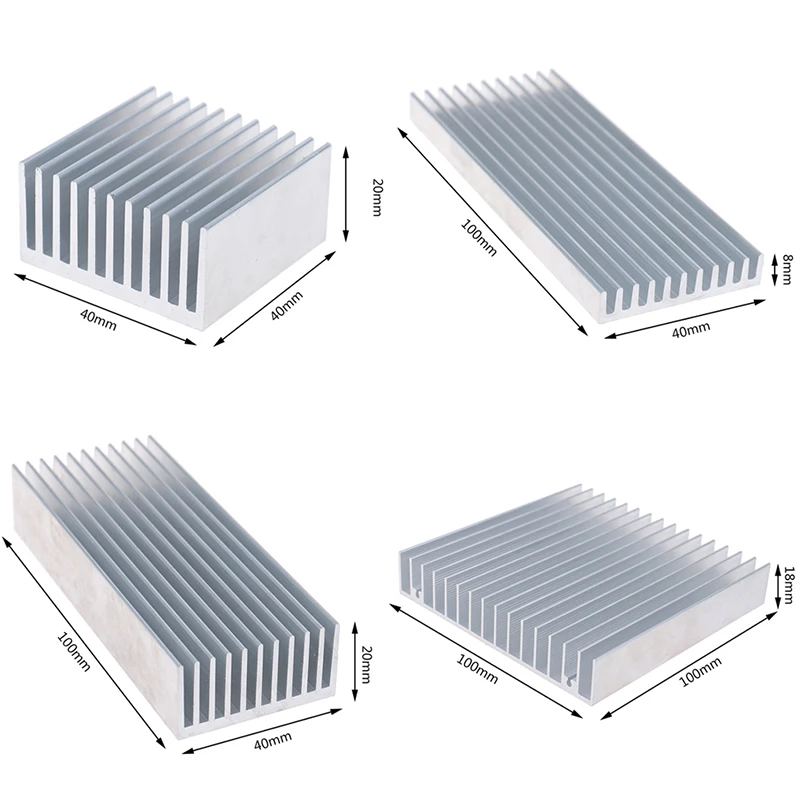

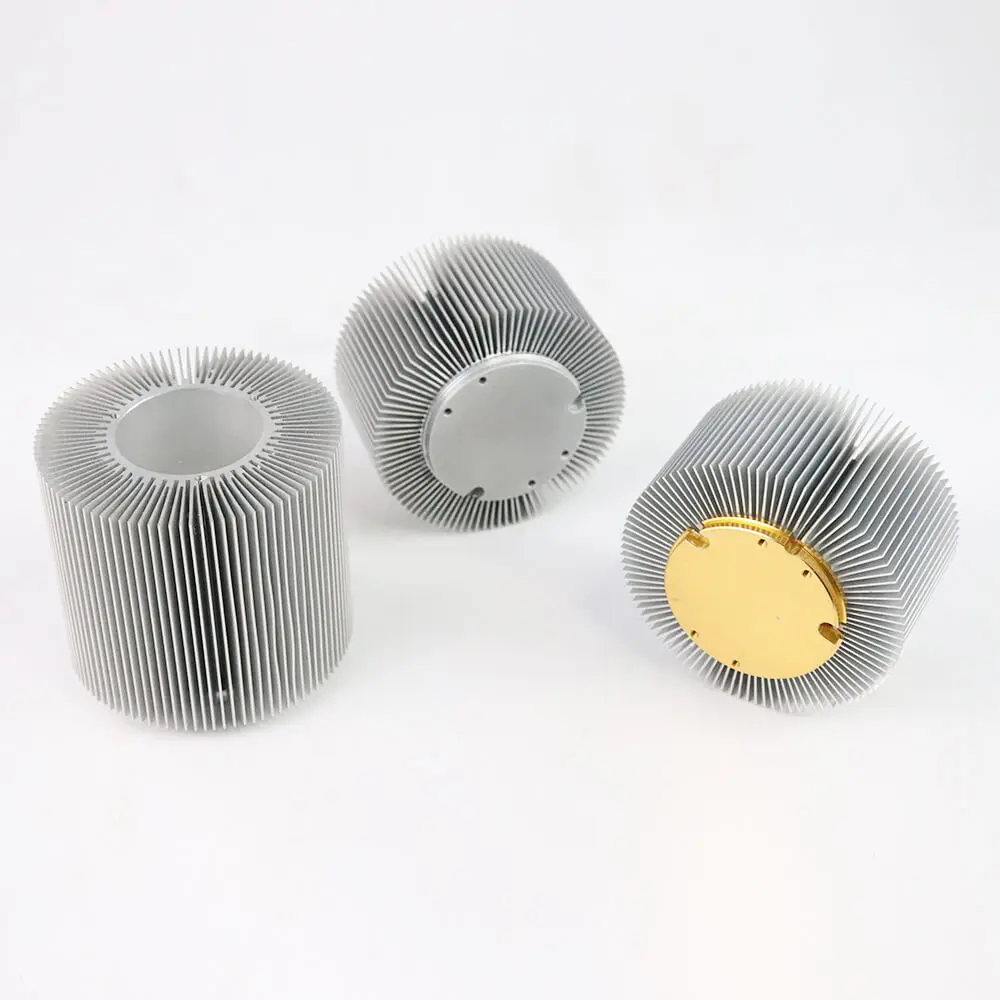

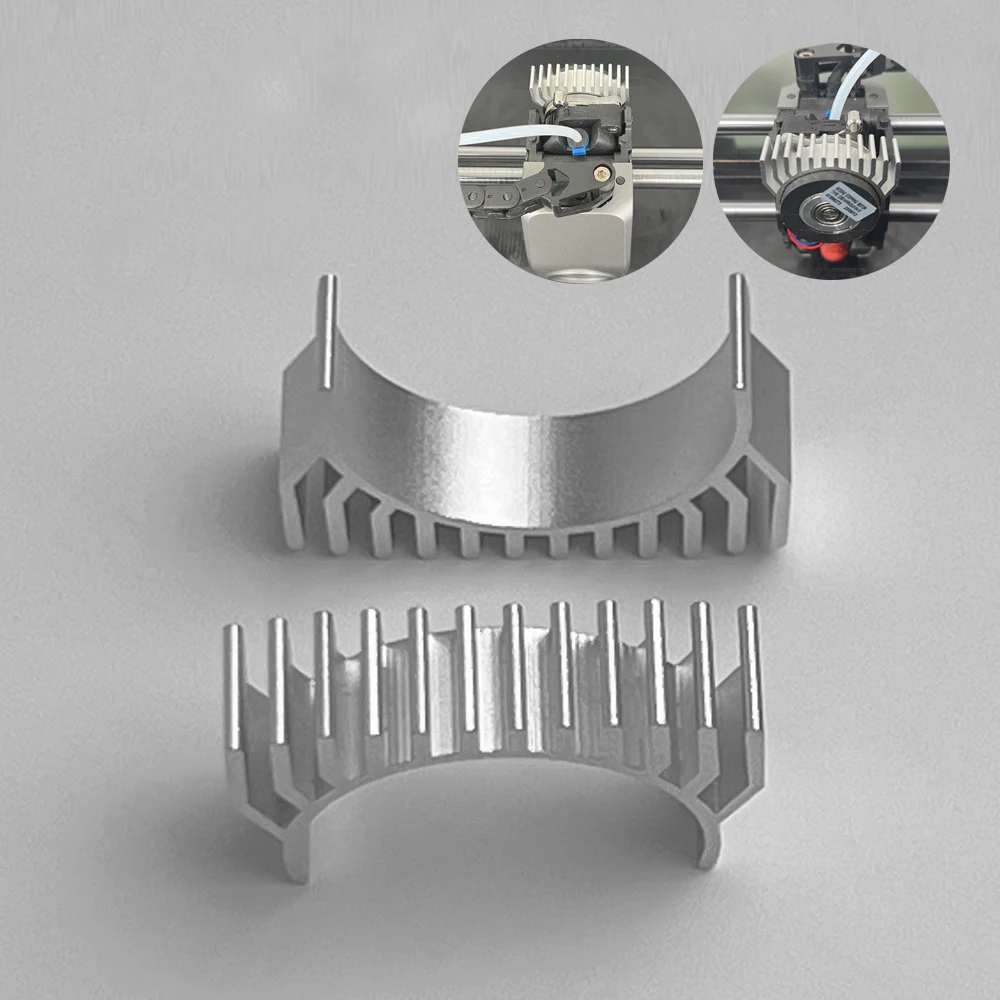

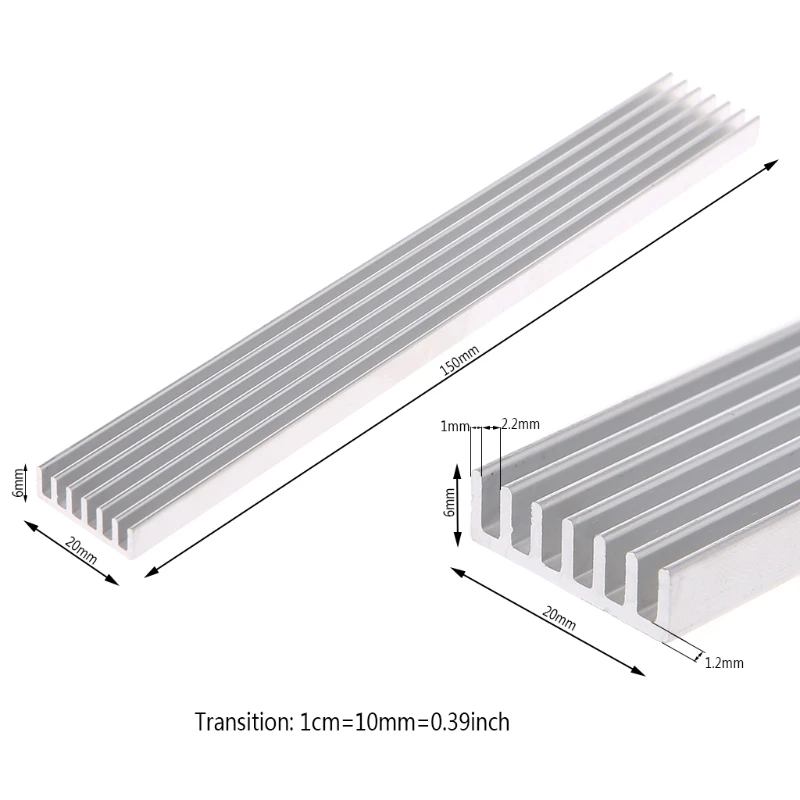

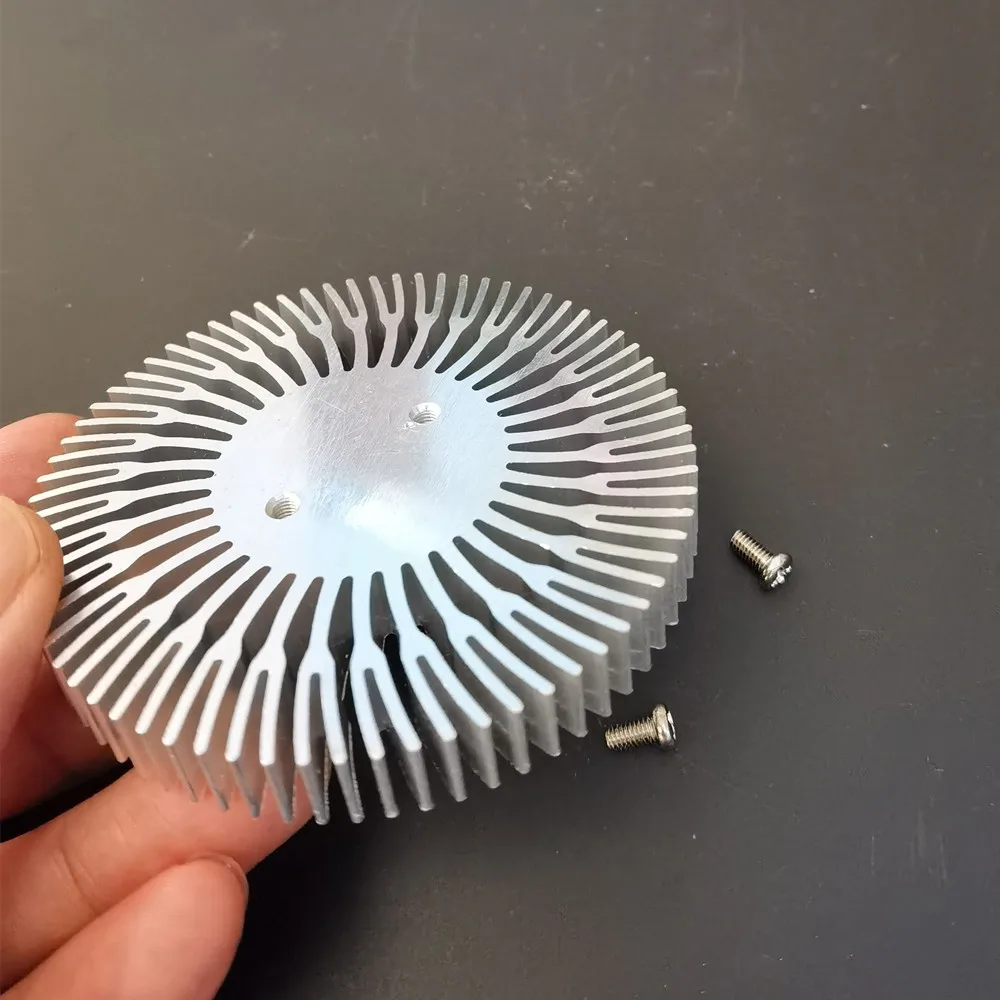

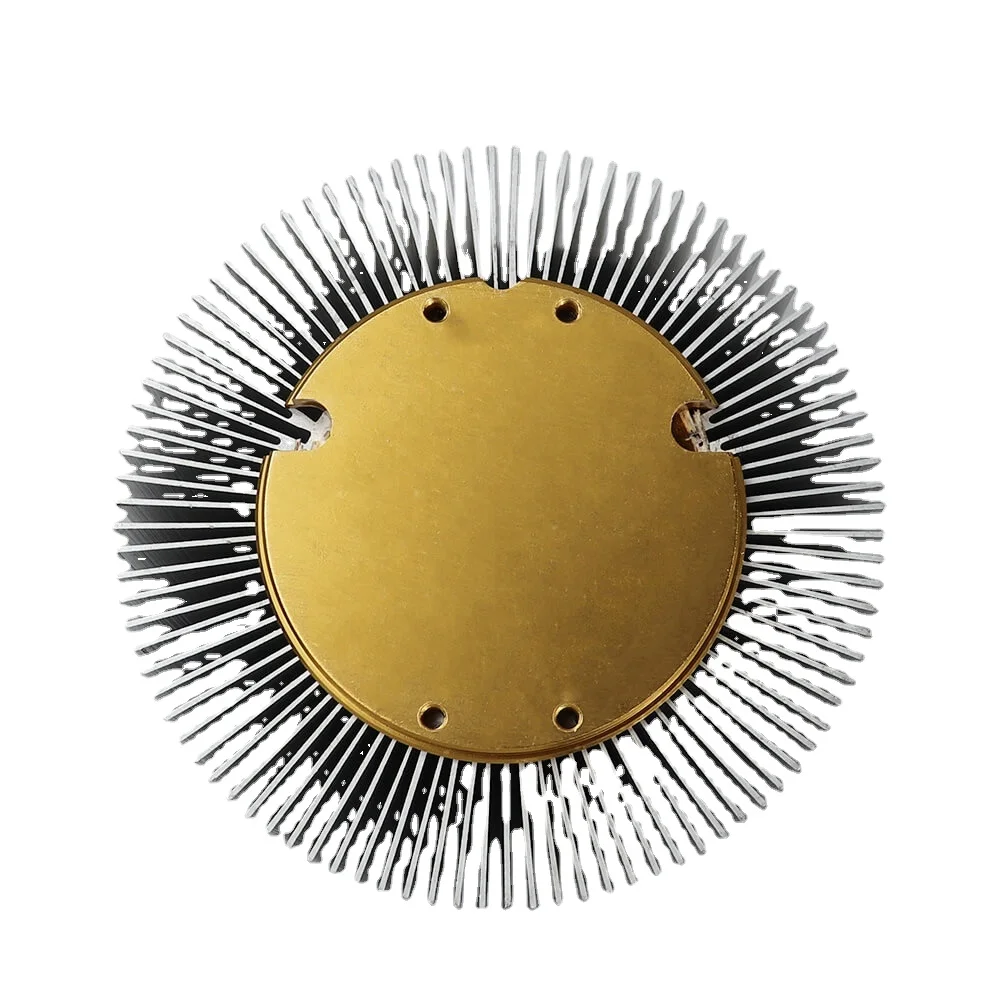

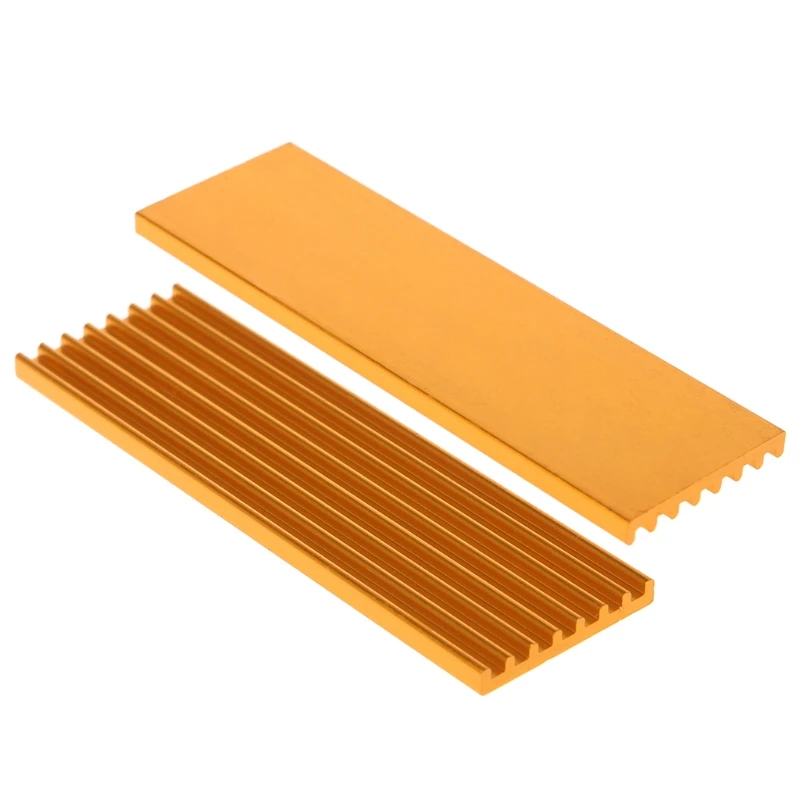

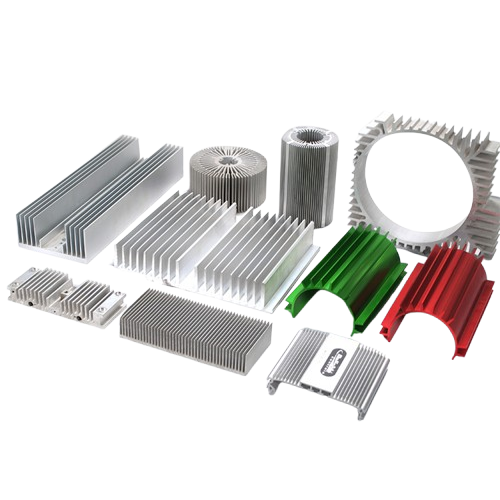

Aluminum Heat Sink

- CNC processing, the tolerance is controlled at ±0.05mm to ensure precise matching.

- The cost of aluminum is 30% lower than that of copper, which improves production economy.

- The thermal conductivity of aluminum is as high as 200 W/m·K, which dissipates heat quickly.

- Aluminum heat sinks are about 60% lighter than steel, reducing the weight of equipment.

- After anodizing, the corrosion resistance of the aluminum surface is improved to 300 hours of salt spray test without damage.

Manufacturer

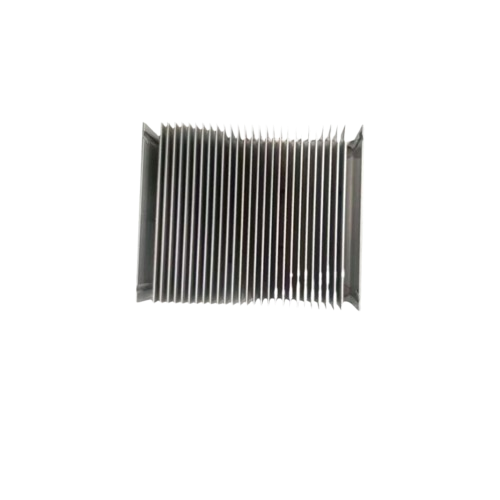

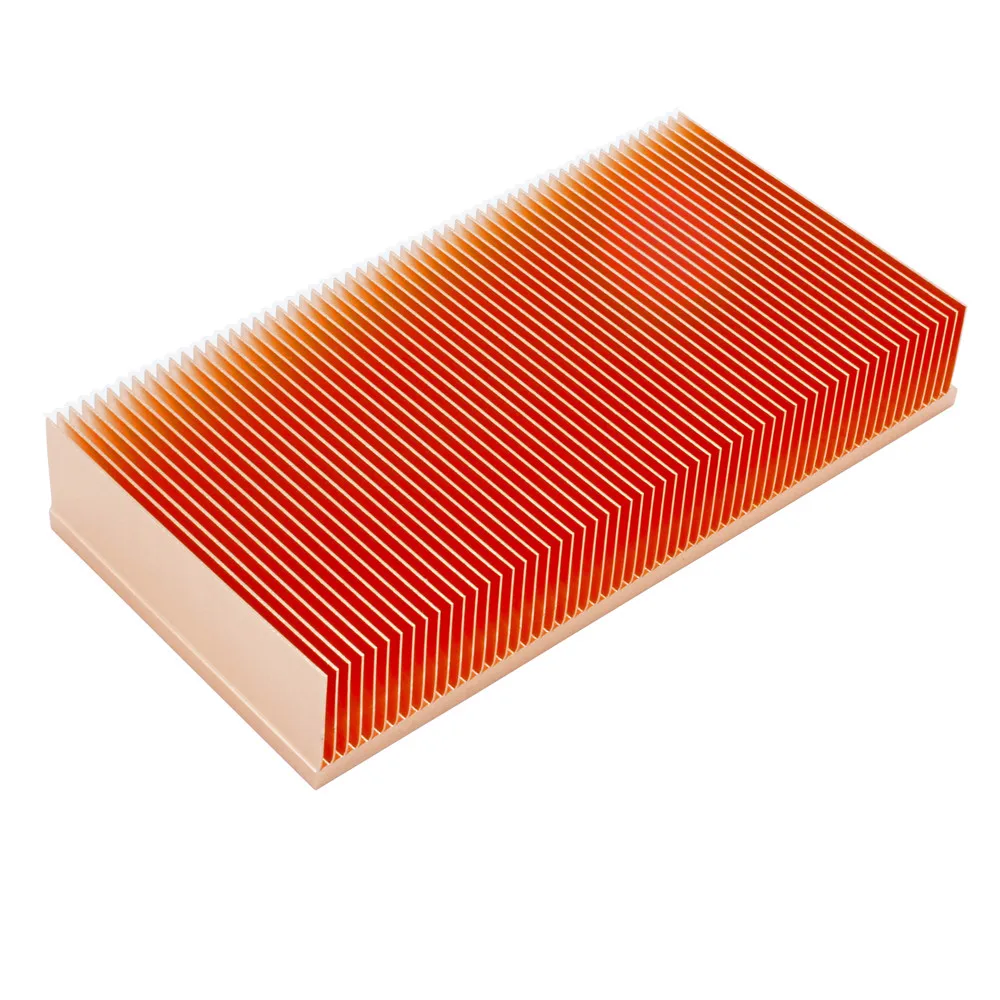

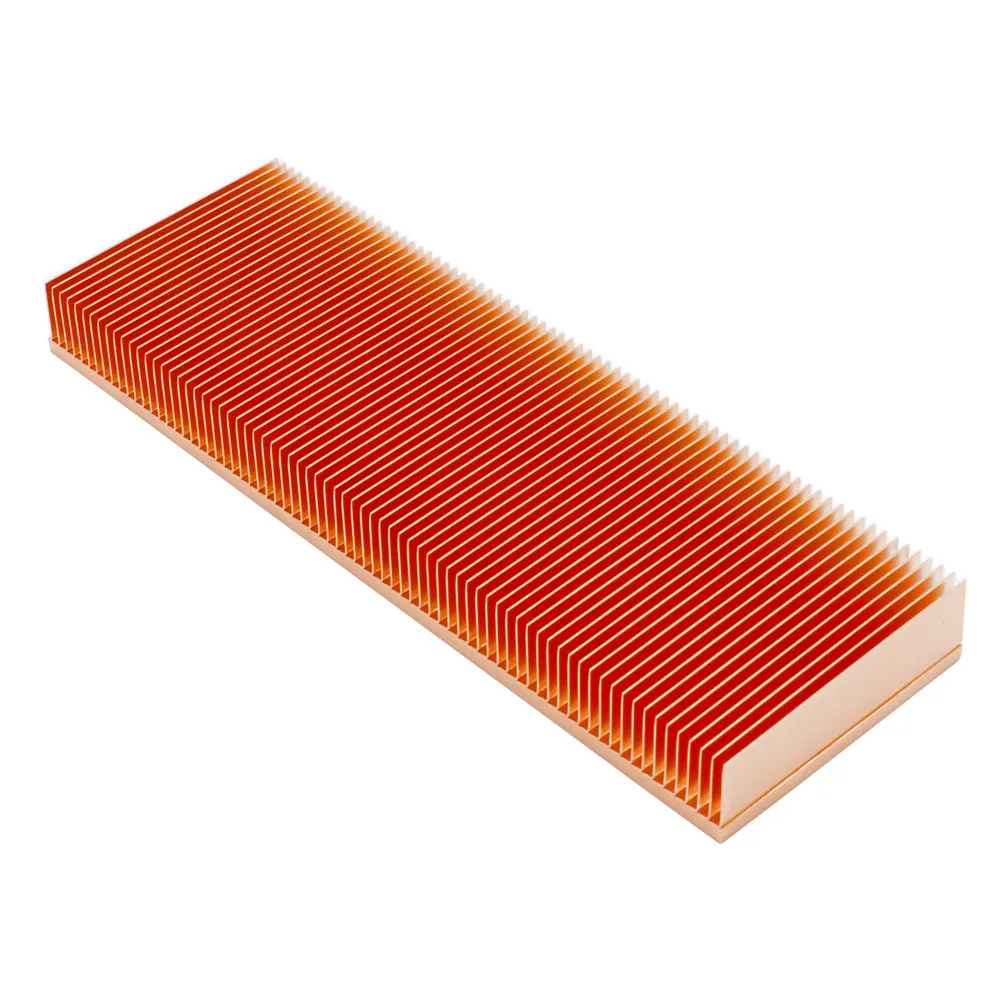

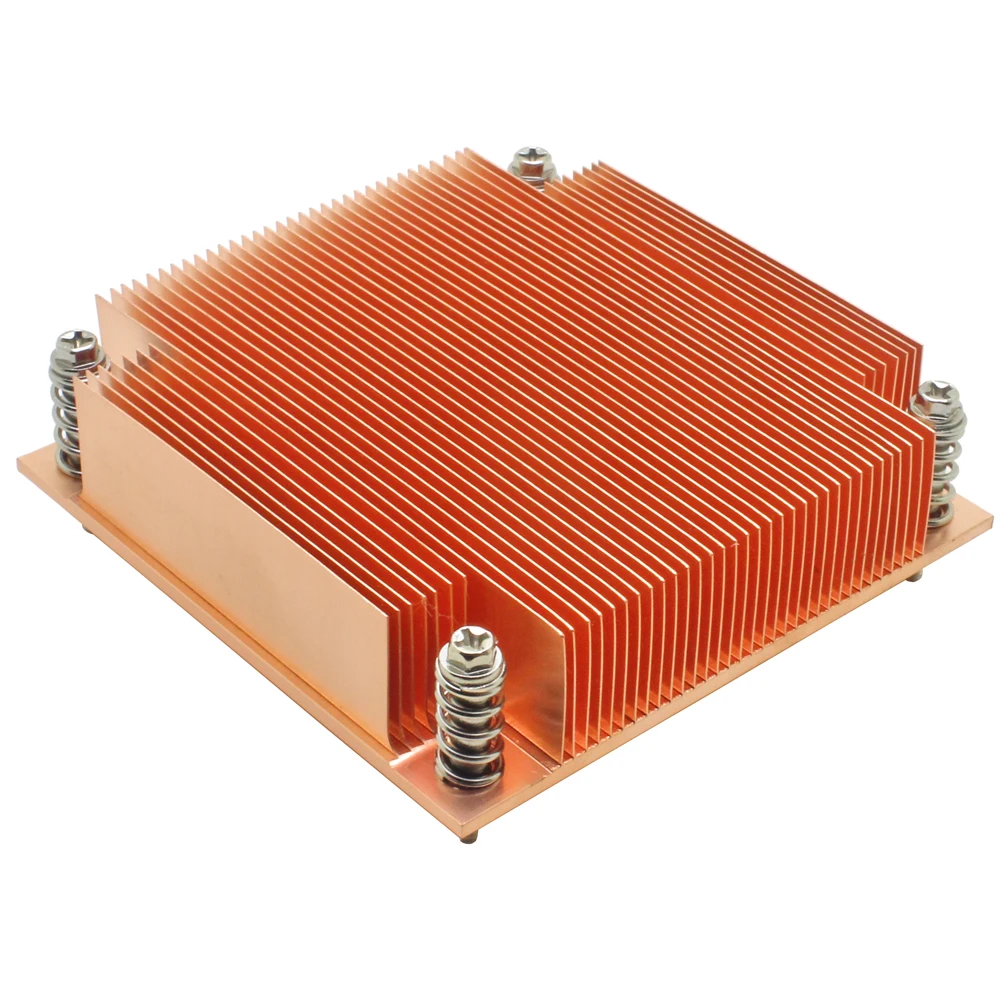

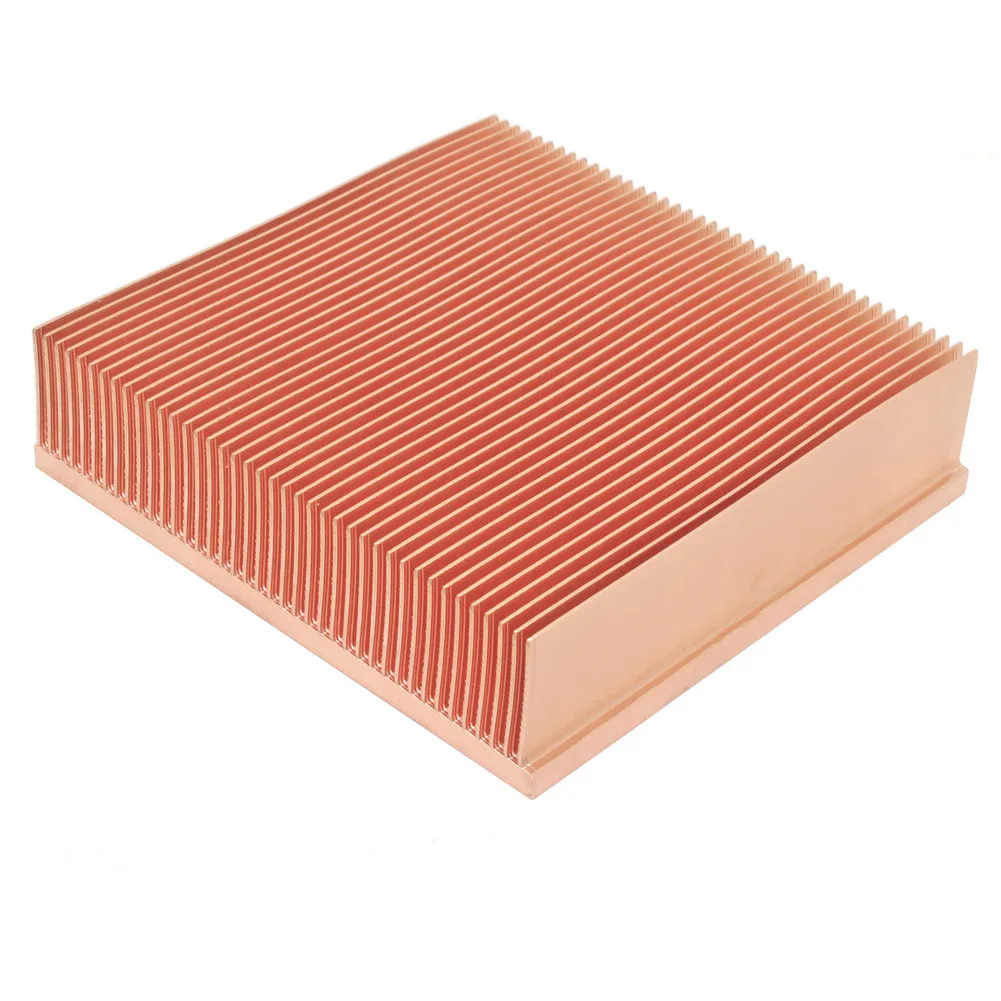

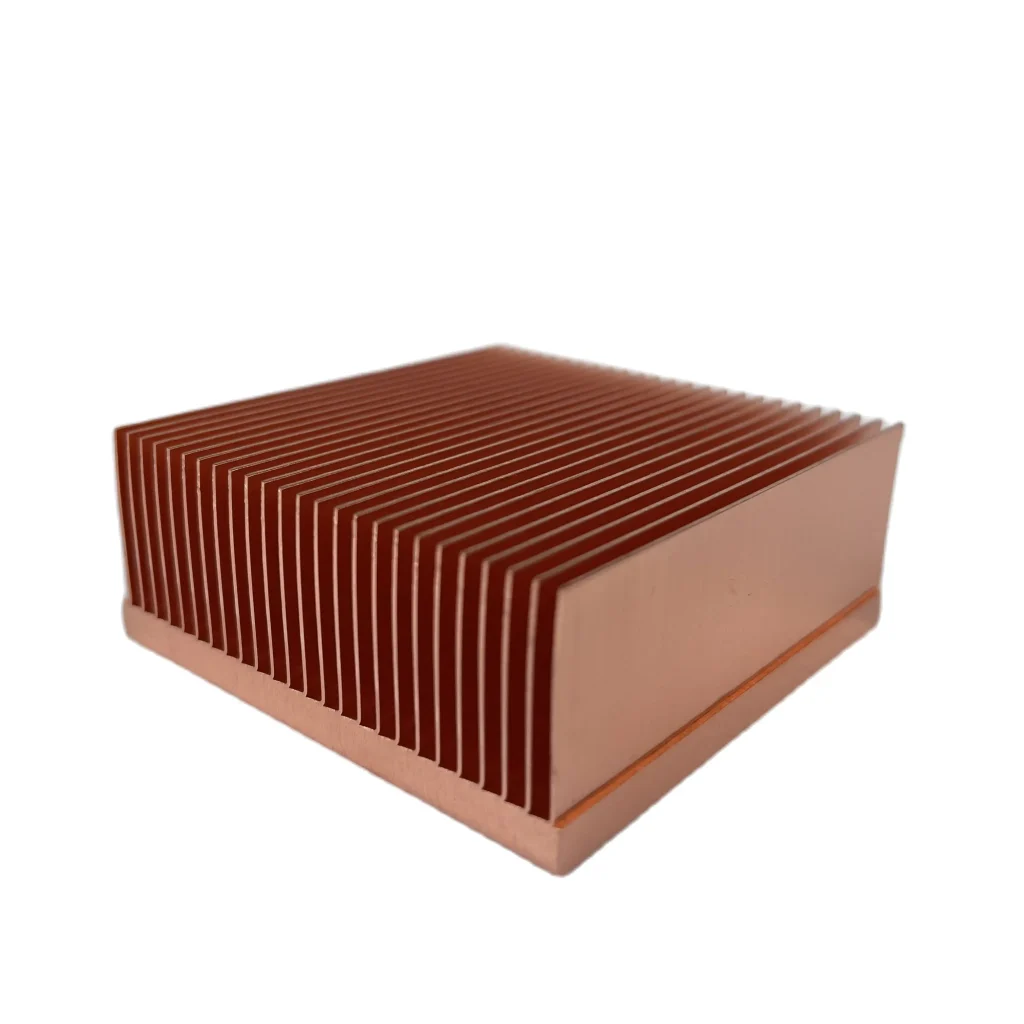

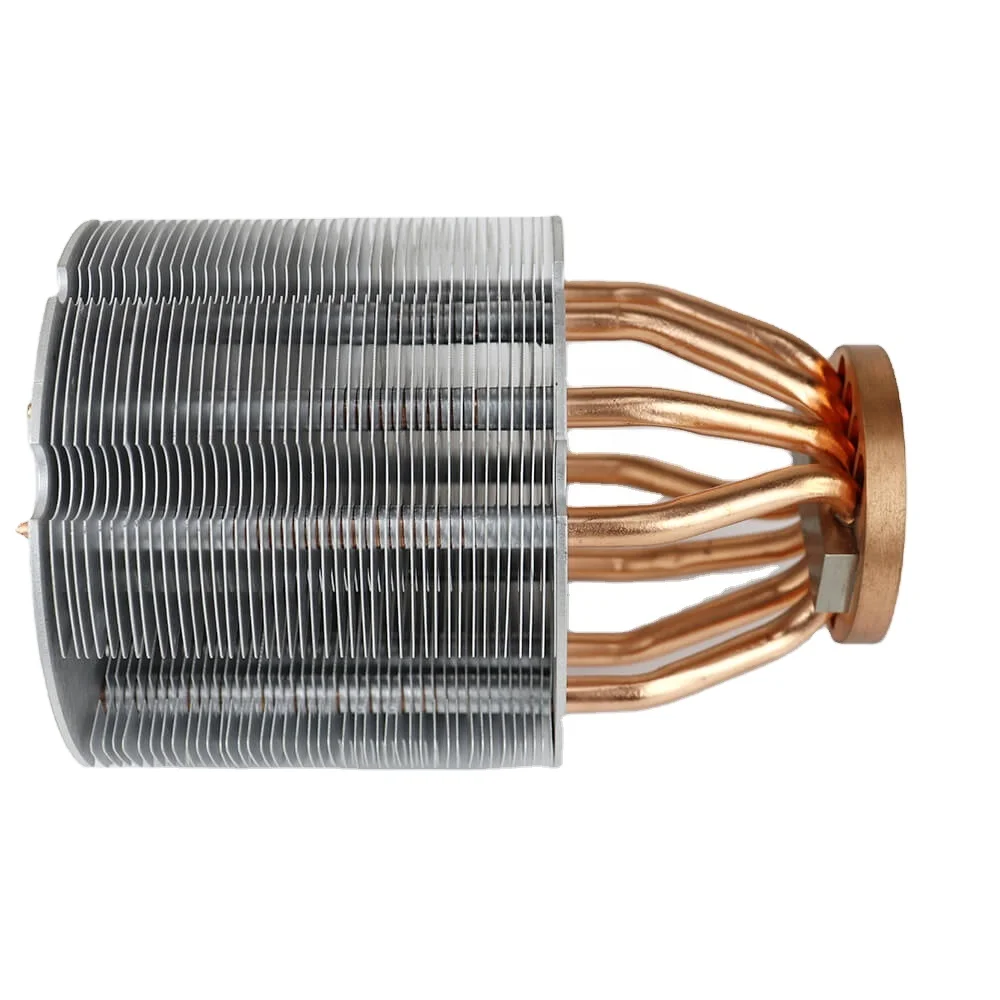

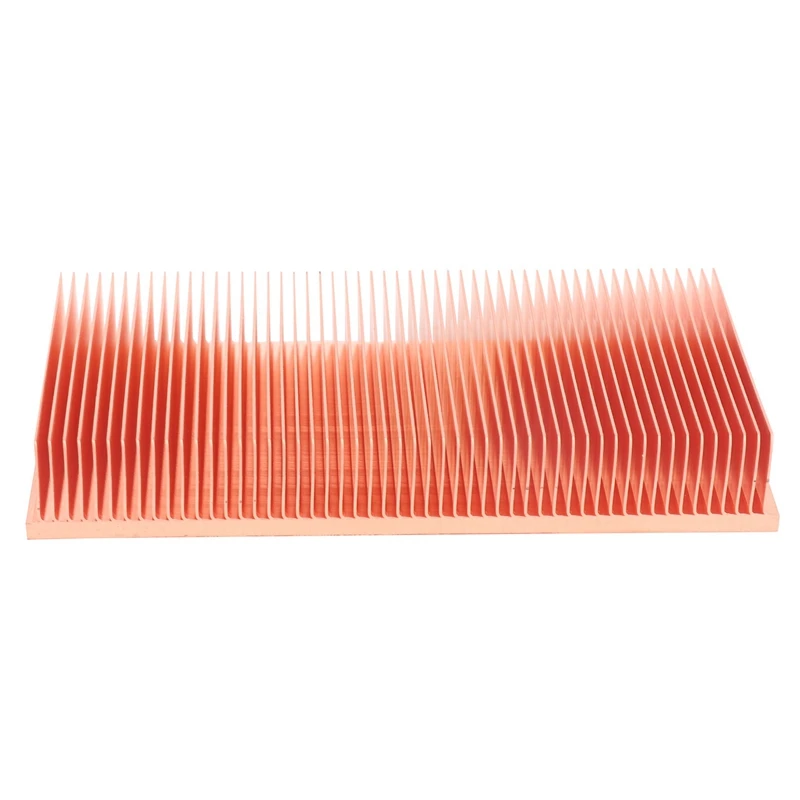

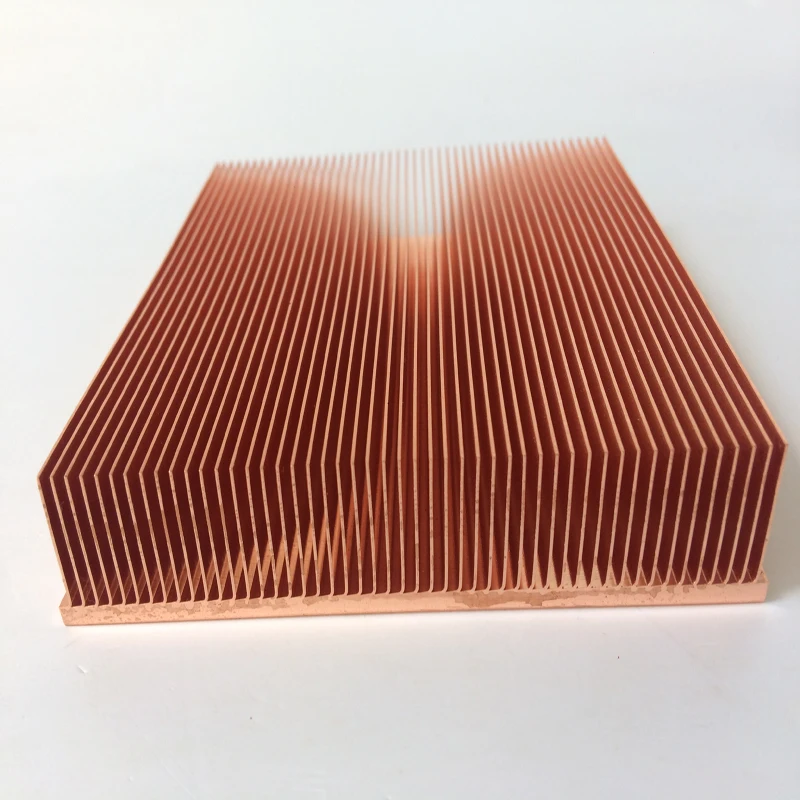

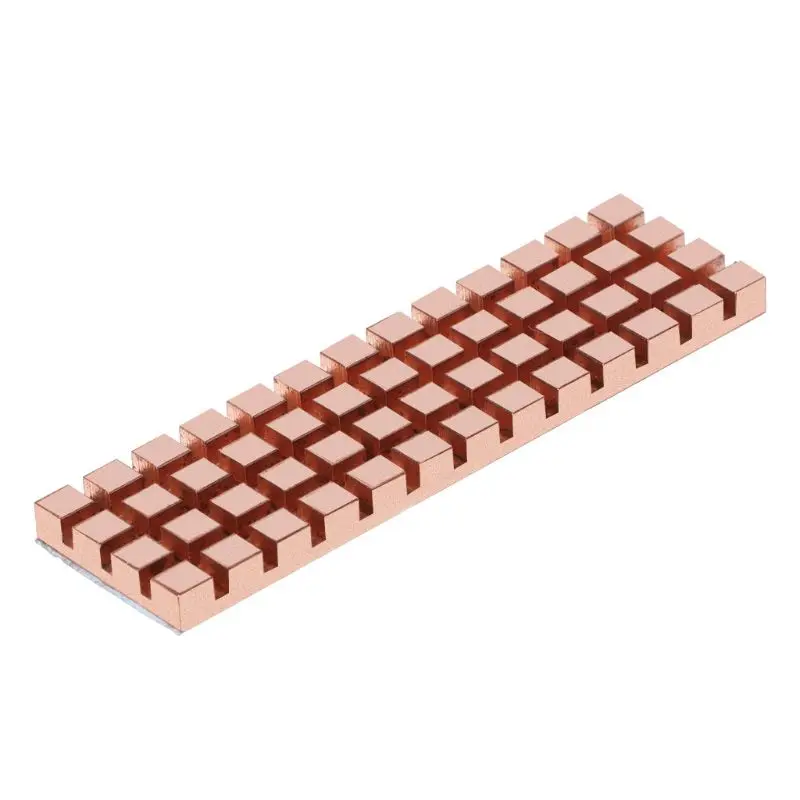

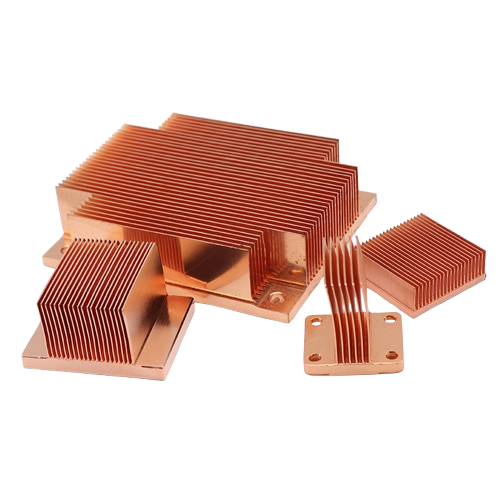

Copper Heat Sink

- CNC processing, tolerance control within ±0.05mm, to ensure precision.

- The cost of copper is 50-70% higher than that of aluminum, suitable for high-end applications.

- Copper has a thermal conductivity of up to 380 W/m·K, providing faster heat dissipation.

- About 2.5 times heavier than aluminum, suitable for high heat dissipation requirements.

- A protective oxide layer is formed on the surface of copper, which has good corrosion resistance.

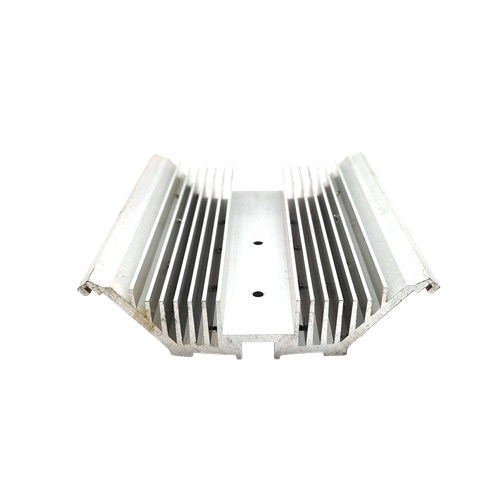

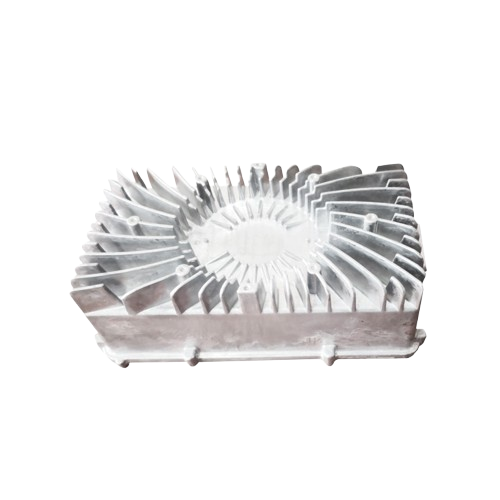

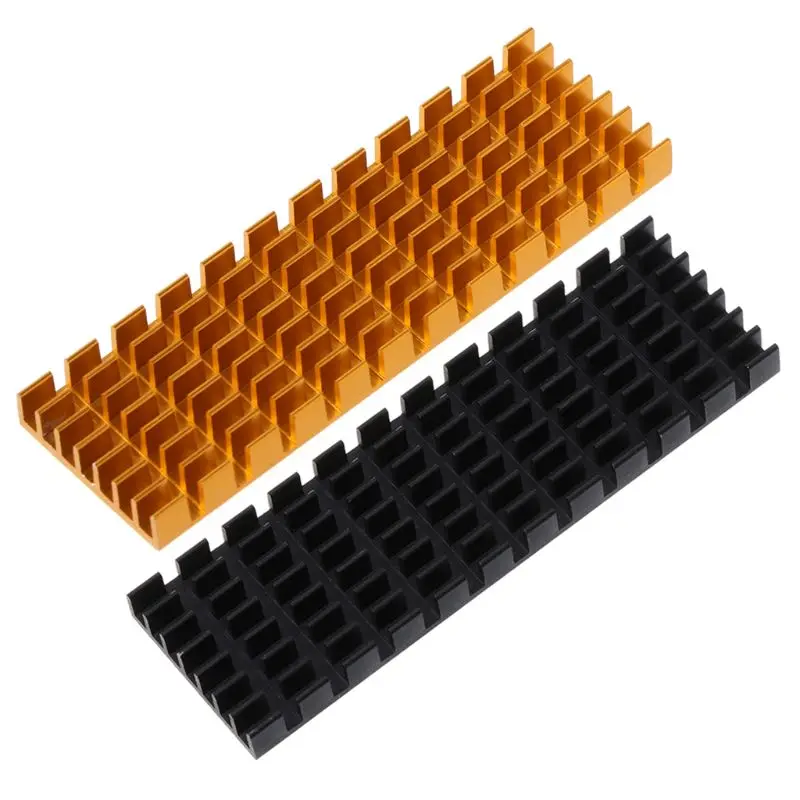

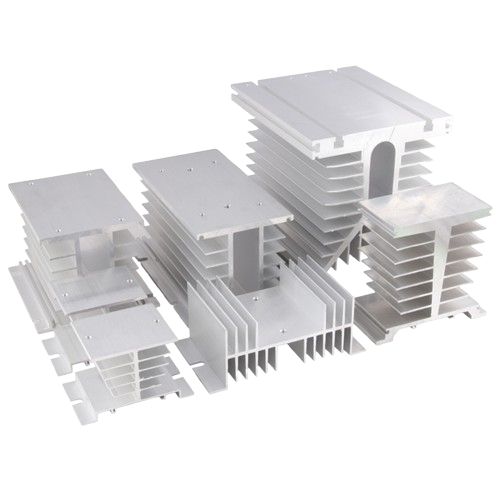

Custom Heat Sinks

Our custom heat sinks are flexible in design and can provide solutions for sizes ranging from small devices to large industrial equipment.

Size Range: From 30mm to 600mm, covering all cooling needs from precision electronic devices to large mechanical systems.

Custom Design: Whether it is a micro heat sink or a large size heat sink, we can provide customers with tailored sizes to ensure a perfect fit and provide optimal cooling effect.

We offer a wide range of material options to meet the special needs of different devices for thermal management and ensure that the heat sink can provide the best thermal conductivity.

Aluminum Alloy: Widely used in most electronic devices, with excellent thermal conductivity and lightness.

Copper: Better thermal conductivity, suitable for high-power, high-heat load devices, can efficiently conduct heat.

Aluminum-Magnesium Alloy: With excellent strength and lightweight characteristics, it is suitable for applications requiring high strength.

Other Materials: We also provide a variety of materials such as stainless steel, graphite, titanium alloy, plastic composite materials, etc., which can be customized according to the specific needs of customers.

We use advanced manufacturing processes and high-precision machining techniques to ensure the best performance of custom heat sinks.

Cold forging: Provides high strength and pressure resistance for high-strength applications.

Extrusion: Efficiently produces aluminum alloy heat sinks to ensure consistency and cost-effectiveness.

Die casting: Manufactures complex structure heat sinks, especially suitable for the precise production of copper or aluminum alloys.

Cutting: CNC precision machining to meet high-precision or small-batch customization needs.

Surface treatment: Anodizing, spraying and other treatments to improve corrosion resistance and optimize heat dissipation performance.

Thermal simulation and optimization design: Ensure the best thermal management effect of the heat sink through thermal analysis.

Heat sink industry application

Battery management system, LED headlights, automotive ECU heat sinks

Solar inverter, wind turbine electronic control system, energy storage battery pack heat sink

CPU, GPU, server equipment heat sinks

LED lamps, outdoor advertising screen heat sinks

Base station, 5G communication equipment, router and switch heat sinks

Servo motor, PLC control system, industrial robot power heat sink

CT machine power module, MRI equipment, ultrasonic scanner heat sink

Aircraft electronic system, satellite communication module, navigation equipment heat sink

Power module heat sinks for power adapters, inverters, UPS power supplies and other equipment

Air conditioning control module, refrigerator compressor, washing machine motor heat sink

Ready to receive a quote?

Simply fill out our inquiry form, and we’ll get back to you within 24 hours. The more details you provide, the more accurate and tailored your quote will be. Don’t hesitate – get started today and let us help you with your project!