Reduction Gears

- Reduction Gears Manufacturer Price, cost reduction of 30%

- Custom Reduction Gears according to drawings

- No MOQ

We are an industry-leading reduction gear manufacturer, committed to providing high-quality, high-performance reduction gear solutions to customers around the world. With years of professional experience and technological innovation, our products are widely used in various types of mechanical equipment, helping customers achieve efficient and reliable power transmission.

Why do we need reduction gears?

In modern industrial and automation equipment, motors are the core power source. However, the speed and torque of most motors have a fixed operating range and are usually in their most efficient working state. When the actual working demand is lower than the output speed and torque of the motor, direct drive will not only lead to reduced efficiency, but may also cause problems such as overheating and shortened equipment life. At this time, reduction gears become a key component to solve this problem.

Reduction gears reduce the output speed of the motor while increasing the torque, allowing the motor to operate within its optimal efficiency range. Choosing the right gear ratio can accurately match the working requirements and achieve efficient and stable power transmission, thereby avoiding the use of larger and more expensive motors, saving costs and improving equipment performance.

Wide application of reduction gears

Reduction gears are widely used in various precision control and power transmission occasions due to their unique performance advantages. Here are some of the main application areas:

Mobile devices: such as elevators and escalators, reduction gears ensure smooth and safe operation.

Factory devices: Equipment such as conveyor belts and industrial robots rely on reduction gears for efficient and precise operation.

Automation devices: Intelligent devices such as automatic doors and automatic blinds achieve sensitive response and control through reduction gears.

Precision devices: In medical equipment, measuring instruments, and optical equipment, reduction gears provide the necessary accuracy and stability.

Whether it is automatic equipment in daily life or high-end machinery in industrial production, reduction gears are an indispensable key component. [Company Name] has become the preferred partner of many industry customers with its excellent product quality and professional technical support.

Our reduction gear manufacturing advantages

High-quality manufacturing: Using advanced production processes and strict quality control to ensure that each reduction gear meets the highest standards.

Customized solutions: Provide personalized design and manufacturing services according to the specific needs of customers to meet diverse application scenarios.

Professional technical team: With an experienced team of engineers, we provide customers with comprehensive technical support and after-sales service.

Continuous innovation: Continuously invest in research and development to promote the advancement of reduction gear technology and maintain industry leadership.

If you are interested in our reduction gear products or services, please feel free to contact us. We look forward to working with you to create a brilliant future!

- Jump to Section

- Workshop

- Material

- Advantages

- Faq

- Process

- Applications

- Finished product

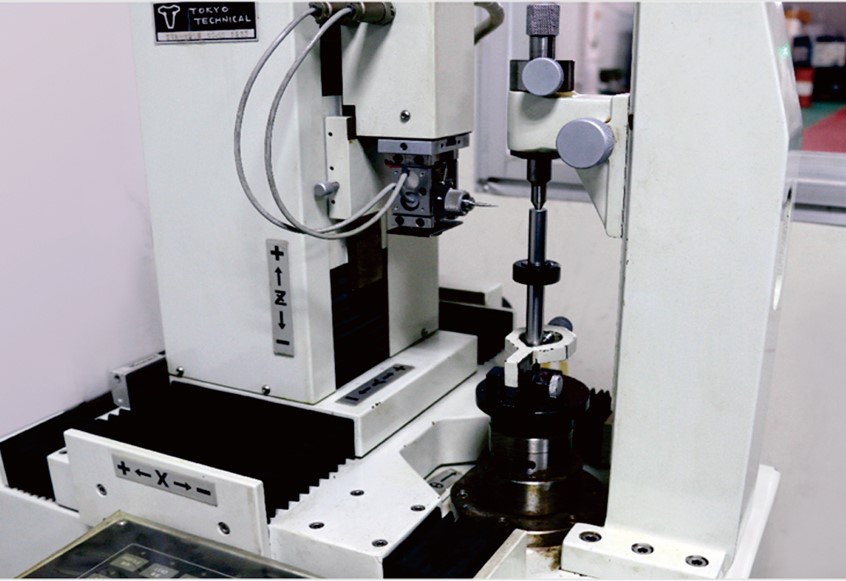

Reduction Gears Manufacturer Workshop

Reduction Gears Material Selection

- Carbon Steel

- Alloy Steel

- Stainless Steel

- Cast Iron

- Aluminum Alloys

- Brass and Bronze

- Nylon

- Acetal

- Polycarbonate

- Peek

- Glass-Fiber Reinforced Plastics

Why Choose Us

Frequently ask question

Yes, we provide custom gear solutions based on your specific requirements, including Custom Gears, Plastic Gears, Internal Gears, and more.

Our prices are highly competitive, helping customers save up to 30% on costs while maintaining top-quality standards.

Our gears are widely used in automotive, machinery, electronics, medical devices, and various other industries, meeting specific customer needs.

We offer fast turnaround times, typically completing production and delivery within 7 days, ensuring your projects stay on schedule.

We have advanced manufacturing equipment and strict quality control processes. All products undergo precise testing to meet international standards.

Yes, we welcome customers from all over the world to visit our factory to see our manufacturing capabilities and quality control processes firsthand.

Yes, we provide reliable global shipping services to ensure timely delivery to your location, wherever you are.

We offer a wide range of gears, including Helical Gears, Bevel Gears, Worm Gears, Screw Gears, and more, catering to diverse application needs.

Our technical support team is available to assist you in selecting the best gear type and specifications based on your application requirements.

Yes, we can accommodate small batch custom production, meeting the needs of customers with different production scales while ensuring fast delivery.

Reduction Gears Processing Process

Our company’s gear manufacturing process undergoes strict quality control and advanced technical support to ensure that each gear has high precision and high performance.

Applications

- Automotive

- Construction

- Electrical

- Electronics

- Heavy Equipment

- Industrial Machinery

- Marine

- Medical Devices

- Off-Highway

- Pneumatics

Services

-

Casting

-

Climb Hobbing

-

Conventional Hobbing

-

Forging

-

Grinding

-

Heat Treating

-

Honing

-

Flame Cutting

-

Lapping

-

Milling

-

Shaping

-

Shaving

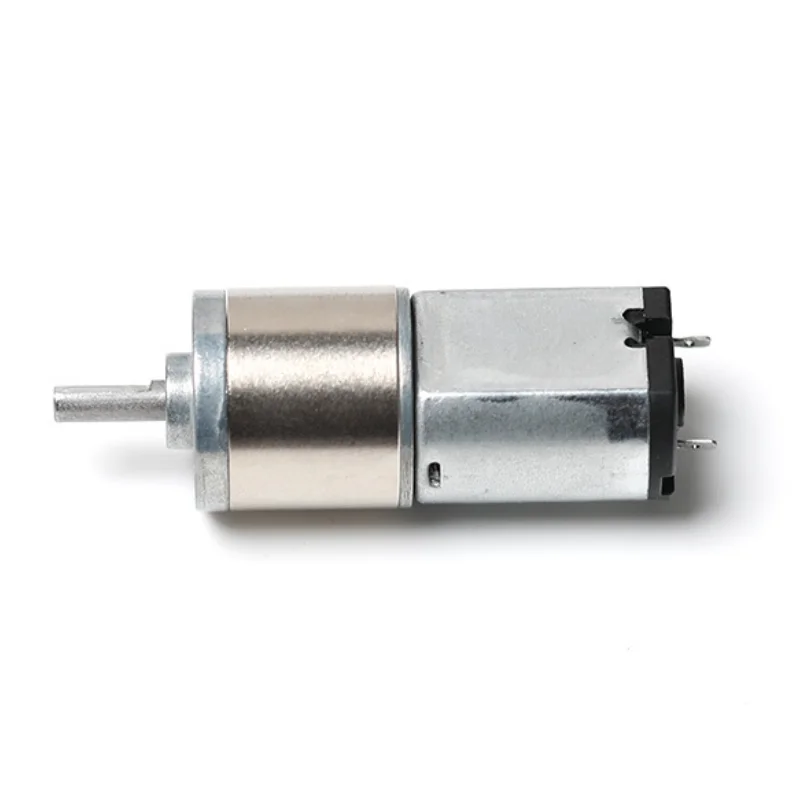

Finished Reduction Gears Display

Reduction Gears Manufacturing Service Experts

The types of gears we produce include: