Hypoid Gears

- Hypoid Gears Manufacturer Price, cost reduction of 30%

- Custom Hypoid Gears according to drawings

- No MOQ

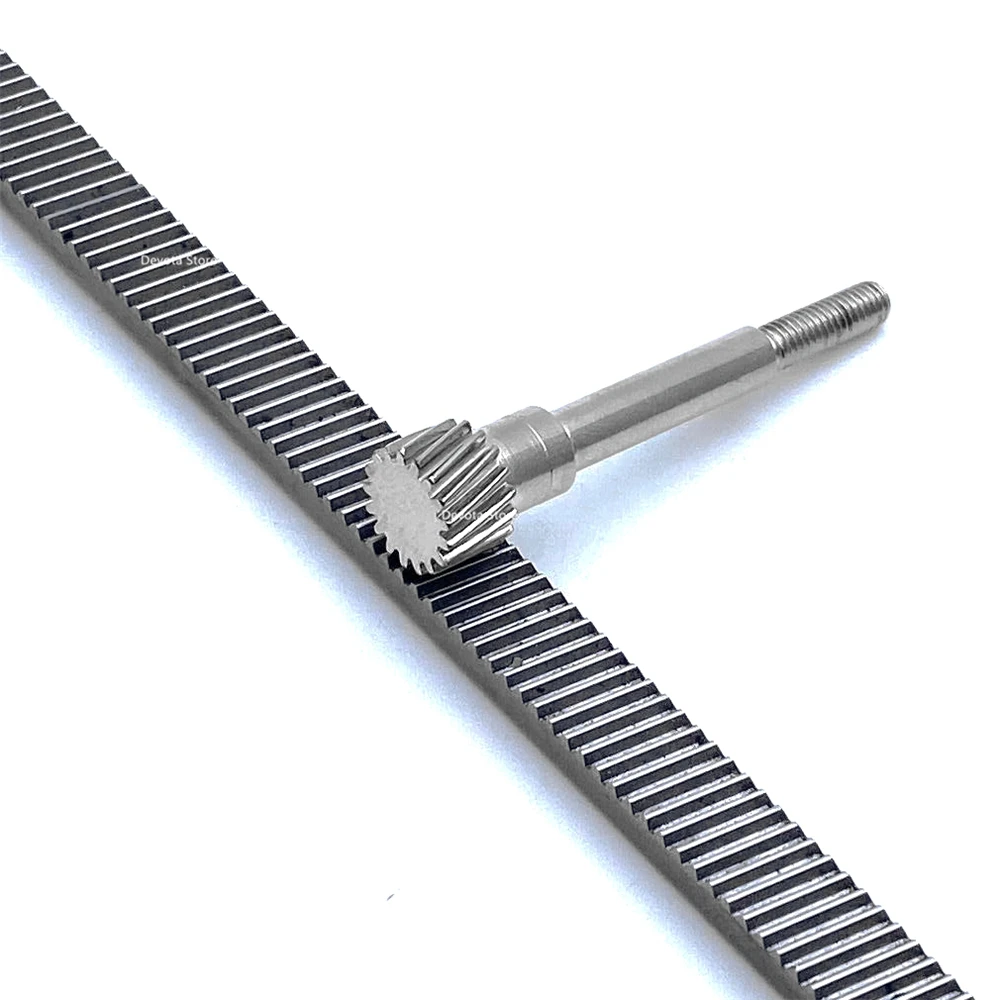

We are a specialized manufacturer of hypoid gears, dedicated to delivering high-performance, precision-engineered gears that meet the needs of various industrial applications. hypoid gears, similar to spiral bevel gears, feature a unique geometric design that provides higher load capacity, smoother operation, and reduced noise levels. Our products are widely used in industries such as automotive, aerospace, machinery, and heavy equipment.

Product Features of hypoid gears

Unique Design: hypoid gears are designed with offset axes, which allows for greater torque transmission compared to spiral bevel gears.

High-Efficiency Transmission: Due to their special engagement design, hypoid gears operate smoothly at higher speeds, making them ideal for applications requiring high torque and low noise.

Reduced Noise and Vibration: With larger contact surfaces, hypoid gears provide softer engagement, which significantly reduces noise and vibration, making them suitable for systems where quiet operation is critical.

Our hypoid gears Manufacturing Capabilities

Custom Design and Production: We have strong design and manufacturing capabilities, allowing us to custom-produce hypoid gears in various sizes and specifications according to specific customer requirements.

Complex Shape Production: hypoid gears have complex geometries, and we ensure precision in every detail through advanced CNC machining equipment and skilled technicians.

Mass and Small-Batch Production: Whether you require large-scale industrial production or small-batch orders for special applications, we can meet your needs with efficient production processes.

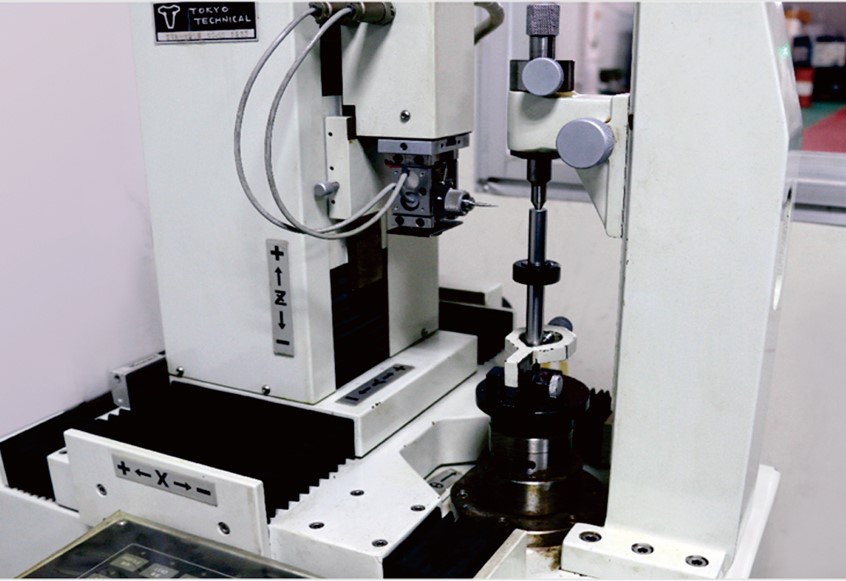

Advanced Equipment and Technology

High-Precision Machining Equipment: We utilize world-class CNC equipment for precision cutting and grinding of hypoid gears, ensuring that each gear meets the highest accuracy standards.

Versatile Production Lines: Our production lines handle the complexity of Hypoid gear designs and also offer heat treatment, surface finishing, and other supplementary processes to ensure excellent wear resistance and long service life.

Automated Manufacturing Process: Through robotics and automation technology, we enhance production efficiency and ensure product consistency and quality with minimal manual intervention.

Quality Management and Certifications

Strict Quality Management: Our Hypoid gear manufacturing process is ISO 9001:2015 certified, and every product undergoes rigorous quality inspections to ensure compliance with international standards for performance and durability.

Comprehensive Quality Control: From raw material selection to final product testing, our quality control system covers every stage of production, ensuring that our gears can perform reliably under various challenging conditions.

Customer Support and Services

Design and Technical Support: Our expert technical team is available to support customers at every stage, from the initial design phase to the manufacturing process, providing optimized gear solutions tailored to specific needs.

Fast Response and Global Delivery: With flexible production capabilities and a global logistics network, we ensure that customers receive their custom Hypoid gear products in the shortest possible time, no matter where they are located.

Customized Solutions: Whether you are looking for replacement gears for existing equipment or designing new systems, we offer tailor-made gear solutions to ensure optimal performance.

We are committed to innovation and maintaining the highest quality standards to deliver top-performance hypoid gears. If you have any requirements for hypoid gears, our team is ready to provide you with professional solutions tailored to your needs.

- Jump to Section

- Workshop

- Material

- Advantages

- Faq

- Process

- Applications

- Finished product

Hypoid Gears Manufacturer Workshop

Hypoid Gears Material Selection

- Carbon Steel

- Alloy Steel

- Stainless Steel

- Cast Iron

- Aluminum Alloys

- Brass and Bronze

- Nylon

- Acetal

- Polycarbonate

- Peek

- Glass-Fiber Reinforced Plastics

Why Choose Us

Frequently ask question

Yes, we provide custom gear solutions based on your specific requirements, including Custom Gears, Plastic Gears, Internal Gears, and more.

Our prices are highly competitive, helping customers save up to 30% on costs while maintaining top-quality standards.

Our gears are widely used in automotive, machinery, electronics, medical devices, and various other industries, meeting specific customer needs.

We offer fast turnaround times, typically completing production and delivery within 7 days, ensuring your projects stay on schedule.

We have advanced manufacturing equipment and strict quality control processes. All products undergo precise testing to meet international standards.

Yes, we welcome customers from all over the world to visit our factory to see our manufacturing capabilities and quality control processes firsthand.

Yes, we provide reliable global shipping services to ensure timely delivery to your location, wherever you are.

We offer a wide range of gears, including Helical Gears, Bevel Gears, Worm Gears, Screw Gears, and more, catering to diverse application needs.

Our technical support team is available to assist you in selecting the best gear type and specifications based on your application requirements.

Yes, we can accommodate small batch custom production, meeting the needs of customers with different production scales while ensuring fast delivery.

Hypoid Gears Processing Process

Our company’s gear manufacturing process undergoes strict quality control and advanced technical support to ensure that each gear has high precision and high performance.

Applications

- Automotive

- Construction

- Electrical

- Electronics

- Heavy Equipment

- Industrial Machinery

- Marine

- Medical Devices

- Off-Highway

- Pneumatics

Services

-

Casting

-

Climb Hobbing

-

Conventional Hobbing

-

Forging

-

Grinding

-

Heat Treating

-

Honing

-

Flame Cutting

-

Lapping

-

Milling

-

Shaping

-

Shaving

Finished Hypoid Gears Display

Hypoid Gears Manufacturing Service Experts

The types of gears we produce include: