Gear Rack

- Gear Rack Manufacturer Price, cost reduction of 30%

- Custom Gear Rack according to drawings

- No MOQ

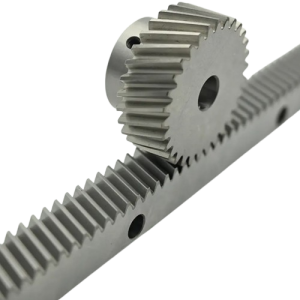

We are a precision gear rack manufacturer with over 10 years of experience, specializing in producing high-quality racks and drive components for applications such as instrumentation, servo drives, encoders, and power transmission. Our products offer reliable performance with the highest precision, designed to meet the demands of motion control systems. Additionally, we provide flexible customization services to meet the needs of various complex projects.

Gear Rack Product Features

| Parameter | Description |

|---|---|

| Rack Precision | AGMA Quality 8 or 10 |

| Materials | Primarily made from stress-relieved 416 stainless steel, with other materials available upon request |

| Pressure Angle | Standard 20-degree pressure angle,Customizable |

| Profile Options | Rectangular or round cross-section |

| Sizes | Available in both imperial and metric |

| Machining | Machined ends for seamless series assembly |

| Customization | Design, modification, prototyping, and custom production |

Customization Gear Rack Services

We offer complete customization services to design, modify, prototype, and produce racks and other mechanical drive components according to your specifications and application needs. Whether your project requires custom precision spur gear racks or other components, our engineering team is ready to produce parts that meet your performance requirements.

Contact Us

Are you looking for standard or custom precision gear racks to meet your performance needs? We manufacture stainless steel gear racks in various standard sizes and provide custom services for non-standard applications. Request a quote for precision spur gear racks or contact us to discuss your custom component requirements!

- Jump to Section

- Workshop

- Material

- Advantages

- Faq

- Process

- Applications

- Finished product

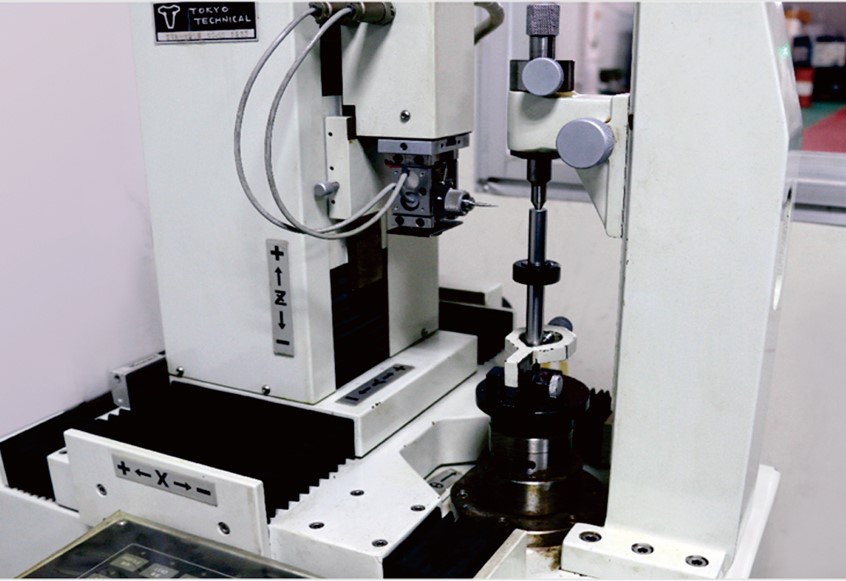

Gear Rack Manufacturer Workshop

Gear Rack Material Selection

- Carbon Steel

- Alloy Steel

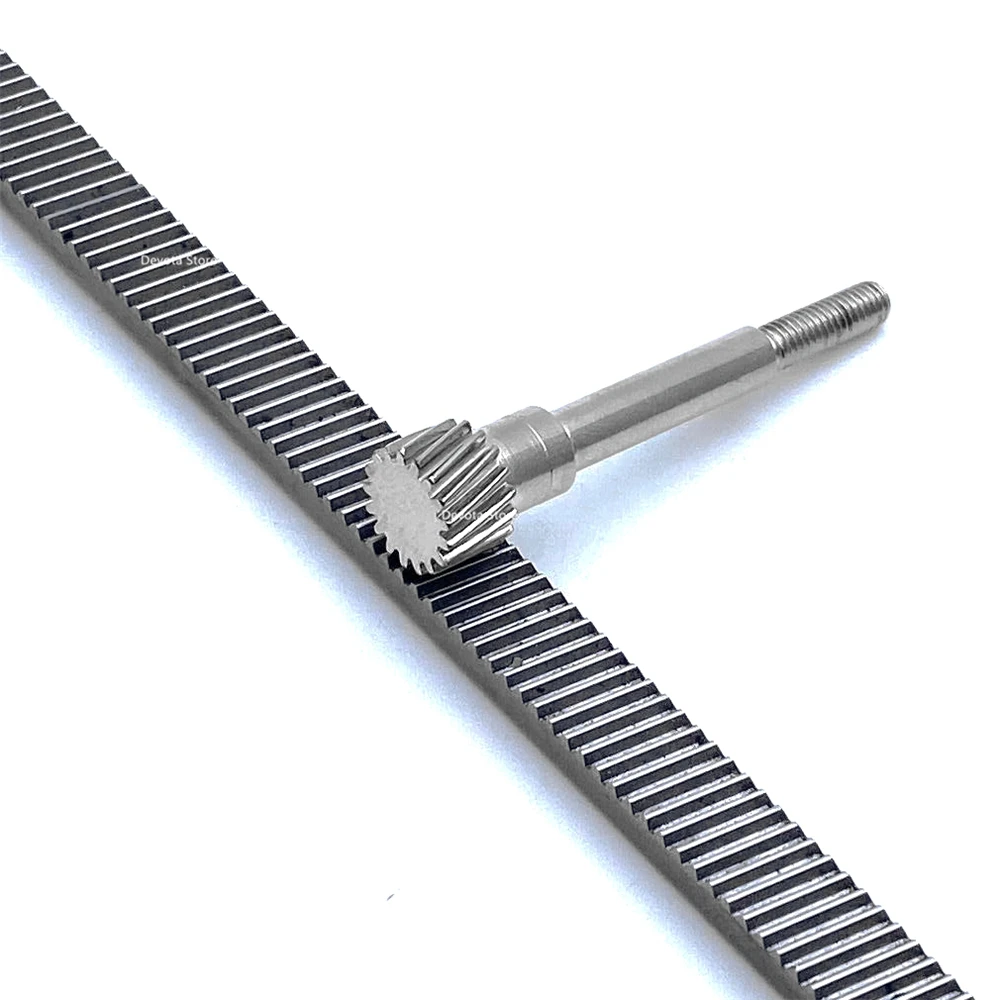

- Stainless Steel

- Cast Iron

- Aluminum Alloys

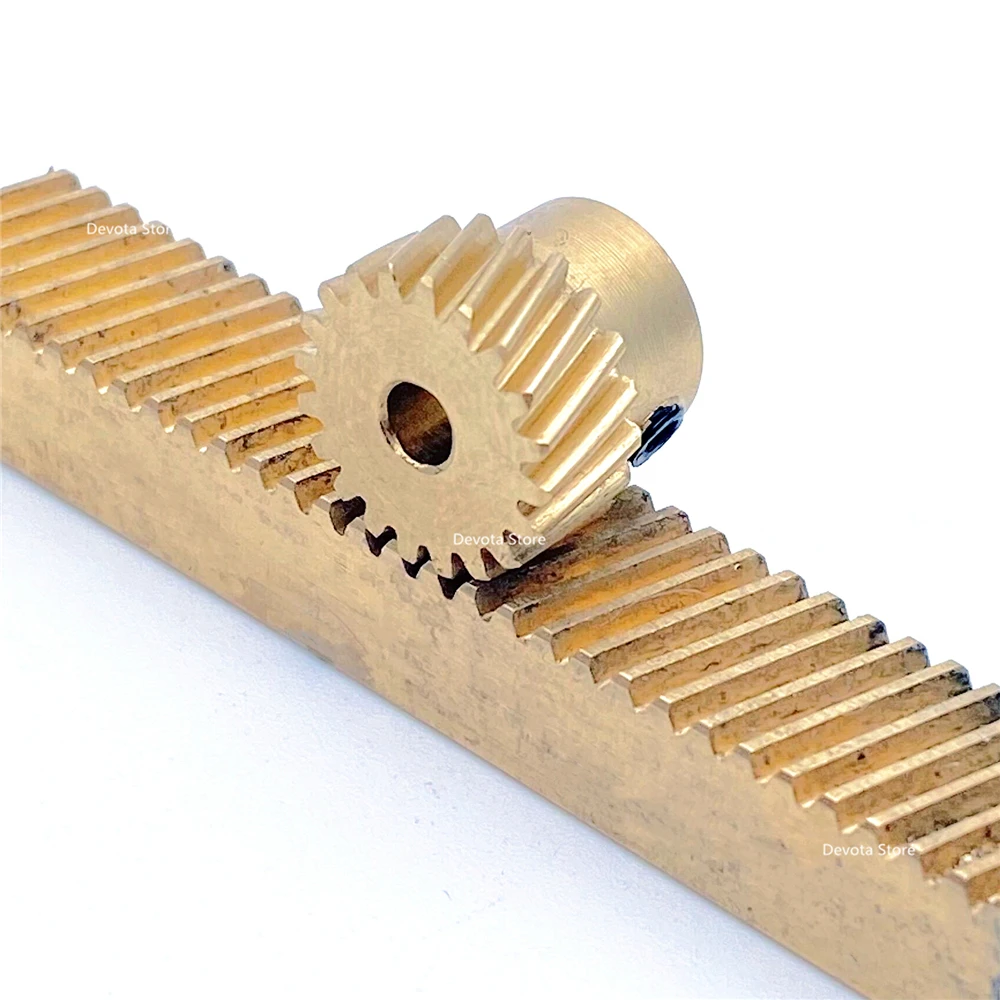

- Brass and Bronze

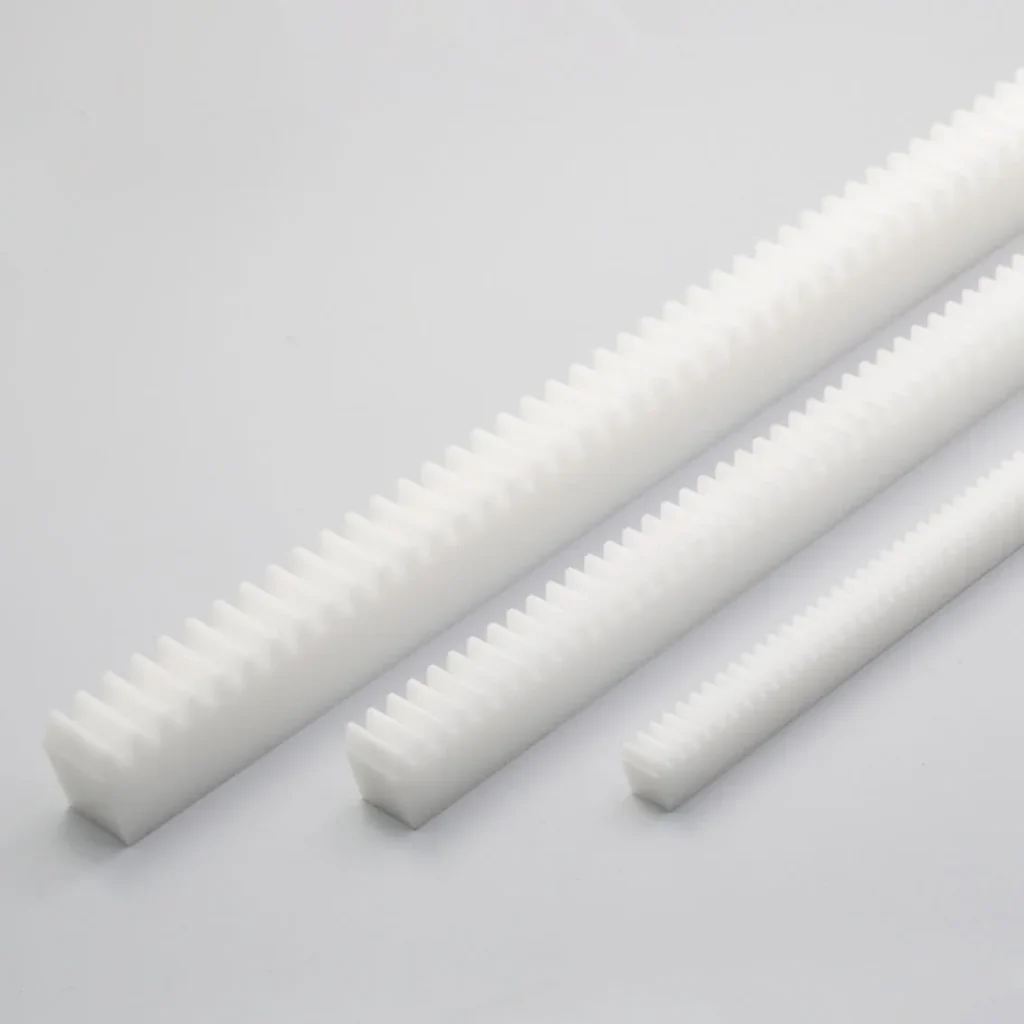

- Nylon

- Acetal

- Polycarbonate

- Peek

- Glass-Fiber Reinforced Plastics

Why Choose Us

Frequently ask question

Yes, we provide custom gear solutions based on your specific requirements, including Custom Gears, Plastic Gears, Internal Gears, and more.

Our prices are highly competitive, helping customers save up to 30% on costs while maintaining top-quality standards.

Our gears are widely used in automotive, machinery, electronics, medical devices, and various other industries, meeting specific customer needs.

We offer fast turnaround times, typically completing production and delivery within 7 days, ensuring your projects stay on schedule.

We have advanced manufacturing equipment and strict quality control processes. All products undergo precise testing to meet international standards.

Yes, we welcome customers from all over the world to visit our factory to see our manufacturing capabilities and quality control processes firsthand.

Yes, we provide reliable global shipping services to ensure timely delivery to your location, wherever you are.

We offer a wide range of gears, including Helical Gears, Bevel Gears, Worm Gears, Screw Gears, and more, catering to diverse application needs.

Our technical support team is available to assist you in selecting the best gear type and specifications based on your application requirements.

Yes, we can accommodate small batch custom production, meeting the needs of customers with different production scales while ensuring fast delivery.

Gear Rack Processing Process

Our company’s gear manufacturing process undergoes strict quality control and advanced technical support to ensure that each gear has high precision and high performance.

Applications

- Automotive

- Construction

- Electrical

- Electronics

- Heavy Equipment

- Industrial Machinery

- Marine

- Medical Devices

- Off-Highway

- Pneumatics

Services

-

Casting

-

Climb Hobbing

-

Conventional Hobbing

-

Forging

-

Grinding

-

Heat Treating

-

Honing

-

Flame Cutting

-

Lapping

-

Milling

-

Shaping

-

Shaving

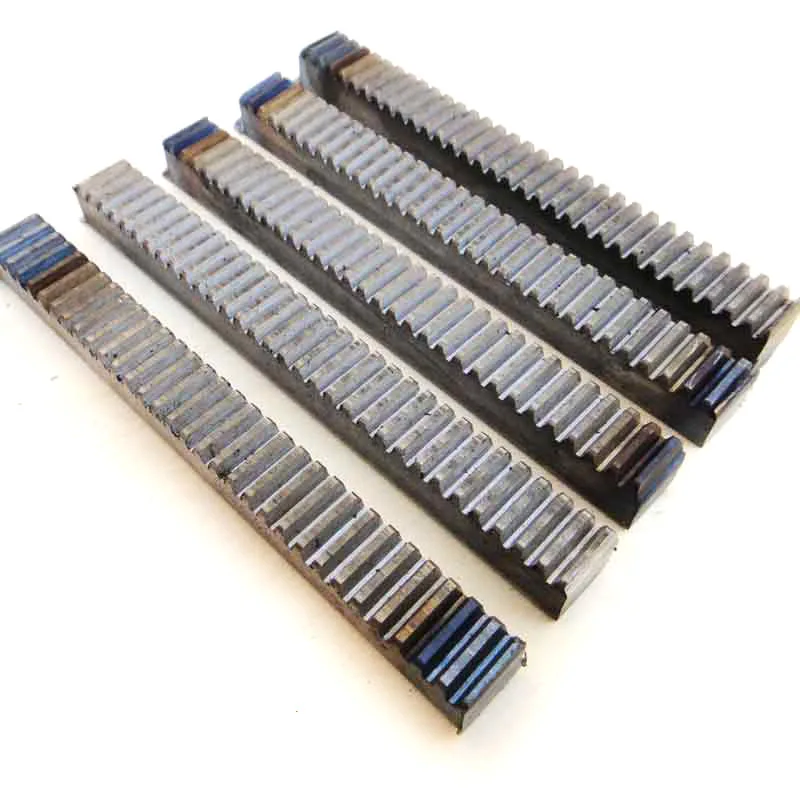

Finished Gear Rack Display

Gear Rack Manufacturing Service Experts

The types of gears we produce include: