Bevel Gears

- Bevel Gears Manufacturer Price, cost reduction of 30%

- Custom Bevel Gears according to drawings

- No MOQ

Our company is a leading bevel gear manufacturer, focusing on the production of various types of high-precision bevel gears. The types of bevel gears we produce include straight bevel gears, spiral bevel gears, miter gears, Zerol gears and anti-rebound gears, which are widely used in various industrial fields, such as automobiles, aerospace, mechanical transmission systems and high-precision instruments.

Types of our bevel gears:

Straight bevel gears: With a simple and durable structure, they are suitable for medium and low speed transmission devices, and are commonly found in mechanical equipment such as manual transmissions and differentials.

Spiral bevel gears: The tooth shape is spiral, with the advantages of smooth operation and low noise, and are widely used in high-speed transmission devices and precision machinery.

Miter gears: They have the characteristics of high stability and high efficiency in the transmission process, and are often used in heavy load and high torque transmission occasions.

Zerol gears: The tooth shape is close to straight teeth, but with a slight helix angle, combining the advantages of straight bevel gears and spiral bevel gears, and are suitable for a variety of precision mechanical equipment.

Anti-rebound gears: They have the function of preventing reverse motion, ensuring the safety and reliability of the transmission system, and are often used in industrial equipment with high precision requirements.

Applications of bevel gears:

Automotive industry: differentials, steering systems

Aerospace: aircraft power systems and landing gears

Mechanical transmission: power transmission of machine tools and heavy machinery

Energy equipment: transmission mechanism of wind turbines

Automation equipment: high-precision transmission systems in robots and automated production lines

Guide to custom bevel gears:

To ensure that your bevel gears fully meet specific needs, we provide customized services. Here are some key steps in the customization process:

Demand communication: First, customers need to provide information such as the specifications, materials, load requirements and use environment of the gears.

Design optimization: We will perform 3D design and modeling based on the data provided by customers to ensure that the structure and accuracy of the gears can meet the use requirements.

Material selection: According to the application environment of the gears, select appropriate materials, including carbon steel, alloy steel, stainless steel, etc., to ensure the strength and durability of the gears.

Processing technology: According to the complexity of the gears, we use CNC processing, forging, heat treatment and other processes to ensure that the gear accuracy meets international standards.

Quality inspection and delivery: Each gear undergoes strict quality inspection, including dimensional accuracy, tooth profile accuracy, hardness, etc., to ensure the quality of the final product. The production cycle is 7 days and the delivery is fast to all parts of the world.

We not only provide high-quality gear products, but also provide flexible customized solutions according to customer needs to help your business succeed.

Welcome to contact us to discuss more technical details and customization requirements of bevel gears.

- Jump to Section

- Workshop

- Material

- Advantages

- Faq

- Process

- Applications

- Finished product

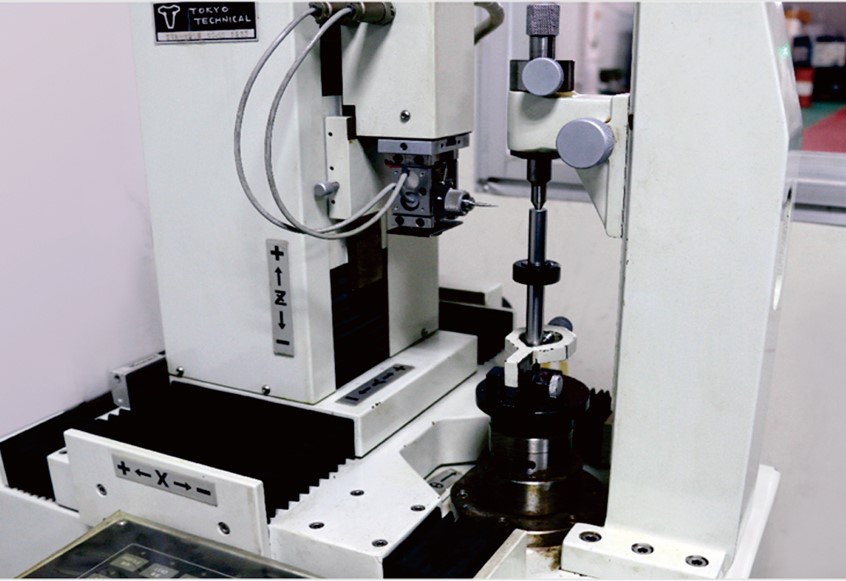

Bevel Gears Manufacturer Workshop

Bevel Gears Material Selection

- Carbon Steel

- Alloy Steel

- Stainless Steel

- Cast Iron

- Aluminum Alloys

- Brass and Bronze

- Nylon

- Acetal

- Polycarbonate

- Peek

- Glass-Fiber Reinforced Plastics

Why Choose Us

Frequently ask question

Yes, we provide custom gear solutions based on your specific requirements, including Custom Gears, Plastic Gears, Internal Gears, and more.

Our prices are highly competitive, helping customers save up to 30% on costs while maintaining top-quality standards.

Our gears are widely used in automotive, machinery, electronics, medical devices, and various other industries, meeting specific customer needs.

We offer fast turnaround times, typically completing production and delivery within 7 days, ensuring your projects stay on schedule.

We have advanced manufacturing equipment and strict quality control processes. All products undergo precise testing to meet international standards.

Yes, we welcome customers from all over the world to visit our factory to see our manufacturing capabilities and quality control processes firsthand.

Yes, we provide reliable global shipping services to ensure timely delivery to your location, wherever you are.

We offer a wide range of gears, including Helical Gears, Bevel Gears, Worm Gears, Screw Gears, and more, catering to diverse application needs.

Our technical support team is available to assist you in selecting the best gear type and specifications based on your application requirements.

Yes, we can accommodate small batch custom production, meeting the needs of customers with different production scales while ensuring fast delivery.

Bevel Gears Processing Process

Our company’s gear manufacturing process undergoes strict quality control and advanced technical support to ensure that each gear has high precision and high performance.

Applications

- Automotive

- Construction

- Electrical

- Electronics

- Heavy Equipment

- Industrial Machinery

- Marine

- Medical Devices

- Off-Highway

- Pneumatics

Services

-

Casting

-

Climb Hobbing

-

Conventional Hobbing

-

Forging

-

Grinding

-

Heat Treating

-

Honing

-

Flame Cutting

-

Lapping

-

Milling

-

Shaping

-

Shaving

Finished Bevel Gears Display

Bevel Gears Manufacturing Service Experts

The types of gears we produce include: