Home » Gauge

Gauge

The quality of the gauge determines the measurement accuracy. Choosing us ensures that each of your products is within the best tolerance range, helping you improve production quality.

Precision Gauge Products

We provide gauges to the highest standards, ensuring every inch fits your needs perfectly.

Our Gauge Manufacturing Capabilities

| Specification | Value |

|---|---|

| Diameter Tolerance | ±0.5 μm |

| Coaxiality | 0.2 μm |

| Roundness | 0.3 μm |

| Surface Roughness | Ra 0.04 μm |

| Straightness (600 mm) | Within 0.02 mm |

| Processing Range | 0.06 mm to 6000 mm |

The processing standards can be produced and inspected according to international industrial standards such as Japanese standard JIS, German standard DIN, American standard AISI, etc.

Equipped with high-precision CNC and measuring equipment to ensure that key indicators such as roundness, cylindricity and straightness meet the accuracy in demanding applications.

From raw material inspection, production process monitoring to finished product inspection, ensure the stability and reliability of each product in line with international standards.

Efficient production processes and flexible management systems quickly respond to customer needs and ensure on-time delivery to support customer production plans.

Request for a service today

Sed turpis tincidunt id aliquet risus feugiat in. Felis bibendum ut tristique et.

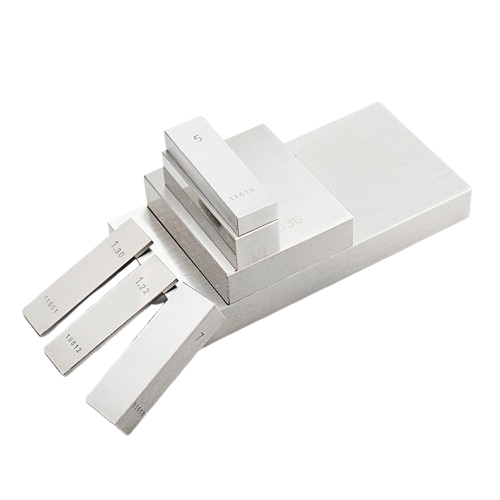

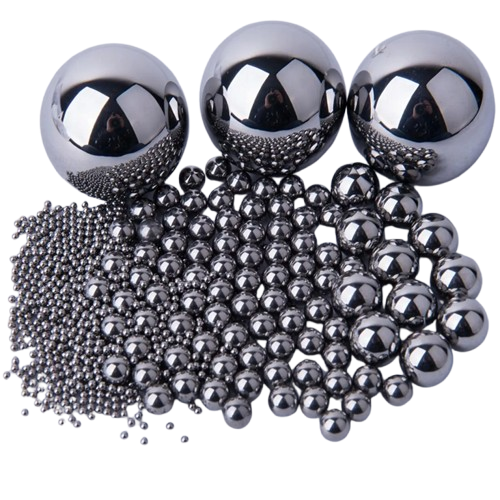

Finished Gear Display

Gauge Purchasing Guide

When purchasing gauges, understanding the types, accuracy requirements, and appropriate materials is essential. This guide will help you select the most suitable gauges to ensure precise measurements and operational efficiency.

1. Identify Application Needs

The type and specifications of a gauge directly impact its effectiveness in different applications. For example:

- Plug Gauges: Used for checking internal diameters, suitable for inspecting the inner diameter of components.

- Ring Gauges: Ideal for precise external diameter measurement, commonly used for shaft components.

- Thread Gauges: Specifically for threaded components, helping ensure thread specifications meet design requirements.

Before purchasing, clarify the primary application of the gauge to ensure it aligns well with your measurement needs.

2. Accuracy Requirements

Selecting a gauge with the appropriate level of accuracy is crucial. Shixinproto offers gauges with various precision levels to meet different measurement requirements:

- Standard Tolerances: Suitable for general industrial requirements, with a lower cost.

- High-Precision Gauges: Offering tolerances as tight as 0.0002 inches or better, ideal for high-demand applications.

Choose a gauge that meets the accuracy level you need to ensure reliable measurement results.

3. Choose the Right Material

The gauge material significantly affects its durability and suitability for specific environments. Shixinproto provides gauges in a range of materials to meet diverse needs:

- Hardened Steel Gauges: Highly wear-resistant, suitable for general manufacturing environments.

- Tungsten Carbide Gauges: Designed for high-wear environments, offering superior lifespan and stability over hardened steel.

- Chrome-Plated Gauges: Providing higher resistance to rust and corrosion, ideal for humid or corrosive work environments.

Selecting the appropriate material for your work environment ensures long-lasting gauge performance.

4. Ensure Compliance with Standards

Gauge standards vary across regions and industries, typically including:

- ANSI/ASME Standards: Applicable to North American industrial requirements.

- ISO Standards: Widely used internationally, suitable for global market needs.

Ensure your chosen gauges comply with specific industry or regional standards to guarantee consistency and accuracy in measurement results.

5. Customization and Additional Services

Shixinproto offers customization options for gauges to meet specific measurement needs. They also provide:

- Measurement Reports: Including precise dimensions and quality certification for each gauge.

- Recalibration Services: Ensuring long-term precision for gauges in ongoing use.

Selecting the appropriate service plan based on potential long-term needs can help extend gauge lifespan and maintain accuracy.

Summary

Purchasing gauges requires careful consideration to select the right type, accuracy level, material, and standard compliance. Choosing the right gauge from Shixinproto will help improve measurement efficiency and production quality.