Bronze has been a key part of human history for centuries. It’s used in everything from ancient sculptures to modern industrial tools. This guide will explore bronze’s types, properties, and uses in different industries.

If you’re into engineering, design, or just love bronze, this guide is for you. We’ll look at bronze alloys, their differences, and special uses. By the end, you’ll know how to pick the best bronze for your projects.

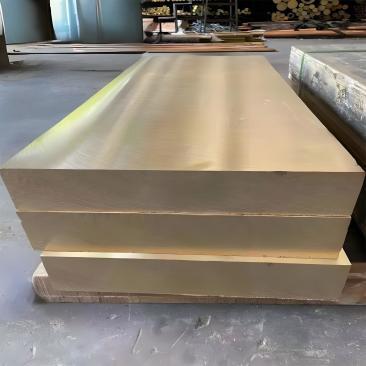

Bronze is known for its strength, durability, and resistance to corrosion. This guide will show you why it’s great for tough jobs and harsh places. You’ll see how bronze is used in car making, space tech, electrical work, and more.

Looking to get the most out of bronze or just curious? This guide is your go-to resource. It will help you understand and use bronze confidently and creatively.

Understanding the Basics of Bronze Alloys

Bronze, made mainly of copper and tin, has been around for centuries. It’s been key in tech, art, and industry. It shows how clever humans have always been.

What is Bronze and Why is it Important?

Bronze is a mix of copper and tin, used since the Bronze Age. It’s strong, lasts long, and doesn’t rust easily. This makes it perfect for many things, from old statues to today’s plane parts. Tin makes copper stronger, making bronze great for tough jobs.

Composition of Common Bronze Alloys

Bronze alloys have different mixes, but they usually have:

- Copper – The main part, making up 88-95%.

- Tin – Adds hardness and strength, 5-12% of the mix.

- Other elements – Small amounts of zinc, lead, or aluminum can be added to change its properties.

The exact mix of these parts decides what the bronze alloy can do. This makes it useful for many things in the bronze alloy basics and copper-tin alloy fields.

Types of Bronze Alloys and Their Applications

Bronze is a metal alloy known for its versatility and long history. It’s used in everything from ancient sculptures to today’s engineering projects. Let’s look at the different types of bronze and what makes them special.

Tin Bronze vs. Phosphor Bronze: Key Differences

Tin bronze, or copper-tin bronze, is well-liked for its strength and resistance to corrosion. Phosphor bronze, on the other hand, is a copper-tin-phosphorus alloy. It’s known for its high wear resistance and springiness, perfect for demanding mechanical tasks.

Applications of Aluminum Bronze

- Aluminum bronze is a strong and corrosion-resistant alloy. It’s often used in marine settings, like propellers and valves.

- It’s also great for bearings and bushings, and even for decorative items because of its golden color.

Leaded Bronze and Its Unique Uses

Leaded bronze is a copper-tin-lead alloy known for its easy machinability and self-lubricating properties. These traits make it ideal for precise machining, like gears and bearings.

“Leaded bronze is a go-to material for components that need to be precisely machined, as the lead in the alloy helps to improve the material’s cutting and shaping properties.”

Its self-lubricating qualities also make it great for parts in harsh environments. Here, traditional lubricants might not work as well.

How to Choose the Right Bronze Material for Your Project

Choosing the right bronze material is key to a successful project. When picking bronze alloys, several important factors need to be considered. This ensures the final product meets your specific needs.

Factors to Consider When Selecting Bronze Alloys

When selecting bronze alloys, consider the material properties needed for your project. These include:

- Strength and durability requirements

- Corrosion resistance in the intended environment

- Aesthetic considerations, like color and finish

- Cost and availability of the bronze alloy

By carefully evaluating thesebronze selection criteria, you can find the best material for yourproject requirements.

Common Mistakes to Avoid in Bronze Material Selection

To ensure a successful outcome, avoid common mistakes in bronze selection. Some common errors include:

- Overlooking the specific performance needs of the application

- Failing to account for the long-term environmental conditions

- Prioritizing cost over critical material properties

- Neglecting to consult with metal fabrication experts

By avoiding these mistakes, you can make an informed choice. This will help you select the optimal bronze alloy for your project.

| Bronze Alloy | Strength | Corrosion Resistance | Cost |

|---|---|---|---|

| Tin Bronze | High | Good | Moderate |

| Phosphor Bronze | Very High | Excellent | High |

| Aluminum Bronze | Moderate | Excellent | High |

| Leaded Bronze | Moderate | Good | Low |

The table above compares key material properties and cost for different bronze alloys. It helps you make an informed decision for your unique project requirements.

Properties of Bronze: Strength, Durability, and Corrosion Resistance

Bronze is a timeless alloy known for its outstanding properties. It’s perfect for many uses because of its bronze strength, durability, and corrosion resistance. It shines in high-stress situations.

Why Bronze is Ideal for High-Stress Applications

The strength of bronze alloys is key to its popularity. It’s made from copper and tin, making it strong against deformation and wear. This makes bronze great for parts that face heavy loads, vibrations, and impacts, like in cars, planes, and machines.

Bronze also stands out for its durability. It keeps its shape and works well for a long time. This makes it a top pick for places where things need to last a long time.

Corrosion Resistance of Bronze in Harsh Environments

Bronze is also known for its corrosion resistance. A protective layer on bronze keeps it safe from moisture, chemicals, and saltwater. This makes bronze perfect for tough places where other materials might fail.

“Bronze’s unique blend of strength, durability, and corrosion resistance makes it an invaluable material for a wide range of high-stress applications.”

In the car, plane, and machine worlds, bronze is a top choice. Its amazing properties ensure reliable and lasting solutions.

How Bronze Material is Used in Different Industries

Bronze is a strong and resistant alloy used in many industries. It’s found in cars, planes, and boats. This ancient metal is still key in today’s world.

Bronze in Automotive Manufacturing

In cars, bronze parts are tough and last long. They work well in engines and transmissions. Automotive bronze also helps with heat, making it great for cooling parts.

Bronze Components in Aerospace Applications

The aerospace world needs bronze for its strength and resistance to corrosion. Aerospace components like landing gear and brakes are made from it. This ensures safety and reliability in the skies.

Bronze in Electrical and Marine Applications

Bronze is also used in electrical and marine fields. It’s good for electrical parts because it conducts well and doesn’t corrode. In the sea, bronze resists saltwater and keeps parts clean. This makes it perfect for underwater use in marine applications.

| Industry | Bronze Applications | Key Benefits |

|---|---|---|

| Automotive | Bushings, bearings, transmission components | Durability, lubrication, wear resistance, thermal conductivity |

| Aerospace | Landing gear, brakes, engine components | Strength, corrosion resistance, thermal stability |

| Electrical | Connectors, switchgear, industrial components | Conductivity, corrosion resistance |

| Marine | Propellers, fittings, underwater components | Saltwater resistance, biofouling resistance |

Bronze is vital in many fields. It’s used in cars, planes, and boats. Its special qualities mean it lasts longer and works better in tough places.

Explore Shixinproto’s Custom Bronze Solutions

Shixinproto is a top manufacturer known for custom bronze solutions. They cater to various industries worldwide. Their team creates bronze alloys and parts that are both high-performing and cost-effective.

Shixinproto’s team works closely with clients to get their project needs. They use their deep knowledge and modern facilities to make custom bronze materials. These materials are designed to perform well in tough applications. They can make unique alloys, detailed castings, or special coatings to match your needs.

Shixinproto is known for its innovation and quality. Working with them means your custom bronze solutions will be top-notch. This ensures they perform well and give you an edge in the market.

FAQ

What is bronze and why is it an important material?

Bronze is a mix of copper and tin. It’s been used for centuries because it’s strong, durable, and doesn’t rust easily. Today, bronze is still key in many industries.

What are the common compositions of bronze alloys?

Bronze alloys usually have copper and tin. Sometimes, aluminum, phosphorus, or lead are added. These changes affect how bronze works and what it’s used for.

What are the key differences between tin bronze and phosphor bronze?

Tin bronze is the classic type, while phosphor bronze has phosphorus for more strength. Each type is better for different uses because of its unique mix.

How is aluminum bronze used in various industries?

Aluminum bronze is strong and doesn’t rust well. It’s used in cars, planes, and boats. Its special properties make it valuable in these fields.

What are the key factors to consider when selecting the right bronze material for a project?

When picking bronze, think about strength, how well it resists rust, cost, and what the project needs. Choosing wisely ensures the right bronze for the job.

What makes bronze an ideal material for high-stress applications?

Bronze is strong, lasts long, and doesn’t wear out easily. It’s perfect for jobs that need to handle a lot of stress. Its durability makes it popular in many fields.

How does the corrosion resistance of bronze benefit its performance in harsh environments?

Bronze doesn’t rust well, even in tough places like the sea or factories. This means it stays strong and works well, even when exposed to harsh conditions.

In what ways is bronze utilized in the automotive and aerospace industries?

Bronze is used in cars and planes for its strength and resistance to rust. In cars, it’s in parts like bearings and valves. In planes, it’s in engine parts and landing gear.

How does Shixinproto’s expertise in custom bronze solutions benefit clients?

Shixinproto creates special bronze solutions for many industries. They work with clients to make bronze alloys and parts that fit each project’s needs. This ensures the best performance and value.