In the world of metalworking, brass, bronze, and copper are key players. They have shaped tools, technologies, and art for centuries. Knowing their unique qualities is essential for choosing the right metal for your project.

Brass is a mix of copper and zinc, known for its strength and golden color. Bronze combines copper and tin, offering great strength and beauty. Copper, a pure metal, is top-notch for conducting heat and electricity, vital in electronics.

We’ll explore the makeup, main features, and uses of these metals. This will help you pick the best material for your needs.

What are Brass, Bronze, and Copper?

Brass, bronze, and copper are metals used for centuries in many ways. Knowing what makes each unique helps pick the best for your project.

Understanding the Composition of Brass

Brass is mostly copper and zinc. It usually has about 67% copper and 33% zinc. This mix gives brass its yellowish-gold look. It’s strong, resistant to corrosion, and easy to work with, making it popular.

Key Features of Bronze Alloys

Bronze is made from copper and tin. But today, it can also have other metals like aluminum or silicon. It’s known for its reddish-brown color and is strong and resistant to corrosion. Bronze’s properties vary, making it good for many uses.

The Versatility of Pure Copper

Pure copper is a single metal known for its great electrical and thermal conductivity. It’s also very flexible and can be shaped easily. Its ability to resist corrosion and fight off germs makes it valuable in many fields, from wiring to plumbing.

| Metal | Composition | Key Features |

|---|---|---|

| Brass | Copper (67%) and Zinc (33%) | Corrosion resistance, strength, and machinability |

| Bronze | Copper and Tin, with possible additions of other metals | Durability, strength, and corrosion resistance |

| Copper | Pure Copper | Excellent electrical and thermal conductivity, malleability, ductility, and corrosion resistance |

Differences Between Brass, Bronze, and Copper

Brass, bronze, and pure copper are all unique metals. Each has its own special qualities. Knowing these differences can help you choose the best metal for your project.

Visual Differences in Appearance

The visual appearance of these metals is quite different. Brass has a warm, golden-yellow color. Bronze is reddish-brown. Pure copper shines with a reddish-orange metallic luster. These colors come from the different mixtures of metals in each.

Comparing Strength and Durability

The strength and durability of these metals vary. Bronze is the strongest, with a higher tensile strength. Brass is more malleable and easier to work with, great for detailed designs. Pure copper is not as strong as bronze but is still durable and flexible.

Corrosion Resistance of Brass, Bronze, and Copper

The corrosion resistance of these metals also differs. Brass has a moderate resistance to corrosion. Bronze, with more copper, is very resistant to corrosion, especially in saltwater. Pure copper, being non-ferrous, is also very resistant to corrosion, making it ideal for electrical and plumbing uses.

| Characteristic | Brass | Bronze | Copper |

|---|---|---|---|

| Appearance | Warm, golden-yellow | Reddish-brown | Reddish-orange metallic luster |

| Strength and Durability | Malleable and easy to machine | Highest tensile strength | Durable and flexible |

| Corrosion Resistance | Moderate resistance | Highly resistant, especially in marine environments | Highly resistant, non-ferrous metal |

Applications of Brass, Bronze, and Copper

Brass, bronze, and copper are versatile metals used in many industries. They have unique properties that make them valuable in everyday and specialized uses.

Brass in Plumbing and Musical Instruments

Brass is a mix of copper and zinc. It’s often used in plumbing, like faucets and valves, because it doesn’t corrode easily. It also looks good.

Brass is also in musical instruments, like trumpets and saxophones. It’s valued for its sound quality and durability.

Bronze in Marine and Industrial Applications

Bronze is made of copper and tin. It’s strong and doesn’t corrode, making it perfect for marine and industrial uses. It’s used in propellers and machinery that face harsh conditions.

Its ability to resist salt water and weather makes it reliable for outdoor and marine gear.

Copper in Electrical and Thermal Applications

Copper is a pure metal known for its electrical and thermal conductivity. It’s crucial in the electrical field, used in wiring and panels. It’s also in heat exchangers and radiators for efficient heat transfer.

Brass, bronze, and copper are essential in many fields. They’re in our homes and in the instruments that bring us joy. These metals are vital in shaping our world.

Choosing the Right Metal for Your Project

Choosing the right metal for your project is key. Brass, bronze, and copper each have their own benefits. It’s important to think about what you need before deciding.

When to Use Brass, Bronze, or Copper Based on Requirements

Brass is great for projects needing easy machining, resistance to corrosion, and a golden look. It’s often used in plumbing, musical instruments, and decorative items. Bronze is strong and durable, making it perfect for marine and industrial uses like statues and bearings.

Copper is top for electrical and thermal conductivity. It’s used in wiring, heat exchangers, and electronics. Its antimicrobial properties also make it good for healthcare and food equipment.

Factors to Consider: Cost, Strength, and Corrosion Resistance

When picking a metal, consider cost, strength, and how it handles corrosion. Brass is cheaper than bronze, but copper is the priciest. Bronze is the strongest, followed by brass and then copper. Brass and copper are best at resisting corrosion, but bronze might need more care in some places.

| Metal | Cost | Strength | Corrosion Resistance |

|---|---|---|---|

| Brass | Moderate | Good | Excellent |

| Bronze | Higher | Excellent | Good |

| Copper | Highest | Moderate | Excellent |

Think about these factors and what your project needs. This will help you choose the best metal for your project, whether it’s brass, bronze, or copper.

Why Choose Shixinproto for Your Brass, Bronze, and Copper Machining Needs?

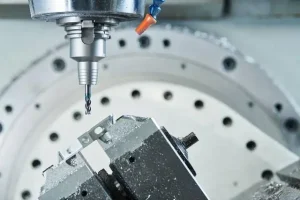

Shixinproto is a top choice for precision metal machining. They have years of experience with brass, bronze, and copper. Their advanced facilities use the latest technology to ensure high-quality parts.

Shixinproto is known for its commitment to excellence. They work closely with clients to understand their needs. Whether it’s brass fittings, bronze components, or copper heat sinks, they can make it happen.

The team at Shixinproto is all about precision and detail. They provide outstanding customer service from start to finish. Choosing Shixinproto means your metal machining needs are in good hands.

FAQ

What is the difference between brass, bronze, and copper?

Brass is a mix of copper and zinc. Bronze is made of copper and tin. Copper is pure copper. Each has unique qualities for different uses.

What are the key features of brass, bronze, and copper?

Brass is tough, resists corrosion, and is easy to work with. Bronze is strong, casts well, and lasts long outdoors. Copper is great at conducting heat and electricity, and is soft and flexible.

How do the visual appearances of brass, bronze, and copper differ?

Brass looks golden-yellow. Bronze has a reddish-brown color. Copper has a reddish-orange look. Their looks come from their makeup and how they’re mixed.

What are the common applications of brass, bronze, and copper?

Brass is used in plumbing, music, and decorations. Bronze is found in the sea, sculptures, and machines. Copper is in wiring, heat exchangers, and many products.

How do I choose the right metal for my project?

Pick brass, bronze, or copper based on what you need. Think about cost, strength, how it holds up, and what you’re making. Your budget, what you need it to do, and where it will be help decide.

Why should I choose Shixinproto for my brass, bronze, and copper machining needs?

Shixinproto is a top name in machining these metals. We make high-quality parts and follow your exact needs. We focus on making you happy and use new ways to make things.