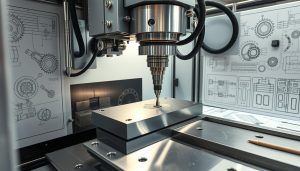

In today’s fast-changing world, precision CNC machining is key for making top-notch, custom metal parts. Metal fabrication services that use CNC technology are unmatched in accuracy, efficiency, and cost. They are a must-have for companies in many fields. Whether you need complex parts for aerospace, cars, or industry, the best CNC machining services have what you need.

CNC machining combines computer-aided design (CAD) with advanced machinery. It can work with many materials like aluminum, stainless steel, and titanium. This technology is changing what’s possible in modern manufacturing. With CNC machining, you can create your metal projects with the highest quality and speed.

Understanding CNC Machining for Metal Fabrication

CNC technology, or Computer Numerical Control, has changed metal fabrication. It makes making complex metal parts easy and fast. Knowing how CNC machining works helps us use it better for metal projects.

What is CNC Machining and How Does It Work?

CNC machining uses computers to control tools that shape metal. The CNC machine follows a set of instructions, called G-code. This makes the process accurate and cuts down on mistakes.

Advantages of CNC Machining for Metal Projects

- Increased Precision: CNC machines can be very precise, making parts fit perfectly.

- Enhanced Repeatability: CNC machining makes it easy to make the same part over and over. This is great for making lots of parts at once.

- Ability to Produce Complex Geometries: CNC technology can make parts with complex shapes. This is hard or impossible to do by hand.

- Improved Efficiency and Reduced Lead Times: CNC machining is fast and accurate. This makes metal fabrication quicker and more productive.

CNC technology helps metal fabrication projects a lot. It makes parts more precise, efficient, and complex. This is why CNC machining is so important for businesses that want to be competitive.

Top CNC Machining Services for Metal Fabrication

Finding a good CNC machining service for custom metal work is key. These companies offer top-notch engineering and craftsmanship. They help make your metal projects real. Let’s look at some top CNC machining providers for custom metal parts.

Leading CNC Companies for Custom Metal Parts

ABC Manufacturing is a top name in CNC machining. They have the latest tools and skilled workers. They handle everything from small prototypes to big production runs.

XYZ Precision is known for precise CNC machining. They use the latest tech for tight tolerances and smooth finishes. They’re great for complex metal parts.

Metalworks Inc. offers a wide range of CNC services. They do CNC milling, turning, and EDM. They also test their work to ensure quality.

Factors to Consider When Choosing a CNC Machining Service

When picking a CNC machining service, consider a few things:

- Experience and Expertise: Choose a service with a good track record in custom metal work. Make sure they know how to handle your project.

- Equipment Capabilities: Check the CNC machines and tech they use. This affects the parts’ precision, complexity, and size.

- Quality Assurance: Look for services with strong quality control. They should have inspection processes and certifications to ensure your parts are top-notch.

| Company | Specialty | Key Capabilities |

|---|---|---|

| ABC Manufacturing | Custom Metal Fabrication | CNC milling, turning, and welding |

| XYZ Precision | High-Precision CNC Machining | CNC milling, turning, and EDM |

| Metalworks Inc. | Comprehensive CNC Services | CNC milling, turning, EDM, and quality assurance |

By looking at these factors, you can find the best CNC machining service. They’ll help make your metal projects come to life with great quality and precision.

CNC Machining for High-Precision Metal Fabrication

CNC machining is a game-changer in making precise metal parts. It’s known for its accuracy and speed. This makes it a top pick for many industries, like aerospace and medical.

How CNC Machining Enhances Precision and Efficiency

CNC machining is all about computer control. This means CNC machines can do complex tasks with great accuracy. Such precision is key for parts that need to fit together perfectly.

Also, CNC machining makes things faster by automating the process. CNC machines work non-stop, cutting down on human mistakes. This leads to more work done and saved costs, helping all kinds of businesses.

Types of CNC Machines Used in Metal Fabrication

In metal fabrication, different CNC machines are used for various tasks. Each has its own strengths and uses:

- CNC milling machines – These can cut and shape metal into many forms. They’re great for making complex parts.

- CNC turning machines – Known as CNC lathes, they’re for making round parts like shafts.

- Multi-axis CNC machines – These can do many things, like milling, turning, and even 3D printing. They’re very versatile for high-precision manufacturing.

Using these CNC machines, makers can create metal parts that meet strict standards. This ensures top quality and performance.

CNC Machining Cost and Pricing Models

Understanding the cost of CNC machining for metal fabrication is key. Prices change based on material, project complexity, and work scope. Let’s look at CNC machining costs and how they’re affected by these factors.

How Much Does CNC Machining for Metal Fabrication Cost?

CNC machining costs vary a lot. Simple parts might cost a few hundred dollars, while complex designs can reach thousands. The price depends on the metal type, part size, quantity, and customization needs. More complex designs and rare materials increase the cost.

Pricing Breakdown Based on Material and Complexity

Here’s a detailed look at pricing based on material and complexity:

| Material | Complexity | Estimated Cost Range |

|---|---|---|

| Aluminum | Simple | $50 – $500 per part |

| Aluminum | Complex | $500 – $2,000 per part |

| Stainless Steel | Simple | $100 – $1,000 per part |

| Stainless Steel | Complex | $1,000 – $5,000 per part |

| Titanium | Simple | $500 – $2,000 per part |

| Titanium | Complex | $2,000 – $10,000 per part |

Keep in mind, these are just estimates. Actual CNC machining costs can differ based on your metal fabrication project and cost-effective manufacturing methods.

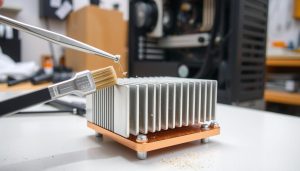

Why Choose Shixinproto for Your CNC Machining Needs

Shixinproto is a top choice for precision metal fabrication. They are known for their excellence and skilled team. They offer top-notch CNC machining services for any project.

Expert CNC Services for Metal Fabrication Projects

Shixinproto uses the latest CNC machines for high-quality results. They handle everything from custom parts to complex metal components. Their Shixinproto CNC services are unmatched, making them the best for professional metal fabrication.

The Shixinproto team has years of experience. They use their industry-leading machining to ensure precision and reliability. Whether it’s for aerospace, automotive, or any other field, Shixinproto will meet your needs and bring your ideas to life.

FAQ

CNC machining is a way to make parts using computers and machines. It cuts and shapes materials like metals and plastics. A computer program tells the machines what to do, making parts very accurate and the same every time.

CNC machining is great for metal projects because it’s precise and fast. It can make complex shapes that manual methods can’t. This makes it better for detailed work.

Look for a CNC service with experience and the right tools. Check their quality control and if they meet your project needs. Good customer service and quick turnaround are important too.

CNC uses advanced tech for precise and efficient metal work. It has tools that change automatically and measures parts as it goes. This makes the process reliable and can handle complex parts.

CNC machining costs depend on the part, material, and how many you need. It’s often cheaper than manual methods. Prices are usually by the hour or per part, with discounts for more orders.

Shixinproto is a top choice for CNC machining. We have the latest tools and skilled staff. Our focus on quality and customer satisfaction makes us the best partner for your projects.