In today’s manufacturing world, finding the perfect surface quality is key. Bead blast finishing is a new method that changes metal surfaces. It’s used in many fields, from aerospace to cars, to make them look and work better.

Bead blasting uses air to shoot tiny beads at metal. This makes the surface smooth and even. It looks great and also lasts longer and resists rust better.

What is Bead Blasting?

Bead blasting, also known as abrasive blasting, is a surface preparation method. It uses small, round media to improve the look and function of metal surfaces. The process blasts a stream of selected particles, like glass or plastic beads, at high speed. This removes dirt, smooths out rough spots, and gives a uniform finish.

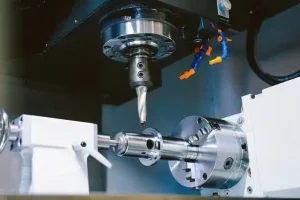

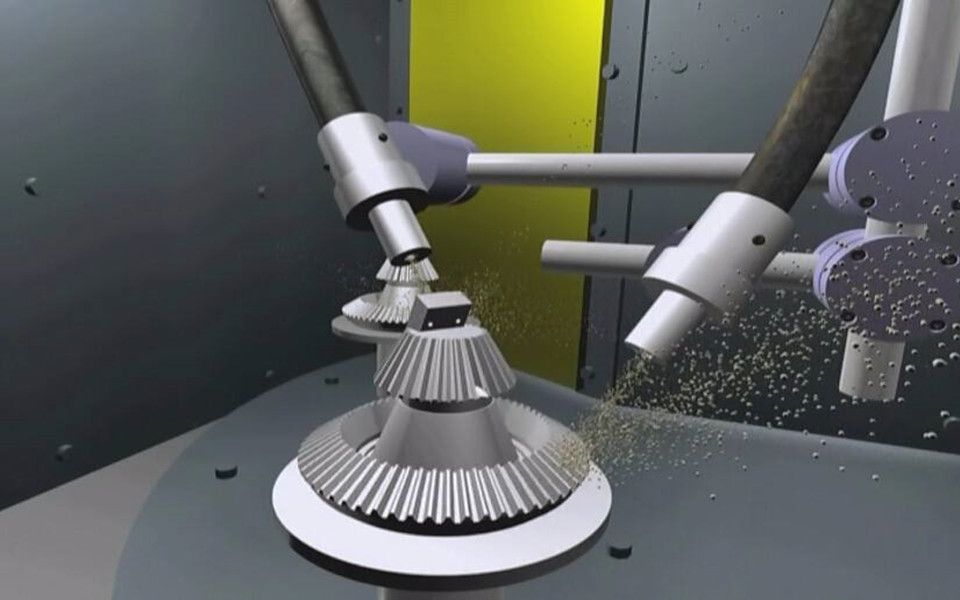

The Bead Blasting Process: How It Works

The process starts with picking the right media for the job. The chosen media goes into a blasting machine. There, it’s sped up by air or a spinning force and hits the surface. This gentle erosion removes unwanted coatings and rust, keeping the metal underneath safe.

The Different Types of Media Used in Bead Blasting

- Glass Beads: Perfect for delicate surfaces, glass beads offer a smooth, matte finish and even blast.

- Ceramic Beads: More durable and aggressive, ceramic beads are great for tough jobs like removing stubborn coatings.

- Plastic Beads: A softer option, plastic beads are used for sensitive materials or where a gentle touch is needed.

Bead Blasting vs Sandblasting: Key Differences

Bead blasting and sandblasting are both abrasive techniques, but they’re not the same. Sandblasting uses sharp sand particles, making a rougher surface. Bead blasting, with its round media, gives a smoother finish. Plus, bead blasting is better for the environment because it produces less dust.

Benefits of Bead Blast Finishing

Bead blast finishing is a versatile metal treatment process. It offers many benefits for industrial applications. It can enhance surface quality and improve corrosion resistance, making metal parts look and last better.

Improving Surface Finish and Texture

Bead blast finishing makes metal surfaces smooth and even. It uses small, abrasive beads to remove imperfections and flatten high spots. This is especially useful in industries like aerospace, where a precise finish is crucial.

Corrosion Resistance and Durability

This process also boosts the long-term performance of metal components. It creates a dense surface that resists corrosion and wear. This makes the parts last longer, making bead blasting great for harsh environments.

Enhanced Aesthetic Appeal of Finished Parts

Bead blast finishing also improves the look of metal products. It gives a matte, uniform finish that looks sleek and modern. This is especially valuable in industries like jewelry and decorative arts, where looks matter a lot.

| Benefit | Description |

|---|---|

| Improved Surface Finish | Bead blasting creates a smooth, consistent texture by removing imperfections and flattening high spots. |

| Increased Corrosion Resistance | The compacted surface created by bead blasting is less susceptible to corrosion, enhancing the durability of the treated parts. |

| Enhanced Aesthetic Appeal | Bead blast finishing can give metal components a sleek, modern look, making it a popular choice for decorative and high-end applications. |

Applications of Bead Blasting in Various Industries

Bead blast finishing is a versatile technique used in many industries. It’s used in aerospace, automotive, and decorative metalwork. This method is key for improving metal component quality and looks across different sectors.

Bead Blasting in Aerospace Manufacturing

In aerospace, bead blasting is vital for making critical parts. It makes surfaces even and durable, fighting corrosion. This is crucial for parts in aircraft and spacecraft.

It also ensures parts fit perfectly, meeting aerospace standards.

Automotive and Industrial Uses of Bead Blast Finishing

The automotive world benefits a lot from bead blast finishing. It’s used to make metal parts look better, from trim to functional parts. Bead blasting can give different finishes, from matte to textured.

This lets manufacturers meet their design goals for cars.

Bead blasting is also used in many industrial areas. It prepares metal for painting, plating, or anodizing. This treatment boosts adhesion and quality, making products better.

Jewelry and Decorative Applications of Bead Blasting

Bead blasting is also popular in jewelry and decorative metalwork. It creates unique textures on metals, making jewelry stand out. Jewelers and metalworkers use it for matte finishes and other designs.

When to Use Bead Blasting Over Other Finishing Techniques

Choosing the right metal finishing technique can be tough. You have many options like surface treatment comparison, metal finishing techniques, and bead blast finishing. We’ll look at when bead blasting is better than other methods like anodizing, sandblasting, and polishing.

Bead Blasting vs. Anodizing: Which Is Right for Your Project?

Bead blasting and anodizing are both used for metal finishing. Bead blasting makes the surface look better and is cheaper. Anodizing gives better protection against corrosion and looks more decorative.

If you want a smooth, matte look, bead blasting is good. But for better protection and a fancy look, anodizing is better.

Sandblasting or Polishing: Deciding on the Best Finish

When comparing bead blast finishing to sandblasting or polishing, there are differences. Sandblasting makes a rougher surface, while polishing makes it smooth and shiny. Bead blasting gives a matte finish that’s not too rough or too smooth.

For a specific look or function, like better grip or a unique look, bead blasting is great.

The choice between bead blasting and other techniques depends on your project’s needs. Consider cost, durability, and look. Knowing each method’s strengths and weaknesses helps you choose the best one for your project.

Why Choose Shixinproto for Your Bead Blast Finishing Services?

Shixinproto is the top choice for bead blasting, metal surface treatment, and industrial finishing services. We have the latest equipment and a skilled team. This makes us known for our excellent work across many industries.

We know how crucial a perfect finish is for your metal parts. Our bead blasting techniques improve their look, resistance to corrosion, and strength. This ensures your parts are of the highest quality. We work on everything from aerospace to cars, doing each job with great care.

Our clients trust us because we always put their needs first. We communicate well, work around your schedule, and deliver on time. With Shixinproto, you can count on your metal parts getting the best care. They will always look their best.

FAQ

What is bead blasting?

Bead blasting is a way to clean and smooth surfaces using small beads. It’s often used on metal. The beads are shot at high speed to create a uniform finish.

How does the bead blasting process work?

Bead blasting uses a blast cabinet. Here, metal parts are cleaned with beads shot by air or a wheel. This removes dirt and smooths the surface, leaving a matte finish.

What are the different types of media used in bead blasting?

Bead blasting uses glass, ceramic, or plastic beads. Each type is chosen based on the project’s needs. Glass beads are cheap and smooth, ceramic beads are hard, and plastic beads are gentle.

How does bead blasting differ from sandblasting?

Bead blasting uses round beads, while sandblasting uses sharp particles. Bead blasting gives a smoother finish. Sandblasting makes a more textured surface.

What are the benefits of bead blast finishing?

Bead blast finishing improves the look and feel of surfaces. It makes them smoother and more even. It also makes them last longer and look better.

In what industries is bead blasting used?

Bead blasting is used in many fields. It’s in aerospace, cars, jewelry, and medical devices. It’s for looks and to make parts last longer.

When should I choose bead blasting over other finishing techniques?

Choose bead blasting for a smooth, matte finish. It’s good for looks and durability. It’s also cheaper than some other methods.

Why should I choose Shixinproto for my bead blast finishing needs?

Shixinproto is a top choice for bead blasting. They have the best equipment and skilled workers. They focus on quality and care for your parts.