In the world of car making, precision is key. The car industry keeps changing, and CNC machining plays a big role. It makes car parts with unmatched accuracy, speed, and cost savings.

CNC machining is now the top choice for making car parts. It helps car makers work faster and better. This technology makes sure every part is top quality, which is crucial in today’s fast car market.

We will look into how CNC machining helps make cars better. We’ll see how it makes high-performance vehicles and parts possible.

What is Automotive CNC Machining?

Automotive CNC machining is a precise and automated way to make car parts. It uses special CNC machines to create many car parts with great accuracy and speed.

The Role of CNC Machines in Modern Automotive Manufacturing

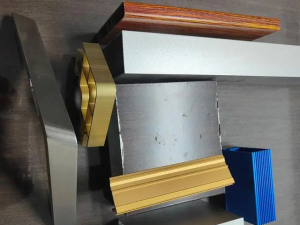

CNC machines have changed the car industry a lot. They make complex parts with amazing precision. These machines can cut, shape, and drill different materials like metal and plastic. They help make parts that meet high quality standards in cars.

Types of CNC Machines Used in the Automotive Industry

- CNC Lathes – Specialized for turning and shaping cylindrical parts, such as engine crankshafts, camshafts, and transmission components.

- CNC Milling Machines – Versatile machines that can create complex 3D shapes, ideal for manufacturing components like engine blocks, cylinder heads, and suspension parts.

- Multi-Axis Machining Centers – Advanced CNC machines capable of performing multiple operations simultaneously, allowing for the production of highly intricate automotive parts with unparalleled precision.

These CNC machines are key to making car parts in the auto industry. They help make high-quality parts with unmatched speed and consistency.

Key Applications of CNC Machining in Automotive Manufacturing

Computer Numerical Control (CNC) machining is key in modern car making. It’s used for engine parts, suspension, and brakes. CNC tech is vital for making many important car systems. Let’s look at how CNC machining helps in car making.

CNC Machining for Engine Components

CNC is used a lot for engine parts like engine block machining and cylinder heads. It makes sure these parts are made with high precision. This boosts engine performance and makes it last longer.

CNC Machining for Suspension and Brake Parts

CNC is also crucial for car suspension and brakes. Brake rotors and suspension arms get better with CNC’s exact control. This means cars can handle better and are safer.

CNC Machining for Transmission and Exhaust Components

CNC is used for more than just engine and chassis parts. It’s also for transmission and exhaust parts. CNC’s ability to handle complex shapes and tight tolerances is essential for these parts.

| Application | CNC Machined Components |

|---|---|

| Engine | Engine block, Cylinder heads |

| Suspension and Brakes | Brake rotors, Suspension arms |

| Transmission and Exhaust | Gears, Shafts, Manifolds |

CNC machining’s versatility and precision are vital in car making. It helps make many important car parts efficiently and with high quality.

Advantages of CNC Machining in Automotive Production

The automotive industry is changing fast, and CNC machining is at the forefront. This technology brings many benefits, like better automotive quality control and cheaper mass production.

Precision and Accuracy in Manufacturing Automotive Parts

CNC machining is great for making car parts with high precision. It uses computers and special tools to create parts that fit perfectly. This means cars work better and last longer.

Cost-Effective High-Volume Production

CNC machining is also good for making lots of parts quickly and cheaply. It automates the process, saving on labor costs. This helps car makers make more parts without spending too much.

Flexibility and Speed in Producing Complex Automotive Components

CNC machining is flexible and fast, perfect for the fast-changing car market. It can quickly make complex parts, meeting new demands fast. This is key for car makers to stay ahead.

Using CNC machining, car makers can improve quality, performance, and speed. This means better cars for everyone.

How CNC Machining Enhances Automotive Design and Prototyping

In the fast world of automotive engineering, quick prototyping and design changes are key. CNC machining has changed the game, making design and development faster and better.

Rapid Prototyping in Automotive Engineering

CNC machining makes quick, precise prototypes. This lets designers and engineers test their ideas in real life. It speeds up the design iteration process, making automotive prototypes better faster.

By combining CNC machining with CAD/CAM integration, moving from digital to physical models is smooth. This makes the concept-to-production process more efficient.

How CNC Machining Improves Design Flexibility

CNC machining lets designers try new things. It can make complex shapes and details, opening up new ideas. This boosts design flexibility and leads to unique, eye-catching car designs.

“CNC machining has become an indispensable tool in the automotive design and prototyping process, enabling us to rapidly translate our ideas into tangible reality.”

– John Doe, Lead Automotive Designer

Challenges and Solutions in Automotive CNC Machining

The automotive industry is always looking to improve design and performance. CNC machining faces unique challenges in this pursuit. It must work with advanced materials and create parts with complex shapes. Innovative solutions are needed to keep up with these demands.

Overcoming Material Constraints in CNC Machining

High-performance alloys and advanced materials are becoming more common in cars. These materials, like titanium and exotic aluminum, are hard to machine. To overcome this, specialized tools and knowledge of the material’s behavior are essential.

Addressing the Challenges of Producing Complex Automotive Parts

Car designs are getting more complex, with parts needing tight tolerances. CNC machining these parts is a big challenge. It requires advanced programming and strategies. Solutions like multi-axis machining and advanced materials help meet these demands.

By improving processes and using new technologies, CNC machining stays crucial. It helps create complex geometries and precision tolerances that advance the industry.

Explore Shixinproto’s CNC Machining Services for Automotive Industry

Shixinproto is a top name in precision manufacturing. They offer CNC machining services made just for the auto industry. Their advanced tech and skilled team make them a go-to for car makers looking for top-notch parts.

Shixinproto can make everything from engine parts to brakes and suspension. Their CNC machines make parts with perfect accuracy and quality. They focus on quality at every step, meeting the auto market’s high standards.

Car companies looking for new ways to make parts can count on Shixinproto. They specialize in custom CNC machining for cars. This lets designers and engineers quickly test and make their ideas real. Shixinproto uses CNC tech to help car makers stay ahead in a fast-changing world.

FAQ

What is Automotive CNC Machining?

Automotive CNC machining uses computer numerical control (CNC) technology. It makes various car parts with high accuracy and speed. CNC machines are programmed to cut, shape, and make parts with precision.

What are the Key Applications of CNC Machining in Automotive Manufacturing?

CNC machining is used for many car parts. This includes engine blocks, cylinder heads, and brake rotors. It also makes parts for the transmission and exhaust system. CNC technology helps make these complex parts accurately.

What are the Advantages of CNC Machining in Automotive Production?

CNC machining offers many benefits. It ensures parts are made with high precision and accuracy. It also makes high-volume production cost-effective and faster. These advantages improve vehicle quality and performance.

How does CNC Machining Enhance Automotive Design and Prototyping?

CNC machining is vital for car design and prototyping. It allows for quick prototyping and design changes. This helps engineers test and refine their ideas faster, leading to better car designs.

What are the Challenges and Solutions in Automotive CNC Machining?

Challenges include working with advanced materials and achieving tight tolerances. Complex geometries are also a challenge. To solve these, advanced tooling and process optimization are used. These solutions ensure high-quality car parts are made.