The car chassis is the heart of any vehicle. It gives the car its structure and support. This guide will cover the car chassis’s role, its types, materials, and design impact on performance and safety.

We’ll look at the monocoque and ladder frame chassis types. You’ll learn how they affect a car’s handling and stability. We’ll also talk about new materials like aluminum and composites and their role in car engineering.

If you love cars, work in the industry, or just want to know more about your vehicle, this guide is for you. We’ll explore the design and engineering of the car chassis. You’ll see how it’s evolving to meet today’s transportation needs.

What is a Car Chassis?

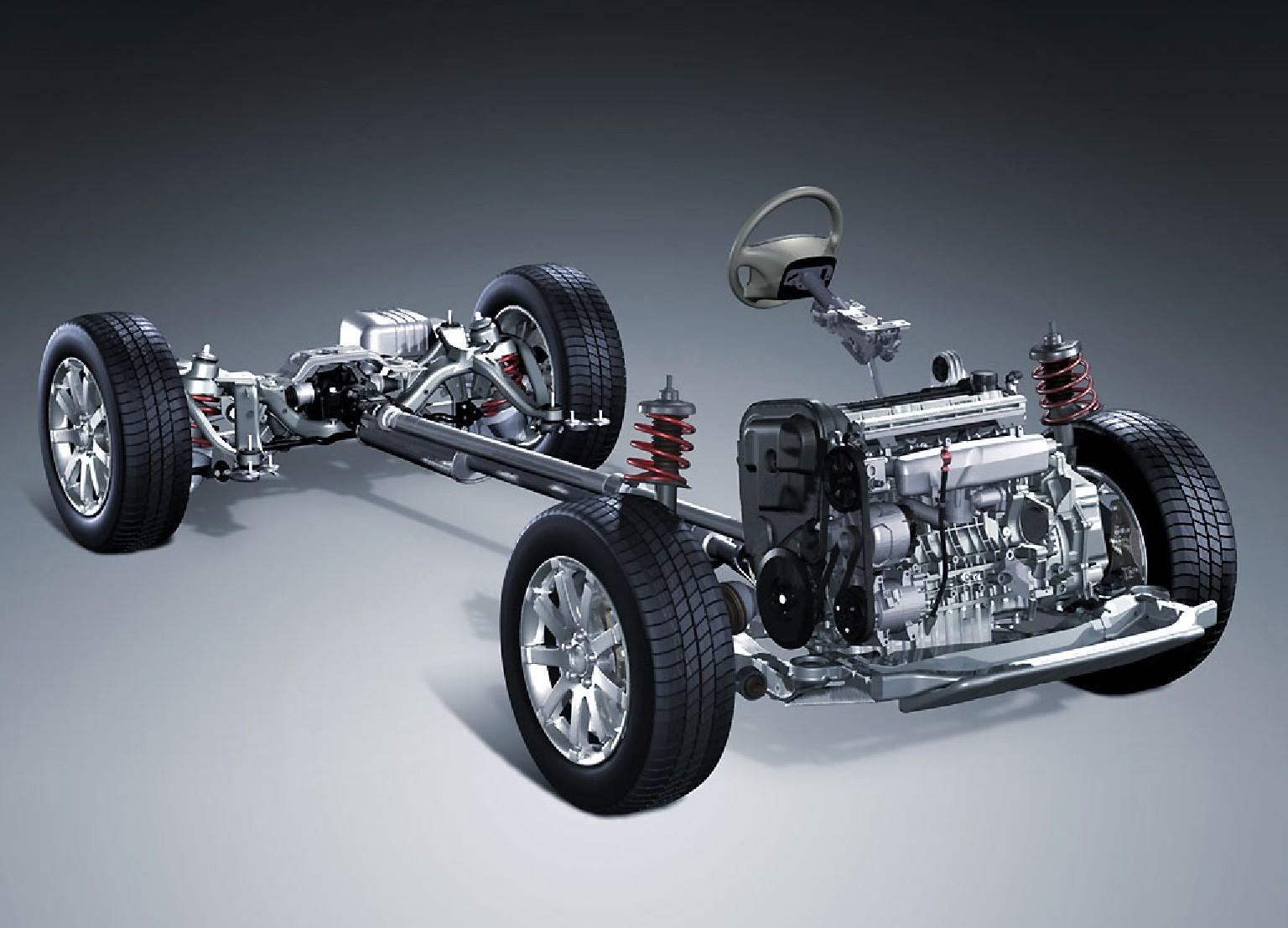

Every vehicle has a key part called the car chassis. It acts as the main structure, or the “vehicle skeleton,” that holds everything together. The chassis gives the car its shape, strength, and stability, making driving safe and smooth.

Understanding the Structure and Function of a Car Chassis

The car chassis has many important jobs. It must be strong to carry the car, its passengers, and cargo. It also needs to handle the forces of driving, like speeding up, stopping, and turning. The chassis affects how well the car handles and performs, helping the driver control it.

Different Types of Automotive Chassis: Monocoque vs. Ladder Frame

There are two main types of car chassis: monocoque and ladder frame. The monocoque is a single, lightweight structure that combines the body and frame. It’s used in many modern cars for better performance. On the other hand, the ladder frame is found in bigger vehicles like trucks and SUVs. It’s stronger and can carry more weight.

| Chassis Type | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|

| Monocoque | Passenger cars, sports cars | Lightweight, better handling, more efficient | Less durable, more complex to manufacture |

| Ladder Frame | Trucks, SUVs, commercial vehicles | Durable, high load-bearing capacity | Heavier, less responsive handling |

The Role of Car Chassis in Vehicle Safety and Performance

The car chassis is the foundation of a vehicle. Its design is key to safety and performance. Chassis safety is crucial for the vehicle’s structure and crash protection.

How the Chassis Impacts Vehicle Safety

The chassis spreads the vehicle’s weight evenly. This is vital for stability and control in emergencies or crashes. A good chassis design can absorb crash energy, protecting occupants.

It also keeps the passenger area safe. This reduces crash risks by preventing intrusion.

How the Chassis Affects Handling and Performance

The chassis design affects a vehicle’s handling and performance. Weight distribution, suspension, and rigidity are important. They influence how the car corners, accelerates, and brakes.

A well-designed chassis improves vehicle dynamics. This leads to better control and a more fun drive.

| Chassis Safety Considerations | Chassis Performance Factors |

|---|---|

|

|

In summary, the car chassis is vital for safety and performance. By focusing on key design elements, makers can create safe and fun vehicles.

Materials Used in Automotive Car Chassis Construction

The car chassis is the backbone of any vehicle. It’s made from different materials, each with its own benefits and drawbacks. As cars evolve, makers look for new chassis materials to make them stronger, lighter, and more efficient.

Steel vs. Aluminum Chassis: Pros and Cons

Steel has long been the top choice for car chassis construction. It’s strong and durable, fitting many vehicle types. But, steel makes cars heavier, which can hurt fuel efficiency and performance.

Aluminum chassis are becoming more popular, especially in luxury and sports cars. Aluminum is lighter, improving speed, handling, and fuel economy. Yet, aluminum frames might not be as strong as steel ones.

Innovations in Composite Chassis Materials

New composite materials are changing car chassis designs. Carbon fiber, a strong and light material, is used in high-performance cars. These composite frames are incredibly strong and light, making cars both agile and rigid.

| Material | Strength | Weight | Cost |

|---|---|---|---|

| Steel | High | Heavy | Low |

| Aluminum | Moderate | Light | Moderate |

| Carbon Fiber | Extremely High | Very Light | High |

The car industry’s push for lightweight construction and better performance will guide the choice of chassis materials. This will shape the future of car design.

How Car Chassis Are Designed for Different Vehicle Types

The chassis design is key in car engineering. It affects how a car performs, handles, and feels. Car makers carefully design each chassis for its vehicle type, like sports cars or SUVs. This section explores how engineers make each chassis unique to unlock the car’s full potential.

Designing Chassis for Sports Cars and Sedans

Sports cars and high-performance sedans need a special chassis. It must have a low center of gravity, be very rigid, and efficient aerodynamics. Car makers use chassis designs and vehicle-specific frames to boost performance chassis features. They aim to make the car feel quick, agile, and exciting to drive.

Designing Chassis for SUVs and Trucks

SUVs and trucks need a different chassis design. They focus on off-road skills, carrying heavy loads, and keeping passengers comfy. The chassis must be strong and stable for rough terrain and heavy cargo. This means using chassis designs and vehicle-specific frames to handle daily challenges.

“The chassis is the backbone of any vehicle, and its design is crucial in defining the overall character and capabilities of the car.”

Every vehicle’s chassis shows the skill and knowledge of car engineers. By customizing the chassis design, vehicle-specific frames, and performance chassis for each car, they craft a driving experience that’s both thrilling and useful.

The Future of Car Chassis: Trends in Lightweighting and Sustainability

The car industry is changing fast, thanks to electric vehicles (EVs) and a focus on green design. The car chassis is at the center of this change. It’s evolving to meet the needs of tomorrow.

How Electric Vehicles are Changing Chassis Design

EVs bring new challenges and chances for designers. They need to balance weight, save energy, and keep the car strong. New designs, like EV chassis with built-in batteries, are helping meet these needs.

Sustainable Materials and Technologies in Chassis Manufacturing

Sustainability is key in car making, and the chassis is no exception. Companies are using eco-friendly frames made from recycled stuff, light materials, and strong alloys. They’re also using new ways to make parts, like 3D printing, to cut waste and make cars better.

| Material | Advantages | Disadvantages |

|---|---|---|

| Aluminum | Lightweight, Corrosion-resistant | Higher cost, Complex manufacturing |

| Carbon Fiber | Extremely lightweight, High strength-to-weight ratio | Expensive, Specialized manufacturing |

| Recycled Plastics | Sustainable, Cost-effective | Lower strength, Limited applications |

The car chassis will be crucial in the future of cars. With EV chassis and eco-friendly frames, the industry is moving towards a greener, more efficient future.

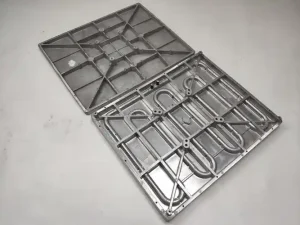

Choose Shixinproto for Precision Automotive Chassis Manufacturing

Shixinproto is a top choice for automotive chassis manufacturing. They use advanced prototyping and focus on precision engineering. This ensures high-quality chassis production.

Their facilities and technologies meet the highest standards. This means every chassis they make is top-notch.

Shixinproto’s team works hard from start to finish. They make sure all chassis parts fit together perfectly. This makes the manufacturing process smooth and efficient.

They pay close attention to detail and follow safety rules. This makes them a reliable partner for car makers.

Looking for chassis for sports cars, sedans, SUVs, or trucks? Shixinproto can make it happen. They focus on making chassis lighter and more eco-friendly. This means your cars will perform well and help the environment.

FAQ

What is a car chassis?

The car chassis is the main structure of a vehicle. It holds all other parts together. It gives the vehicle its shape and supports the body and other systems.

What are the different types of automotive chassis?

There are two main types of automotive chassis. The monocoque design combines the body and frame into one. The ladder frame design has a separate frame for the body to mount on.

How does the chassis impact vehicle safety and performance?

The chassis is key to vehicle safety. It helps in crash protection and energy absorption. It also affects how the vehicle handles and performs.

What materials are used in automotive chassis construction?

Chassis are often made from steel. But, aluminum is used for lighter designs. Newer cars also use carbon fiber for high performance.

How are chassis designed for different vehicle types?

Chassis designs vary by vehicle type. Sports cars and sedans focus on low center of gravity and aerodynamics. SUVs and trucks need strength for off-road use and carrying heavy loads.

How is the future of automotive chassis evolving?

Electric vehicles are changing chassis design. New designs must consider battery placement and weight. Car makers are also working on making chassis lighter and using eco-friendly materials.