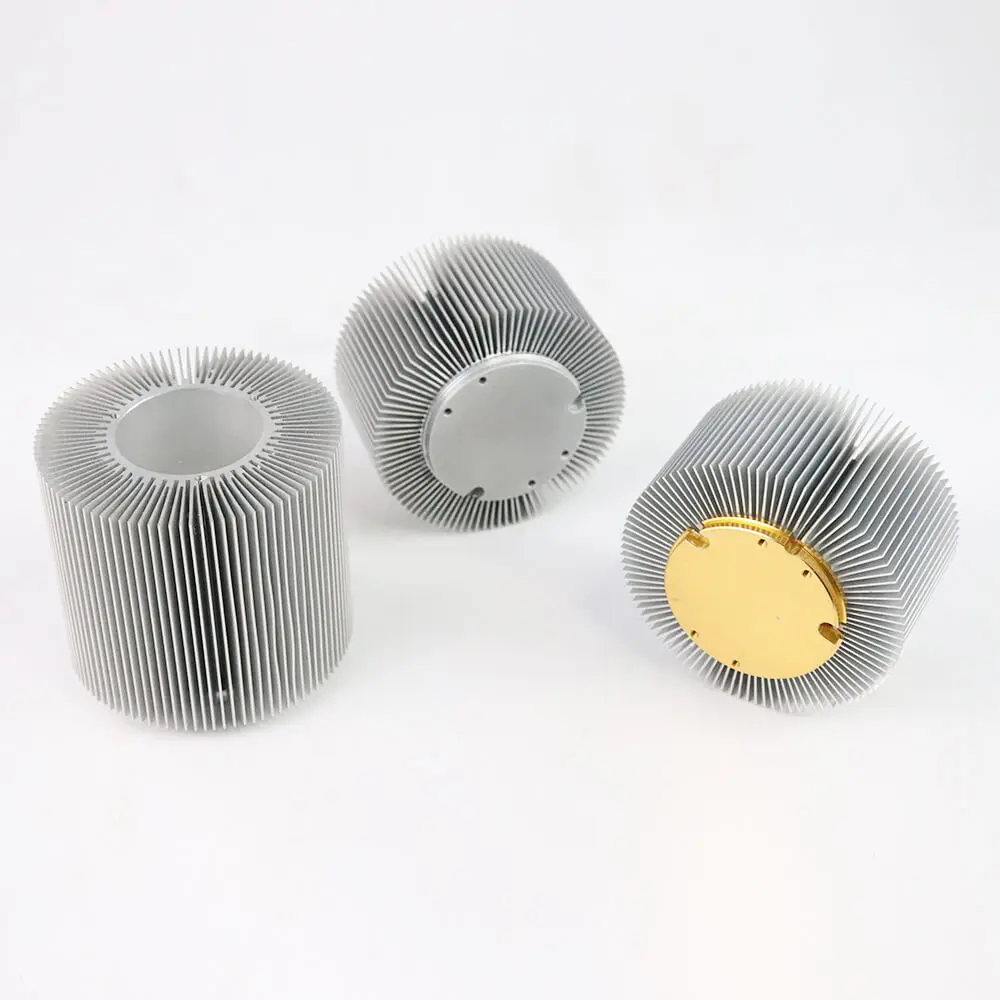

Home » Shop » Heat Sink » Aluminum Heat Sink » Cheap CNC Milling Service OEM Customized Extruded Aluminum Die Casting Heat Sink

Product Description

-

Service Advantages:

- Cost-effective: We offer a cheap CNC milling service that can effectively reduce production costs while ensuring the processing quality, helping customers save expenses. It is especially suitable for cost-sensitive projects.

- High-precision Machining: With advanced CNC milling technology, high-precision processing can be achieved, ensuring the dimensional accuracy and surface quality of the heat sink, thus improving its performance and reliability.

- Customization Service: We provide OEM customization services. According to the specific needs of customers, we can customize extruded aluminum die casting heat sinks with different shapes, sizes, and structures to meet the requirements of various special application scenarios.

-

Product Features:

- Excellent Heat Dissipation Performance: The extruded aluminum die casting process endows the heat sink with good thermal conductivity and heat dissipation effect, which can effectively dissipate heat and ensure the normal operation of the equipment.

- High Strength and Durability: Made of high-quality aluminum alloy and processed by the die casting technique, the heat sink has relatively high strength and hardness. It can withstand large pressure and impact forces and is not prone to deformation and damage.

- Lightweight Design: Aluminum alloy has a relatively low density, making the heat sink lightweight. It is convenient for installation and transportation and will not impose an excessive burden on the overall weight of the equipment.

- Good Corrosion Resistance: The surface of the aluminum alloy has undergone special treatment and has good corrosion resistance. It can be used for a long time under harsh environmental conditions, extending the service life of the heat sink.

-

Application Areas:

- Electronic Equipment: It is widely used for heat dissipation of electronic devices such as computer CPUs, graphics cards, and power supplies. It can effectively reduce the temperature of the equipment and improve its performance and stability.

- Communication Equipment: Communication equipment like base stations, switches, and routers generates a large amount of heat during operation. Efficient heat sinks are needed to ensure the normal operation of the equipment, and extruded aluminum die casting heat sinks are an ideal choice for heat dissipation in communication equipment.

- Industrial Automation: In the field of industrial automation, such as robots and automated production lines, heat sinks are also required to ensure the stable operation of the equipment and improve production efficiency.

- New Energy Vehicles: With the development of new energy vehicles, the requirements for heat dissipation of automotive electronic equipment are becoming higher and higher. Extruded aluminum die casting heat sinks can be used for heat dissipation of battery management systems, motor controllers, and other equipment in new energy vehicles, providing strong support for the development of new energy vehicles.

-

Cooperation Process:

- Requirement Communication: Customers communicate with our professional team and put forward specific product requirements and technical requirements.

- Scheme Design: Based on the customers’ requirements, our engineer team will design a customized heat sink scheme and provide detailed technical drawings and quotations.

- Sample Production: After the customers confirm the scheme and quotation, we will produce samples for the customers to test and evaluate to ensure that the products meet the customers’ requirements.

- Mass Production: After the customers are satisfied with the samples, we will conduct mass production according to the order requirements of the customers and conduct strict quality inspection in strict accordance with the quality control system to ensure stable and reliable product quality.

- After-sales Service: We provide comprehensive after-sales service, including product quality assurance, technical support, and after-sales maintenance, to relieve customers of their worries.

Related products

-

IP67 Aluminum Box Industrial Electric Die Casting Aluminum Enclosure Extruded Aluminum Heatsink Enclosure

Read more -

40x40x11mm Aluminum Heat Sink Cooler 3D Printer Accessories

Read more -

LED Light Round Heatsink Cold Forge Heat Sink High Power Extruded Aluminum CNC 9*9*5cm OEM ODM

Read more -

Extruder Aluminum Heat Sink Cooling Block 41x20x13mm Heat Sink

Read more