5-axis CNC machining is changing the game in modern manufacturing. It’s a cutting-edge technology that makes creating complex parts easier. It uses advanced CNC technology to improve precision and efficiency.

This technique is key for industries looking to innovate. It allows for intricate geometries that were once impossible. This guide will cover everything you need to know about 5-axis CNC machining.

It will explore its features, benefits, and uses in different fields. By learning about 5-axis CNC machining, you can make better decisions. This knowledge will help you improve your manufacturing processes.

What Is 5-Axis CNC Machining?

In the world of manufacturing, 5-axis CNC machining is a big deal. It’s a step up from the usual 3-axis machines. This tech offers unmatched precision and flexibility.

Understanding the Basics of 5-Axis Machining

5-axis CNC machines can move in five directions, not just three. They can tilt and rotate the workpiece or tool. This lets them make complex parts with great accuracy.

Key Features of 5-Axis CNC Machines

What makes 5-axis CNC machines special is their rotary table. It lets you control the workpiece’s position precisely. This feature also means you can machine parts from different angles.

This setup makes 5-axis CNC machines very efficient. They can make parts with tricky shapes that 3-axis machines can’t. This means less work in the end and better results.

| Feature | Benefit |

|---|---|

| Simultaneous 5-axis machining | Allows for the creation of complex and intricate parts with a high degree of accuracy |

| Rotary table | Enables precise control of the workpiece’s orientation, facilitating the production of parts with undercuts and deep cavities |

| Ability to machine parts from multiple angles | Streamlines the manufacturing process and reduces the need for secondary operations |

Advantages of 5-Axis CNC Machining

5-axis CNC machining brings many benefits to the manufacturing world. It improves precision and efficiency and makes it easier to work on complex parts.

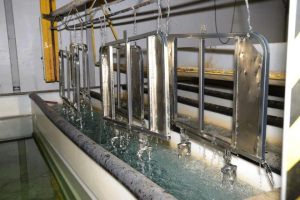

Increased Precision and Efficiency

One key advantage is the improved surface finish and reduced setup time. With five-axis technology, makers can get parts done faster and with less error. This means better quality and a smoother production flow.

Capability to Machine Complex Geometries

5-axis CNC machining is great for making complex parts. It can handle shapes and details that 3-axis machines can’t. This lets makers create parts that were hard or impossible before.

| Feature | Benefit |

|---|---|

| Increased Precision | Improved surface finish and tighter tolerances |

| Reduced Setup Time | Streamlined production workflow and increased efficiency |

| Complex Parts Manufacturing | Ability to create intricate geometries and shapes |

“The advantages of 5-axis CNC machining are truly game-changing, allowing us to push the boundaries of what’s possible in modern manufacturing.”

– Jane Doe, Manufacturing Engineer

Applications of 5-Axis CNC Machining

5-axis CNC machining is a game-changer in many industries. It’s used for everything from aerospace parts to medical implants and car parts. This method is changing how companies tackle tough fabrication tasks.

Industries That Benefit from 5-Axis CNC

Many industries use 5-axis CNC machining. These include:

- Aerospace, for making complex engine parts and turbine blades

- Medical, for creating custom implants and surgical tools

- Automotive, for precise engine parts and body panels

- Electronics, for making detailed circuit boards and enclosures

- Tooling and die-making, for making accurate molds and dies

Use Cases of 5-Axis Machines in Various Sectors

5-axis CNC machining has many uses. In aerospace, it helps make complex parts like turbine blades. This ensures they fit perfectly and work well. In medicine, it’s used for making custom implants and prosthetics. This meets each patient’s specific needs.

In the car world, it’s key for making precise engine parts and detailed body panels. It also helps in creating advanced electronic system housings.

| Industry | Application | Benefit of 5-Axis CNC |

|---|---|---|

| Aerospace | Turbine blades, engine parts | Precise fabrication of complex geometries |

| Medical | Orthopedic implants, prosthetics | Customized production for individual patients |

| Automotive | Engine components, body panels, electronics housings | High-precision manufacturing of intricate parts |

5-axis CNC machining is incredibly versatile. It’s changing how businesses tackle complex tasks in many fields. This includes aerospace, medical, and automotive industries.

Choosing the Right 5-Axis CNC Machine for Your Needs

Choosing the right 5-axis CNC machine is key for your manufacturing needs. A good choice can boost your production, part quality, and success. Let’s look at the main factors to consider when picking a 5-axis CNC machine.

Factors to Consider When Choosing a 5-Axis Machine

When picking a 5-axis CNC machine, know your specific needs well. Important factors include:

- Machine specifications: Check the machine’s workpiece size capacity, tool changing abilities, and its five-axis motion range.

- Precision and accuracy: Find out how precise and accurate you need your parts. Choose a machine that meets these standards.

- Production volume: Think about how much you plan to produce. Pick a 5-axis CNC machine that can handle your volume well.

- Automation features: Look at the machine’s automation tech, like robotic part handling. This can make your workflow smoother.

5-Axis vs. 3-Axis Machines: Which is Right for You?

Choosing between a 5-axis and a 3-axis CNC machine needs careful thought. Each has its own benefits and uses.

5-axis CNC machines are great for precision and complex geometries. They’re perfect for aerospace, medical, and high-end automotive. But, they cost more and need more training.

3-axis CNC machines are cheaper and easier to use. They’re good for simpler tasks or small production runs. They’re a cost-effective choice for less complex needs.

| Feature | 5-Axis CNC Machine | 3-Axis CNC Machine |

|---|---|---|

| Workpiece size | Larger, more complex geometries | Typically smaller and less complex |

| Precision | Higher, capable of complex parts | Lower, suitable for simpler parts |

| Tool changing | Advanced, with more flexibility | Basic, with limited flexibility |

| Cost | Higher initial investment | Lower initial investment |

| Operator skill | Requires more training and experience | Easier to operate with less training |

The choice between a 5-axis and a 3-axis CNC machine depends on your needs, budget, and part complexity.

Why Shixinproto is the Right Partner for Your 5-Axis Machining Needs

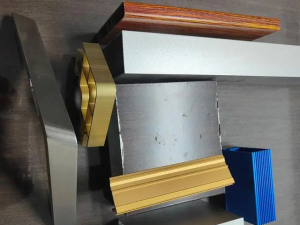

At Shixinproto, we’re proud of our top-notch 5-axis CNC machining skills. We’re a leading name in precision machining, known for our custom parts and solutions. Our advanced tools and team of expert machinists make complex tasks easy for us.

Our Expertise in 5-Axis CNC for Complex Parts

Our 5-axis CNC machines are perfect for detailed shapes and tight tolerances. Our engineering team works with clients to create custom solutions. We handle everything from aerospace parts to medical components with high precision and efficiency.

We’re always updating our tech and training our team at Shixinproto. This keeps us ahead in the precision machining world. We help turn your ideas into real products, from prototypes to large-scale production.