Welding is a key skill with many techniques to choose from. We’ll look at the main differences between arc, TIG, and MIG welding. Knowing what each method does best will help you pick the right one for your project.

If you’re into welding for work or fun, this guide is for you. We’ll compare TIG’s clean welds, MIG’s versatility, and arc’s reliability. Find out which welding method is best for you.

Key Differences Between Arc, MIG, and TIG Welding

It’s important to know the differences between arc, MIG, and TIG welding. This knowledge helps you choose the best method for your project. Let’s explore what makes each process unique.

What is Arc Welding?

Arc welding uses an electric arc to join metal pieces. It’s great for working with many materials, from thin sheets to thick plates. This makes it a favorite for many projects.

MIG vs TIG: What Makes Them Different?

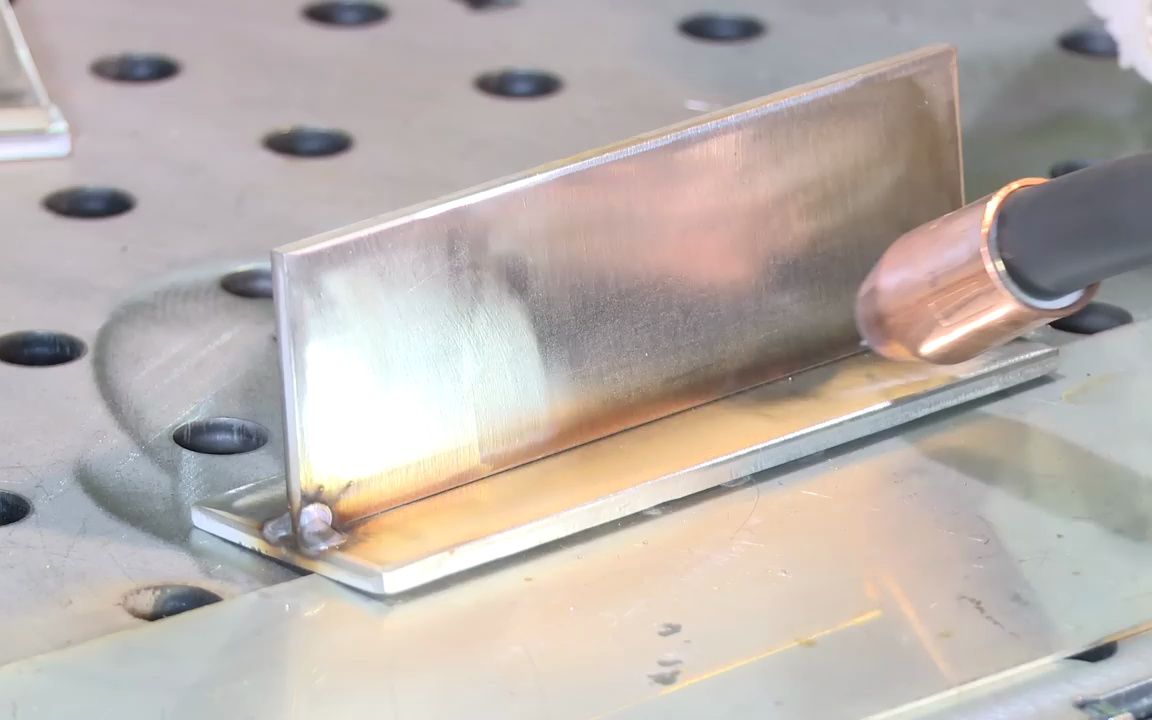

MIG welding, or gas metal arc welding (GMAW), uses a wire electrode and shielding gas. It’s known for its fast welding and easy learning curve. This makes it a popular choice for many.

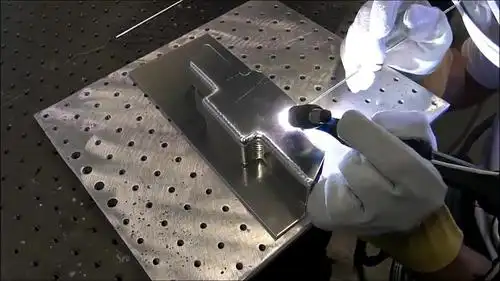

TIG welding is famous for its precise, high-quality welds. It’s the go-to for critical projects and thin materials. TIG welding needs a non-consumable tungsten electrode and shielding gas for its detailed work.

| Feature | MIG Welding | TIG Welding |

|---|---|---|

| Welding Equipment | Requires a welding gun, wire feeder, and shielding gas | Requires a torch, tungsten electrode, and shielding gas |

| Welding Speed | Faster welding speed | Slower welding speed |

| Weld Quality | Produces uniform, smooth welds | Produces high-quality, precise welds |

| Skill Level | Easier to learn and master | Requires more skill and practice |

Choosing the right welding method depends on several factors. These include the materials, the quality of weld you need, and your skill level. Knowing the unique traits of arc, MIG, and TIG welding helps you make the best choice. This ensures your welding projects are successful.

When to Use Each Type of Welding

In the world of welding, each technique has its own strengths. It’s important to know when to use MIG welding, TIG welding, or arc welding. This ensures your project turns out the best it can.

Best Uses for MIG Welding

MIG welding is great for projects that need speed and efficiency. It works well with many materials like steel, aluminum, and stainless steel. This makes it perfect for car repairs, building, and other fabrication tasks.

MIG welding is also easy to learn. This is why both pros and DIYers love it.

Advantages of TIG for Precision Welding

TIG welding precision is unmatched. It’s perfect for thin materials and where looks matter. TIG welding is ideal for aluminum, stainless steel, and other metals.

It offers precise control and clean welds. This makes it a top choice for detailed work.

Why Choose Arc Welding for Outdoor Work?

Arc welding outdoors is great for tough, outdoor jobs. Arc welding, or stick welding, is strong and reliable. It’s perfect for construction and repair jobs.

It also handles welding material compatibility well. Plus, it works well in windy or damp conditions. This makes arc welding a versatile choice for outdoor welding.

How to Choose the Right Welding Method for Your Project

Choosing the right welding method is key for your project’s success. It affects the quality, cost, and outcome. Whether you’re new or experienced, knowing what to look for is crucial.

Selecting the Best Option for Beginners

For beginners, picking a beginner-friendly method is vital. MIG welding is a good start. It’s easier to learn and requires less skill than other methods.

Cost Considerations: MIG, TIG, or Arc Welding?

Costs vary with each welding method. MIG welding is often cheaper, with lower costs for equipment and materials. TIG welding may cost more upfront but can lead to better welds and save money in the long run. Arc welding is a middle ground, balancing cost and welding skill requirements.

Choosing the right welding method depends on your project, skills, and budget. By weighing these factors, you can pick the welding method that meets your needs and goals.

Shixinproto’s Welding Services: Find the Right Fit for Your Needs

At Shixinproto, we’re proud of our welding skills. We handle everything from big industrial projects to custom jobs. Our team is ready for any challenge, from detailed TIG welding to strong MIG welding.

We know each industry has its own needs. Our experts work with you to find the best welding method. This ensures your project works well and lasts a long time. We’re trusted by many businesses, from construction to cars.

Our secret to great welding is combining advanced techniques with careful attention. Whether you’re experienced or new, we’re here to help. Reach out to us to see how we can improve your project.