In the world of manufacturing, CNC machining and manual machining are key players. Both are vital in creating the products we use every day. Knowing the differences between them is crucial for businesses looking to improve their production.

This article will explore the unique traits of CNC and manual machining. We’ll look at their strengths, weaknesses, and uses. Whether you’re an experienced manufacturer or just starting out, this guide will help you choose the right machining method for your needs.

What is CNC Machining?

Computer numerical control (CNC) machining is a game-changing method in making products. It uses computer-controlled machines to make parts with great precision and speed. This technology has changed how we make things.

Definition of CNC Machining

CNC machining uses computers and machines to make parts and products. It programs machines to work on their own, cutting down on manual work. This makes production faster and more efficient.

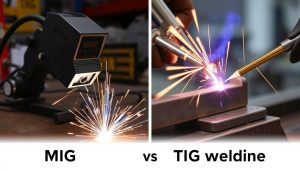

Types of CNC Machines

The CNC world has many machines, each for different tasks. Here are some common ones:

- CNC milling machines – These machines shape, drill, and cut materials like metals, plastics, and wood.

- CNC turning machines – They make round parts by moving the workpiece against a tool.

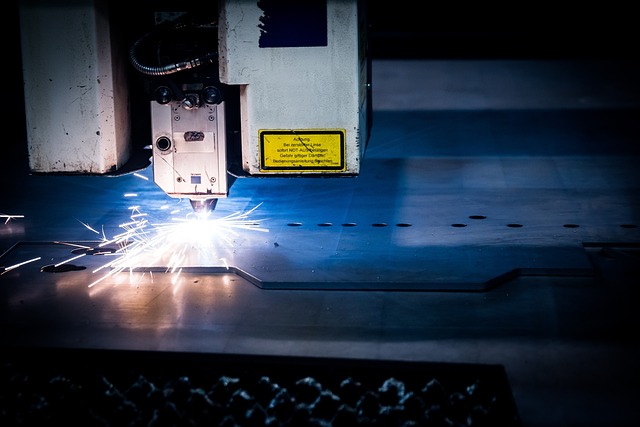

- CNC laser cutters – High-powered lasers cut and shape materials, perfect for detailed designs.

- CNC plasma cutters – These machines use a plasma arc to quickly cut through metal.

Benefits of CNC Machining

CNC machining offers many benefits, making it a top choice for making things. Here are some key advantages:

- It improves precision and accuracy – CNC machines make parts with tighter tolerances and better finishes.

- It boosts productivity and efficiency – CNC systems work all day, every day, with little downtime, increasing output.

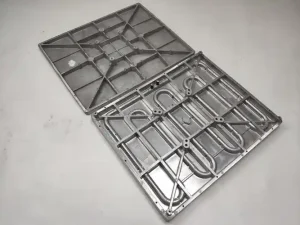

- It increases design flexibility – CNC tech lets us make complex parts that are hard or impossible to make by hand.

- It lowers labor costs – CNC machining needs fewer people, saving on labor costs.

By using CNC, makers can make their production better, faster, and more competitive in today’s fast world.

What is Manual Machining?

Manual machining is different from CNC machining. It uses the skills of human operators. They control conventional machining tools like manual lathes and milling machines to make detailed parts.

Overview of Manual Machining

Manual machining is hard work. Skilled machinists use their know-how to shape and finish parts. Unlike CNC machines, they control the tools by hand. This means they adjust the speed and depth of cut themselves.

Common Manual Machining Tools

- Manual lathes: These machines help turn, drill, and grind round parts with great precision.

- Milling machines: Machinists use these tools to cut, shape, and drill flat and complex surfaces.

- Hand tools: Skilled workers use tools like files, hammers, and wrenches for fine details and finishing.

Advantages and Limitations of Manual Machining

Manual machining has its perks. It’s great for making unique parts and can adapt to new needs. But, it takes more time and effort than CNC machining. The quality can also vary, depending on the machinist’s skills.

Key Differences Between CNC Machining and Manual Machining

Choosing between CNC machining and manual machining affects your product’s quality. Each method has its own strengths and weaknesses. It’s important to know what they are.

Precision and Accuracy

CNC machining is known for its machining accuracy. It makes parts with tighter tolerances and smoother finishes than manual machining. This is because CNC uses advanced computer technology for consistent results, even with complex shapes.

Speed and Efficiency

CNC machining is faster and more efficient because it’s automated. This makes it great for making lots of parts quickly. Manual machining, however, takes more time and effort, especially for big projects.

Cost Considerations

Even though CNC machines cost more upfront, they can save money in the long run. They need less labor and work faster. Manual machining might be cheaper for small jobs but gets expensive for bigger, more complex projects.

Complexity and Versatility

CNC machining is excellent at making complex geometries and detailed designs. Its advanced programming makes it versatile. Manual machining, while skilled, is less flexible and takes longer to set up for complex parts.

| Metric | CNC Machining | Manual Machining |

|---|---|---|

| Machining Accuracy | Exceptional, with tight tolerances | Varying, depending on the skill of the operator |

| Production Speed | Highly efficient, suitable for high-volume production | Slower, more labor-intensive |

| Manufacturing Costs | Potentially lower due to reduced labor requirements | More cost-effective for small-scale projects |

| Complexity and Versatility | Capable of handling complex geometries and intricate designs | More limited in tackling complex parts |

Knowing the differences between CNC and manual machining is key. It helps decide which method is best for your project. Whether you need machining accuracy, production speed, manufacturing costs, or complex geometries, understanding these differences is crucial.

When to Choose CNC Machining Over Manual Machining

In the world of manufacturing, choosing between CNC machining and manual machining depends on your project’s needs. CNC machining is often the better choice in certain situations.

When Precision is Key

CNC machining is top-notch for making precise parts. Its computerized systems allow for unmatched accuracy and consistency. This is crucial in industries like aerospace, medical, and automotive, where small errors can be big problems.

High-Volume Production Runs

For big production jobs, CNC machining is unbeatable. It’s faster and more efficient than manual machining. CNC machines can work non-stop, making high-quality parts consistently. This is perfect for large-scale production where high-precision parts are needed.

| Scenario | CNC Machining | Manual Machining |

|---|---|---|

| Precision | Exceptional accuracy and repeatability | Dependent on operator skill |

| Production Volume | Ideal for high-volume, consistent output | Better suited for low-volume, custom work |

| Cost | Higher upfront investment, lower per-unit costs | Lower initial investment, higher per-unit costs |

| Complexity | Capable of producing complex, intricate parts | Limited to relatively simpler geometries |

Think about your project’s needs to decide between CNC machining and manual machining.

Shixinproto’s CNC Machining Services: Why Choose Us?

At Shixinproto, we’re a top choice for CNC machining services. We have the latest equipment and a team of experts. We aim to deliver top-notch quality and precision in every project.

Need custom parts manufacturing or complex prototypes? Shixinproto can make it happen. Our CNC machines handle big or small projects with precision and care.

What makes us stand out is our dedication to making customers happy. We listen to what you need and offer solutions that fit perfectly. From start to finish, our team is here to help. You can expect a smooth and stress-free experience with us.

FAQ

What is the difference between CNC machining and manual machining?

CNC machining uses computer-controlled machines for high accuracy. Manual machining relies on skilled operators for parts by hand.

What are the advantages of CNC machining over manual machining?

CNC machining is more precise and faster. It can make complex shapes. CNC machines work longer without getting tired, making production more consistent.

When is manual machining preferred over CNC machining?

Manual machining is better for small batches or custom parts. It’s also cheaper for simple parts or small runs.

How do the costs of CNC machining and manual machining compare?

CNC machining costs more upfront but is cheaper for large runs. Manual machining is less expensive initially but takes more time and labor for complex parts.

What types of CNC machines are commonly used in manufacturing?

Common CNC machines include mills, lathes, routers, and plasma cutters. Each is for specific tasks like milling or cutting.

What are the common tools used in manual machining?

Manual machining uses tools like lathes, milling machines, and hand tools. Skilled machinists operate these to create parts.