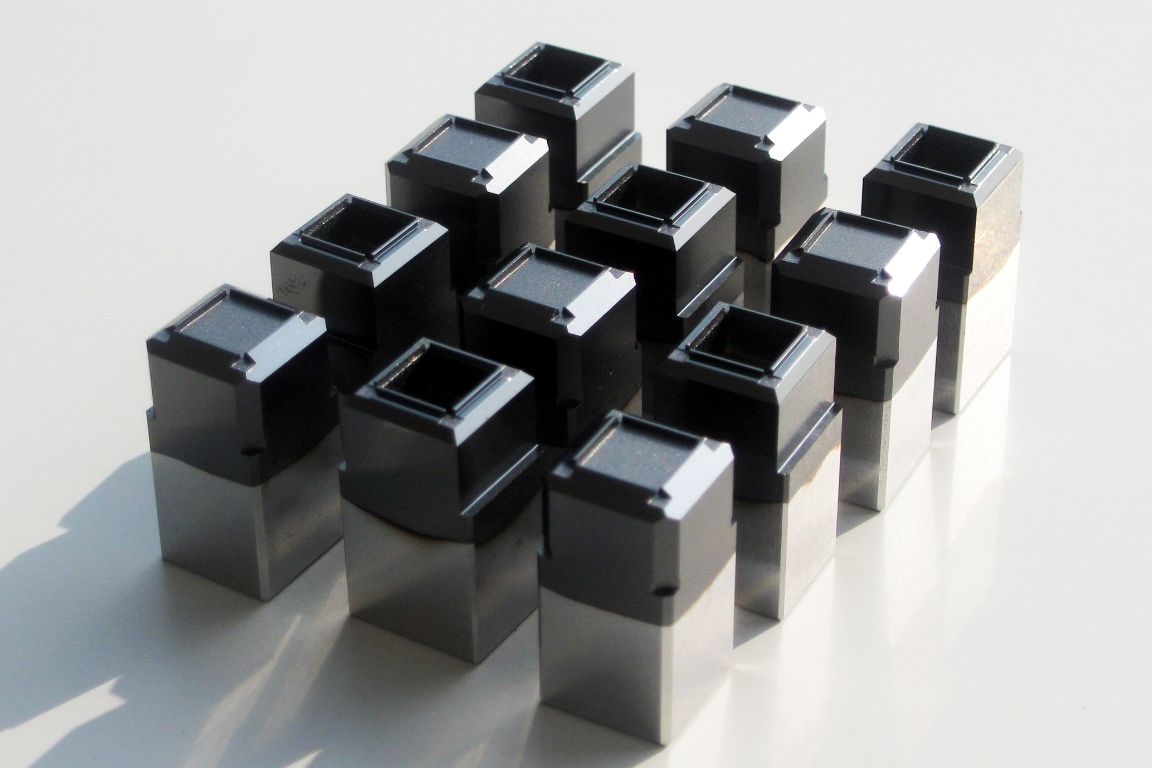

The black oxide finish makes metal surfaces more durable and attractive. It’s a top pick for many industries. This treatment boosts metal’s resistance to corrosion and gives it a sleek, matte black look. We’ll dive into its benefits and uses in fields like aerospace and cars.

The black oxide finish changes metal parts’ surface through chemical reactions. It creates a strong, corrosion-resistant layer. This process turns the metal black, making products last longer or look better. It’s a great choice for improving durability or adding style.

What is Black Oxide Coating?

Black oxide coating is a way to protect metal surfaces. It creates a layer that stops corrosion. This layer also makes the metal look matte black, improving its look and protecting it from damage.

Overview of the Black Oxide Process

The black oxide process changes metal surfaces through chemicals. First, the metal is cleaned and then put in a hot, alkaline solution. This solution turns the metal’s surface into a thin, black iron oxide layer.

Chemical Reactions Involved in Black Oxide Finishing

The black oxide process uses chemical reactions to protect metal. Iron on the metal’s surface reacts with oxygen to form iron oxide. This creates a strong, protective layer against moisture, chemicals, and wear.

| Reaction Step | Chemical Equation |

|---|---|

| Oxidation of Iron | 3Fe + 4H2O → Fe3O4 + 8H+ + 8e– |

| Formation of Iron Oxide (Magnetite) | Fe2+ + 2Fe3+ + 8OH– → Fe3O4 + 4H2O |

Benefits of Black Oxide Coating

Black oxide finishes have many advantages. They improve wear resistance, offer dimensional stability, and have anti-galling properties. This coating is versatile and provides excellent performance and protection.

Corrosion Resistance and Durability

Black oxide coatings are great at fighting corrosion. The chemical process creates a strong, even layer. This layer protects metal parts from moisture, chemicals, and the environment.

This corrosion resistance makes parts last longer. It means you don’t have to replace them as often.

Aesthetic Appeal: Matte Black Surface Finish

Black oxide coating also looks good. It has a matte black finish that looks sleek and professional. This aesthetic appeal is great for many industrial and mechanical uses.

| Benefit | Description |

|---|---|

| Wear Resistance | The black oxide coating enhances the wear resistance of metal components, helping to maintain their integrity and functionality over time. |

| Dimensional Stability | The coating process ensures dimensional stability, ensuring that parts retain their precise measurements and fit seamlessly into their intended applications. |

| Anti-Galling Properties | Black oxide finishes possess anti-galling properties, reducing the risk of seizure, binding, or damage between moving metal surfaces. |

“Black oxide coatings provide a unique combination of functional and aesthetic benefits that make them a valuable asset in a wide range of industries.”

Applications of Black Oxide in Manufacturing

Black oxide coating is more than just a pretty finish. It’s used in many fields, like aerospace, automotive, and even in consumer products and military gear. Let’s dive into how black oxide is used in today’s manufacturing world.

Black Oxide in the Aerospace Industry

In aerospace, black oxide is key for parts needing to fight off corrosion and look uniform. It’s used on aircraft parts like landing gear, fasteners, and engine parts. This helps them last longer in the tough skies.

Black Oxide Coating for Automotive Parts and Tools

The car world also loves black oxide. It’s put on brakes, suspension parts, and more. Plus, it’s great for tools and consumer product gear, making them both safe and visually appealing.

| Industry | Black Oxide Applications |

|---|---|

| Aerospace | Landing gear, fasteners, engine components |

| Automotive | Brakes, suspension systems, hardware |

| Industrial and Consumer Products | Tools, equipment, military equipment |

Black oxide coating is a real game-changer. It boosts both looks and function in a variety of industrial applications. From precise aerospace parts to tough consumer products and military equipment, it’s a versatile hero.

How to Apply Black Oxide Coating

Getting a top-notch black oxide finish needs careful steps. This part talks about the DIY vs. professional methods and the main steps to apply it.

DIY vs. Professional Black Oxide Coating Services

Applying a black oxide finish at home is possible with DIY kits. But, it’s complex and needs careful control over surface preparation, hot oxide process, and cold blackening. Professional services give better results because they have the right tools, know-how, and quality checks for a great finish.

Steps Involved in Applying Black Oxide Finish

- Surface Preparation: Cleaning and preparing the surface is key for a lasting black oxide finish. This means cleaning, degreasing, and sometimes etching or pickling to remove dirt or old oxides.

- Hot Oxide Process: Metal parts are dipped in a hot alkaline solution. This creates a thin, strong black oxide layer on the surface.

- Cold Blackening: A cold blackening step is added to improve the look and protection of the coating.

Each step in the black oxide application needs a lot of detail and precision. This is why many choose professional services, even DIY fans.

Black Oxide vs. Other Surface Finishes

Choosing the right surface finish for your products is key. Black oxide, zinc plating, anodizing, and powder coating are popular choices. Each has its own pros and cons. Let’s explore them to help you decide based on your needs and budget.

Corrosion Resistance

Black oxide is great for fighting corrosion, especially in tough environments. But, anodizing might offer even better protection, especially near the sea.

Aesthetic Appeal

Black oxide gives a sleek, matte black look that’s hard to match. Powder coating, though, lets you choose from many colors. This way, you can make your products look exactly as you want.

Cost-Effectiveness

| Surface Finish | Cost-Effectiveness |

|---|---|

| Black Oxide | Cost-effective, especially for high-volume production |

| Zinc Plating | Moderately cost-effective, suitable for medium-scale production |

| Anodizing | Relatively more expensive, better suited for low-volume or specialized applications |

| Powder Coating | Versatile and cost-effective, especially for custom color requirements |

By comparing the surface treatment comparison, finish selection criteria, and cost-effectiveness of each, you can choose wisely. This ensures your products meet your needs and budget.

Why Choose Shixinproto for Black Oxide Finishing Services?

At Shixinproto, we’re proud to offer top-notch finishing services. Our team has years of experience in black oxide coating. We ensure every project meets the highest quality and precision standards.

Whether you’re in aerospace, automotive, or any other field, trust Shixinproto. We provide customized solutions that go beyond your expectations.

We’re all about quality assurance. Our quality control measures are strict, from start to finish. This means you get a flawless black oxide finish that boosts durability and looks great.

Shixinproto knows every customer is different. We listen to your needs and tailor our services just for you. Our experts will work with you to create solutions that match your vision perfectly.

FAQ

What is black oxide coating?

Black oxide coating is a way to protect metal surfaces. It makes metal parts last longer and look better. This is done through a chemical process that gives them a matte black finish.

What are the benefits of black oxide coating?

It’s great for fighting corrosion and wear. It also looks good with its matte black finish. Plus, it keeps metal parts stable and prevents them from sticking together.

Where is black oxide coating used?

It’s used in many places, like in planes, cars, and tools. It helps metal parts work better and last longer.

How is black oxide coating applied?

You can do it yourself or get a pro to do it. First, you prepare the surface. Then, you use hot oxide or cold blackening to add the black finish.

How does black oxide coating compare to other surface finishes?

It’s better than zinc plating, anodizing, and powder coating in some ways. It’s cheaper and keeps metal parts stable. The right finish depends on what you need.

Why choose Shixinproto for black oxide finishing services?

Shixinproto is top-notch for black oxide finishing. They know their stuff, ensure quality, and tailor services for different needs. They’re all about being the best and making customers happy.