In the world of medical device making, precision and following rules are key. CNC (Computer Numerical Control) machine services are vital for creating top-notch medical devices. These devices must meet strict standards. As medical technology advances, the need for reliable CNC machining grows.

CNC machining is a game-changer in medical device making. It allows for the creation of complex parts with great accuracy. This is crucial for making things like orthopedic implants and surgical tools.

Regulatory compliance is also very important in medical devices. CNC services must follow strict rules from bodies like the FDA and ISO 13485. This ensures that medical devices are not only precise but also meet all necessary regulations.

How CNC Machining Supports the Medical Device Industry

The medical device industry is always changing, needing precision and reliability. CNC machining is key in making complex medical parts. It ensures parts are made consistently and meet medical standards.

The Importance of Precision in Medical Devices

Medical devices, like surgical tools and implants, must be precise. CNC machining is great at making parts with small details and exact fits. This precision is vital for the safety and effectiveness of medical devices.

CNC’s Role in Creating Complex Medical Components

The medical field often needs parts with many features. CNC machining can handle these complex tasks. It uses advanced tools and programming to make parts with detailed shapes and designs.

| Advantage | Benefit |

|---|---|

| Precision Manufacturing | Ensures accurate fit and function of medical devices |

| Complex Component Capabilities | Enables the creation of intricate medical parts |

| Consistent Quality | Produces reliable, high-quality medical components |

CNC machining is a game-changer for the medical device industry. It allows for the creation of innovative, safe, and effective products. These products greatly improve patient care and change lives.

Common CNC Machining Processes in Medical Device Manufacturing

The medical device industry needs precision to ensure quality and safety. CNC machining is key, offering specialized techniques for the medical field.

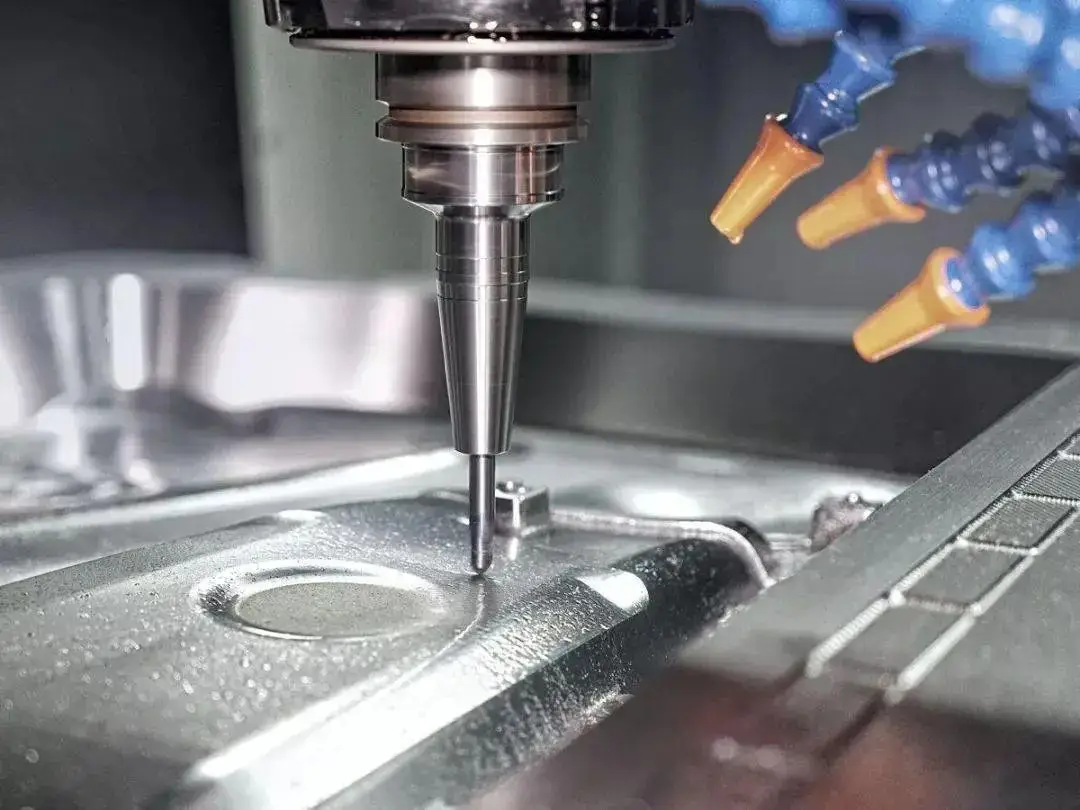

CNC Milling for Medical Implants and Surgical Instruments

CNC milling is versatile in making medical implants and surgical instruments. It creates complex designs with high accuracy. This is crucial for devices like orthopedic joints and dental prosthetics.

CNC Turning for Medical Devices with Tight Tolerances

CNC turning is vital for devices needing tight tolerances and complex shapes. It makes components with high dimensional accuracy. This is important for cardiovascular and neurological devices.

CNC Wire EDM for Highly Precise Medical Components

CNC Wire EDM is perfect for precise components. It uses a thin wire to cut and shape parts. This is ideal for complex medical implants and tools.

| CNC Machining Process | Medical Device Applications | Key Benefits |

|---|---|---|

| CNC Milling | Medical implants, surgical instruments | Precise, complex designs, repeatability |

| CNC Turning | Cardiovascular and neurological devices | Tight tolerances, complex geometries |

| CNC Wire EDM | Intricate medical implants, surgical tools | High precision, complex part fabrication |

Using these CNC machining processes, manufacturers can make high-quality, safe products. These meet the industry’s strict standards.

Regulatory Requirements for CNC Machining in Medical Devices

Medical device makers aim for precision and quality. They must navigate complex rules to meet these goals. This includes FDA regulations and ISO 13485 standards. The CNC machining world needs to keep up with these rules to protect patients.

FDA Regulations for CNC-Made Medical Parts

The U.S. Food and Drug Administration (FDA) watches over the medical device field. Parts made by CNC for implants or direct use need strict testing and approval. Companies must follow the FDA’s current Good Manufacturing Practices (cGMP) to keep their work safe.

ISO 13485: Ensuring Quality in Medical Device Production

The ISO 13485 standard is key for quality in medical device making. CNC shops aiming for the healthcare market must show they meet this standard. It covers clean rooms, sterility, and quality assurance steps.

The Role of Clean Rooms and Sterility in CNC Machining

The medical field needs top cleanliness and sterility to avoid contamination. CNC work for this sector happens in advanced clean rooms. These rooms control temperature, humidity, and particles. Sterilization steps are also crucial to keep products sterile.

Benefits of CNC Machining in Medical Device Production

The medical device industry needs top-notch precision, quality, and speed. CNC (Computer Numerical Control) machining has changed the game here. It brings many benefits that make production smoother and products better.

Speed and Precision for Prototyping and Production

CNC machining is a big win for medical device makers. It’s fast and accurate, speeding up product development. This means new devices hit the market quicker, which is key in a fast-paced industry.

Low-Volume Manufacturing for Custom Medical Devices

CNC machining is great for making small batches of custom devices. This is vital for things like orthopedic implants or dental prosthetics. It lets companies make these devices affordably, giving patients the care they need.

Reducing Material Waste in Medical Device Production

Reducing waste is crucial in medical device making. CNC machining is top-notch at this, cutting down on waste. This is good for the planet and helps keep costs low, making it a smart choice for makers.

Using CNC machining, medical device companies can make production faster, cheaper, and more efficient. This means they can offer the quality products that patients and healthcare providers expect.

Applications of CNC Machining in the Medical Field

CNC machining is key in the medical device world. It’s used for making orthopedic implants, dental devices, and surgical tools. This technology ensures these items are precise, safe, and fit well with the body.

Orthopedic Implants: Precision and Biocompatibility

Orthopedic implants, like joint replacements, need to fit perfectly and be safe. CNC machining makes these implants with high accuracy. This means they are comfortable and last a long time for patients.

Dental Devices: Custom Fit and High Precision

CNC machining has changed dentistry. It helps make dental devices like crowns and orthodontic appliances. These are made to fit each patient’s needs, offering a great fit and function.

Surgical Tools: CNC’s Role in Ensuring Safety

CNC machining is also used for surgical tools. These tools need to be precise and safe for surgeries. CNC makes these tools sharp and safe, reducing infection risks.

CNC machining is used in many ways in medicine. It helps make better implants, devices, and tools. This technology improves healthcare by making treatments more effective and safer.

Why Choose Shixinproto for Medical Device CNC Machining Services

Medical device manufacturing needs precision and quality. Shixinproto is a trusted partner for CNC machining in the medical field. They have years of experience and follow strict rules to deliver top results.

Shixinproto’s skilled team uses the latest CNC technology. They make many medical devices, like orthopedic implants and surgical tools. They focus on detail and quality to meet medical standards.

Shixinproto knows how important following rules is. They have the right certifications and clean rooms. This means their work meets FDA and ISO 13485 standards. Medical professionals trust Shixinproto for their expertise.

FAQ

What is the importance of CNC machining in medical device production?

CNC machining is key in making medical devices. It helps create parts that are precise and meet strict rules. This ensures devices are safe and effective for patients.

How does CNC machining contribute to the precision of medical devices?

CNC machining is known for its precision. It uses advanced technology to make parts with very small tolerances. This is crucial for devices like surgical tools and implants.

What are the common CNC machining processes used in medical device manufacturing?

Common CNC processes include milling, turning, and Wire EDM. Milling makes implants and instruments. Turning is for parts with tight tolerances. Wire EDM creates very precise components.

What are the regulatory requirements for CNC machining in the medical device industry?

CNC machining for medical devices must follow FDA and ISO 13485 rules. It must be done in clean rooms to keep products sterile. This ensures safety for patients.

How does CNC machining provide benefits in medical device production?

CNC machining is fast and precise, great for making prototypes and products. It’s also good for making small, custom devices. Plus, it reduces waste, making it vital for the industry.

What are some of the applications of CNC machining in the medical field?

CNC machining is used for many medical devices. It’s used for implants, dental devices, and surgical tools. These need to be precise and safe.

Why should medical device manufacturers choose Shixinproto for their CNC machining needs?

Shixinproto is a top choice for CNC machining in the medical field. They focus on precision, quality, and following rules. Their advanced CNC skills and knowledge of medical needs make them a great partner.